newproducts

Laser cutting system updated with Active Tools

BLM Group has enhanced its LT Fiber EVO and CO2-type LT722D automatic laser cutting systems with Active Tools. These patented solutions automatically adapt process parameters for optimal results independent of operator experience. The suite of Active Tools included with machines include Active Tilt, Active Scan, Active Weld, Active Focus, Active Marking, Active Speed, and Active Piercing. The LT722D, available with a 2.5kW CO2 laser source, will cut carbon and stainless steel and aluminum. The LT Fiber EVO, available with a 2kW or 3kW fiber laser, can cut these materials plus copper, brass and galvanized steel.

BLM Group, Wixom, Michigan, 248/560-0080, www.blmgroup.com.

Time-saving tool cleaning and laser marking modules

To further increase efficiency of the manufacture and final inspection of cutting tools, Walter Helicheck Plus and Helicheck Pro machines include new modules for tool cleaning and laser marking. Both modules are incorporated into, and work in tandem with, the machine’s robot loader to shorten overall production time. The cleaning module runs tools through an ultrasonic bath, followed by airstream drying. After tools are cleaned and measured, the laser marking module imparts static or dynamic data on to tool shanks or end faces.

United Grinding North America, Miamisburg, Ohio, 937/859-1975, www.grinding.com.

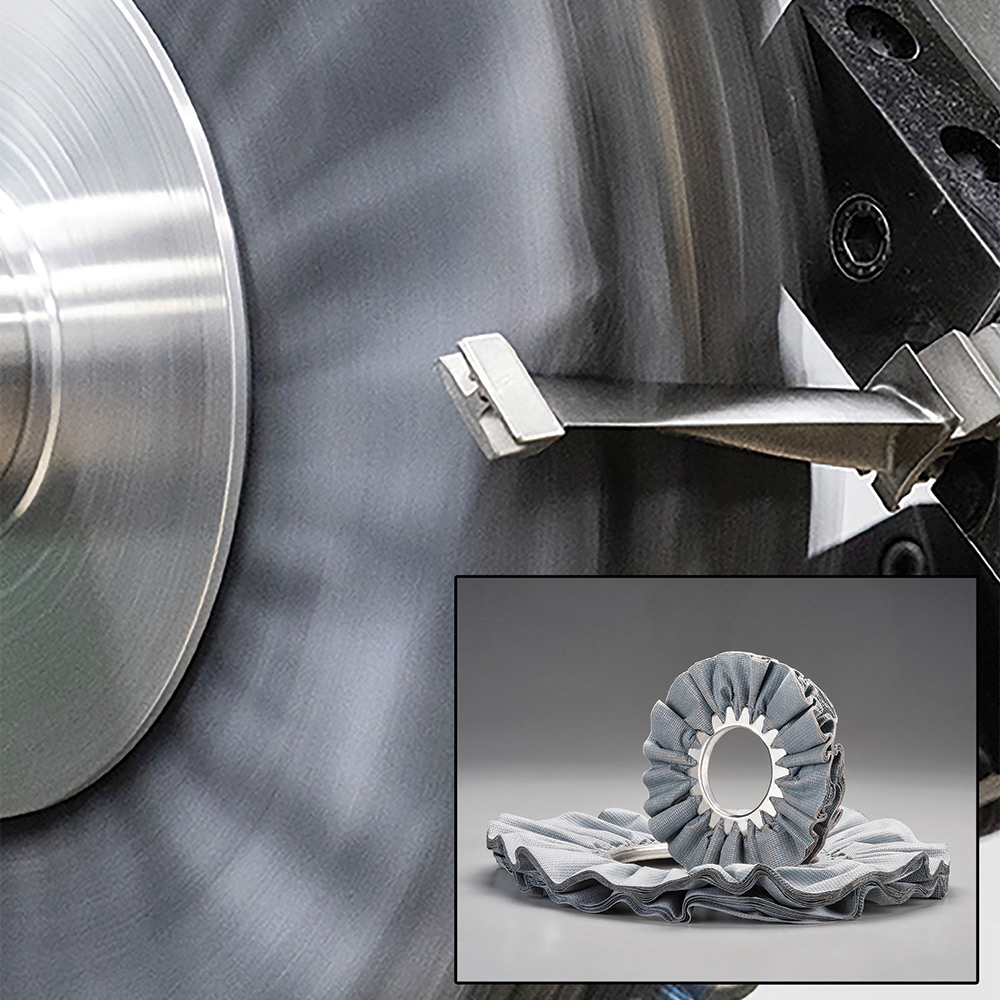

Buffing wheels improved

Norton FAB (fixed abrasive buff) buffing wheels virtually eliminate the need to use buffing compounds. Norton FAB wheels feature a patent-pending design that incorporates abrasive grains into the buffing wheel and consistently results in excellent values ranging from 1 to 5 Ra. The new Norton FAB wheels are tear resistant, waterproof and durable, providing significantly longer life than traditional cotton buffs.

Norton/Saint-Gobain Abrasives, Worcester, Massachusetts, 508/795-5000, nortonabrasives.com.

Tube and bar straightening system incorporates AI

A new automated, all-servo-controlled tube and bar straightening system incorporates artificial intelligence that automatically adapts by learning different part types without requiring operator intervention. The system has helped to reduce cycle times up to 80 percent compared to conventional approaches. Designed to manage carbon and stainless steels, aluminum, copper, brass and other materials, these system offers repeatable process for improved quality; reduced requirements for skilled operators; and decreased cycle times.

Coldwater Machine Co., Coldwater, Ohio, 419/678-4877, coldwatermachine.com.