We’re relentlessly committed to passionate customer service, offering versatile operations and the industries’ most expansive national footprint.

Come ride the VORTEQ wave of momentum for your coil coating needs! Let’s get started at vorteqcoil.com

Features

buff.ly/3cKWgN1 #mfg #manufacturing

@IndustryWeek

ll signs point to a double-digit decline in second-quarter real GDP in the United States. Even if growth quickly returns during Q3, the downturn will still be the worst since the end of World War II. For 2020 as whole, real GDP is projected to fall 8.1 percent in the U.S., say IHS Markit economists Nariman Behravesh and Sara Johnson.

Although deep, “this [c]ould be the shortest recession on record (back to the 1850s) in the U.S.,” according to the consultancy. On the other hand, Behravesh and Johnson predict “the recovery is likely to be a hard slog [because] the fallout from this pandemic and the lockdowns can only be described as massive. The economic and social costs continue to rise and will stay elevated for a long time.”

n Tipton, Indiana—near where Elwood Haynes, inventor of the cobalt-steel alloy 6B, began his journey as a metallurgist—High Performance Alloys melts and processes the material from ingot to slabs, billet, bars and narrow plate, says Jeff Kirchner, manufacturing director and COO.

A: Having worked at Cabot for 20 years, our company founder (my father) was very familiar with Stellite products. 6B, UNS R30016, is the wrought version of R30006 or cast Stellite #6.

Thomas Boney has been appointed senior vice president of Novelis Inc., Atlanta, succeeding Marco Palmieri, who has become senior vice president and chief integration officer, leading the integration of Aleris into Novelis. Boney leads all aspects of the company’s North America business, which includes manufacturing and recycling facilities across the United States and Canada.

The Precision Metalforming Association elected Troy Turnbull, president and CEO of Industrial Innovations Inc. as 2020 chairman of the board of directors. Doug Johnson, president of Marion Manufacturing Co., will serve as vice chairman and treasurer. Both will serve one-year terms. Turnbull succeeds outgoing PMA board chairman Troy Roberts, CEO of Beanstalk CCW LLC,.

The L.S. Starrett Co., Athol, Massachusetts, appointed Jamie Feere as sales manager- Canada, industrial products; Michael Connor as strategic accounts sales manager in North America; and John Hibbard as regional sales manager western U.S., industrial products.

Behringer Saws Inc., Morgantown, Pennsylvania, hired John Herrick as an inside sales engineer. He previously worked for over 12 years in customer support. Robert Marshall was named field service manager. He has 10 years of electrical and machine technical support experience.

Leeco Steel, Lisle, Illinois, appointed Jeff Irby as e-commerce product manager and Owen Donaghey as digital commerce manager. These are newly created roles that will develop digital sales initiatives for the company.

New Day Aluminum Holdings LLC, Gramercy, Louisiana, the parent of Noranda Bauxite and Noranda Alumina, appointed John Habisreitinger as chief operating officer. He has over 30 years of experience in the aluminum and alumina sectors, serving most recently as executive vice president for New Day.

Mazak Optonics Corp., Elgin, Illinois, promoted Dan Konrath from applications engineer to its Southeast regional sales manager. He has five years of experience at Mazak Optonics, working in installations and applications, and was self employed for 15 years before that.

BLM Group, Wixom, Michigan, 248/560-0080, www.blmgroup.com.

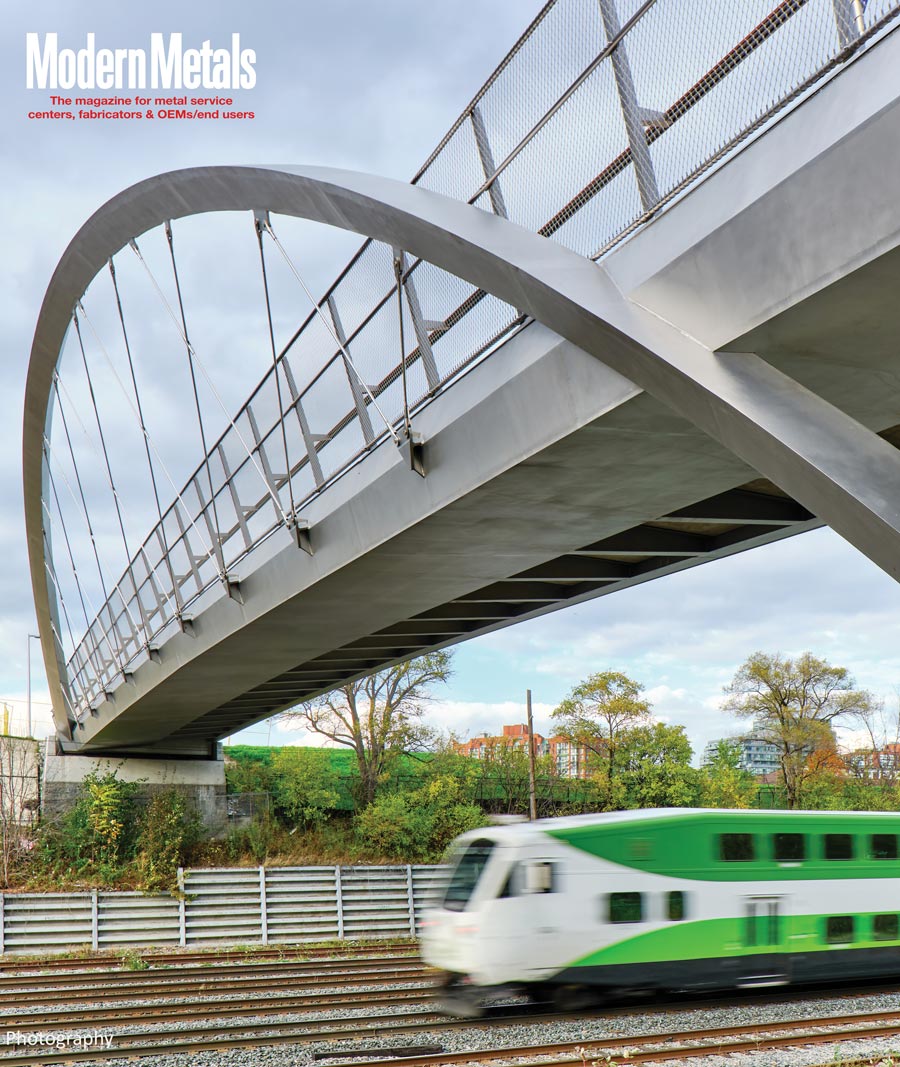

rom Montreal to Macau, stainless steel has proven to be a material of choice for the iconic structures that bridges represent. The projects outlined in an International Stainless Steel Forum report issued earlier this year range from small pedestrian bridges less than 100 meters long to those spanning 55 kilometers. We chose six of these to investigate.

rcelorMittal Tailored Blanks (AMTB) Americas produced 17 million laser-welded blanks last year. The great majority of those blanks were made using conventional blanking technology because it cuts and moves a high volume of steel very fast.

However, when the company is working directly with automotive engineers and designers to craft and perfect shaped steel sheets, and adapt to new part drawings on the fly, AMTB relies on its partner RDI Laser Blanking Systems to make that happen.

RDI builds coil-fed laser blanking lines and is a toll processor that uses its technology on behalf of customers to develop part designs.

lthough the global economy and the metals supply chain is suffering a direct hit as a result of the coronavirus outbreak, companies must strategize for the long term, for what comes after.

The manufacturing and distribution worlds were already heading toward a more thorough understanding of everything they do from purchasing to accounting and processing to delivery by accessing data. Data-driven decisions help companies heighten efficiencies and control costs.

“The metals industry is extremely competitive. There are low barriers to entry and thousands of competitors. The only way to succeed is to find efficiency,” says Matt Meyer, vice president of digital innovation for Kloeckner Metals Corp.

peed as well as finish prompted Laserfab in Lebanon, Pennsylvania, primarily a laser shop and metal fabrication operation, to invest in a waterjet cutting system. Customer demand required the capability to cut material with no heat affected zones or heat buildup on the surfaces and cut edges.

“Depending on how thick the parts are, it made more sense for us to invest in upgrading our existing waterjet rather than worry about secondary processing edges if parts are cut using one of our lasers,” says Anthony Martin, Laserfab’s director of operations.

lasertechnology

n November 1789, Benjamin Franklin wrote a letter to French physicist Jean-Baptiste Le Roy in which he penned the now familiar words, “…nothing is certain, except death and taxes.” More than two centuries later, change remains a constant, but it can also signal growth for companies able to adapt. Fort Wayne, Indiana-based Ottenweller Co. Inc. has parlayed flexibility and the capacity to adjust to different conditions into a business that has thrived for more than 100 years.

Ed Ottenweller established the company as a blacksmith shop in 1916 with just six employees. By the 1980s, it had evolved into a metal fabricator with 75 employees and a customer base that covered two-thirds of the United States.

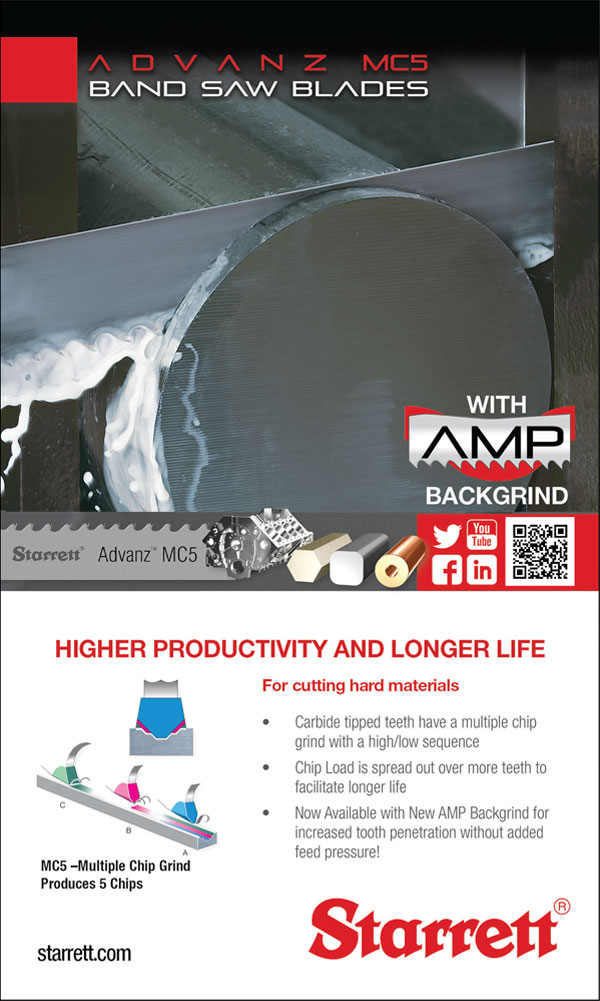

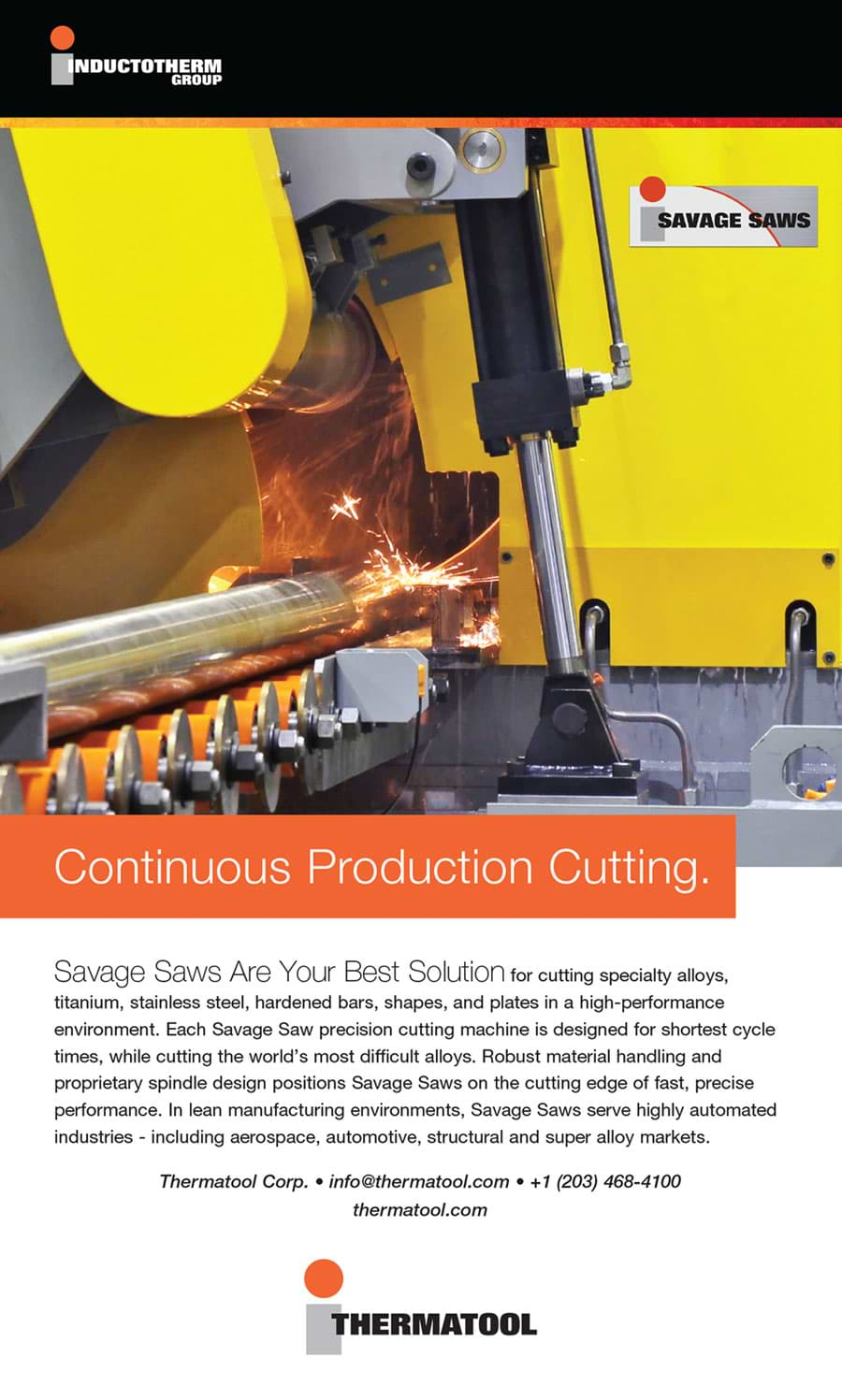

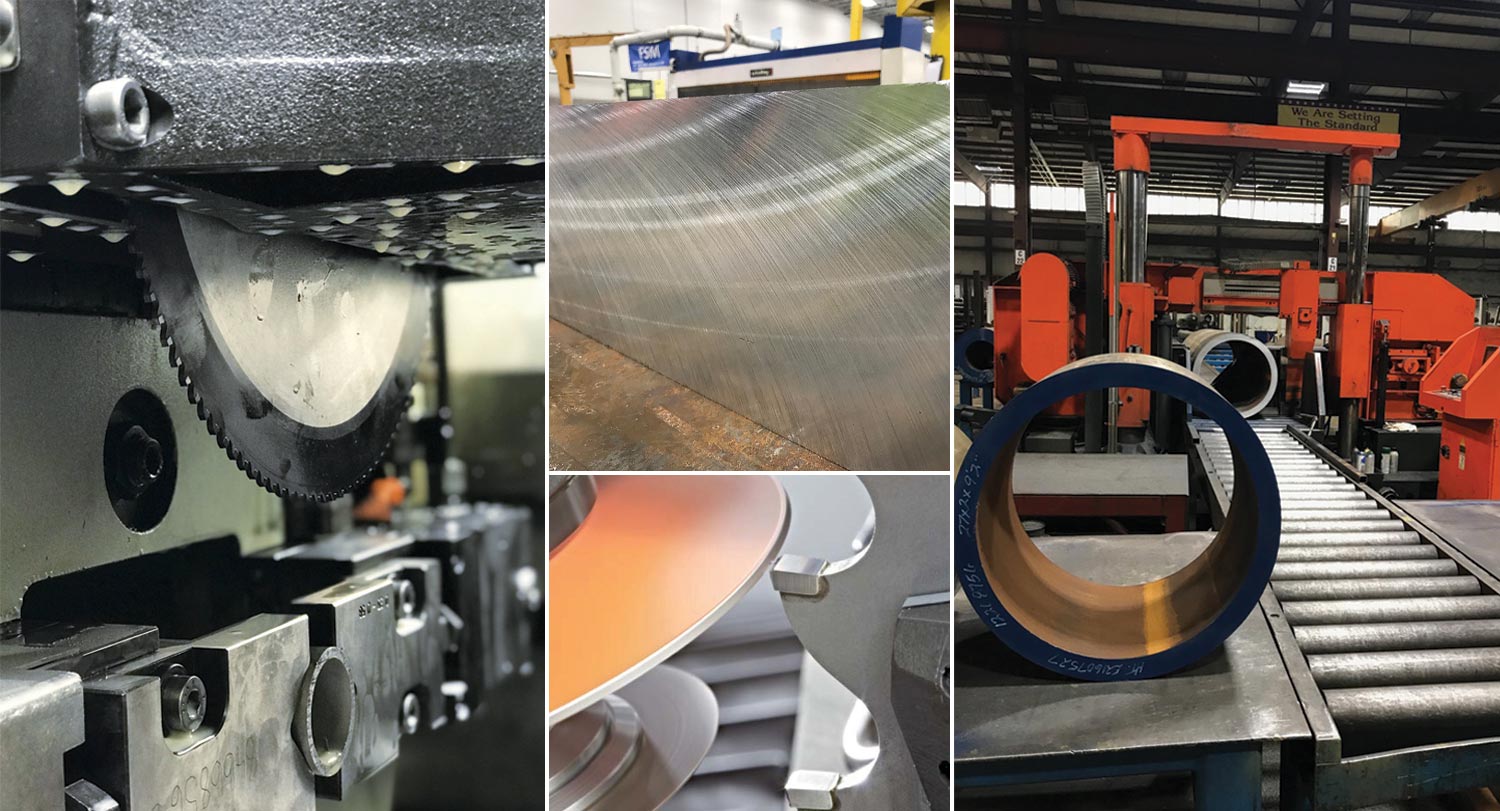

sawingtechnology

n the world of precision cutting, a one-size-fits-all approach is often popular because it’s easy—but it can leave an end user wanting more. Jordan Chynoweth, vice president of Phillips Saw & Tool, Frankfort, Indiana, believes it’s important for saw blade manufacturers to encourage their customers to move beyond these off-the-shelf solutions through collaboration and partnership with all the departments involved in cutting operations.

“Supporting end users with manufacturing consistency and transparency allows them to develop a plan to exploit their individual strengths while minimizing weaknesses,” Chynoweth says. “Obtaining lasting cost reductions, increased cutting performance and active operator participation are crucial to lasting success.”

Advertiser Index

View Index

partingshot

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.modernmetals.com

312/654-2309, Fax: 312/654-2323

mdalexander@modernmetals.com

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@modernmetals.com

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Oklahoma, Pennsylvania, South Carolina, South Dakota, Tennessee, Texas

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@modernmetals.com

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@modernmetals.com

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@modernmetals.com

Modern Metals® (ISSN 0026-8127, USPS 357-640) July 2020, Vol. 76, No. 6 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Modern Metals® (ISSN 0026-8127, USPS 357-640) July 2020, Vol. 76, No. 6 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.