sawingtechnology

n the world of precision cutting, a one-size-fits-all approach is often popular because it’s easy—but it can leave an end user wanting more. Jordan Chynoweth, vice president of Phillips Saw & Tool, Frankfort, Indiana, believes it’s important for saw blade manufacturers to encourage their customers to move beyond these off-the-shelf solutions through collaboration and partnership with all the departments involved in cutting operations.

“Supporting end users with manufacturing consistency and transparency allows them to develop a plan to exploit their individual strengths while minimizing weaknesses,” Chynoweth says. “Obtaining lasting cost reductions, increased cutting performance and active operator participation are crucial to lasting success.”

“We are striving to reshape the supplier/end-user relationship,” Chynoweth notes. “Phillips Saw provides cost savings through specialized programs for educating operators on the proper maintenance and use of sawing equipment, technological advances and flat cost reductions,” and he believes this relationship can be expanded to accomplish more.

We guarantee a minimum 15 percent cost reduction with our VMI programs.

We guarantee a minimum 15 percent cost reduction with our VMI programs.

Phillips Saw’s custom VMI programs highlight areas where costs can be reduced: provide forecasts for budgets, ensure goals and objectives are being accomplished; train operators to better understand productive sawing principles; use material data to apply specific saw blades to product ranges or part numbers; and create service schedules that highlight common wearable items that directly affect blade performance.

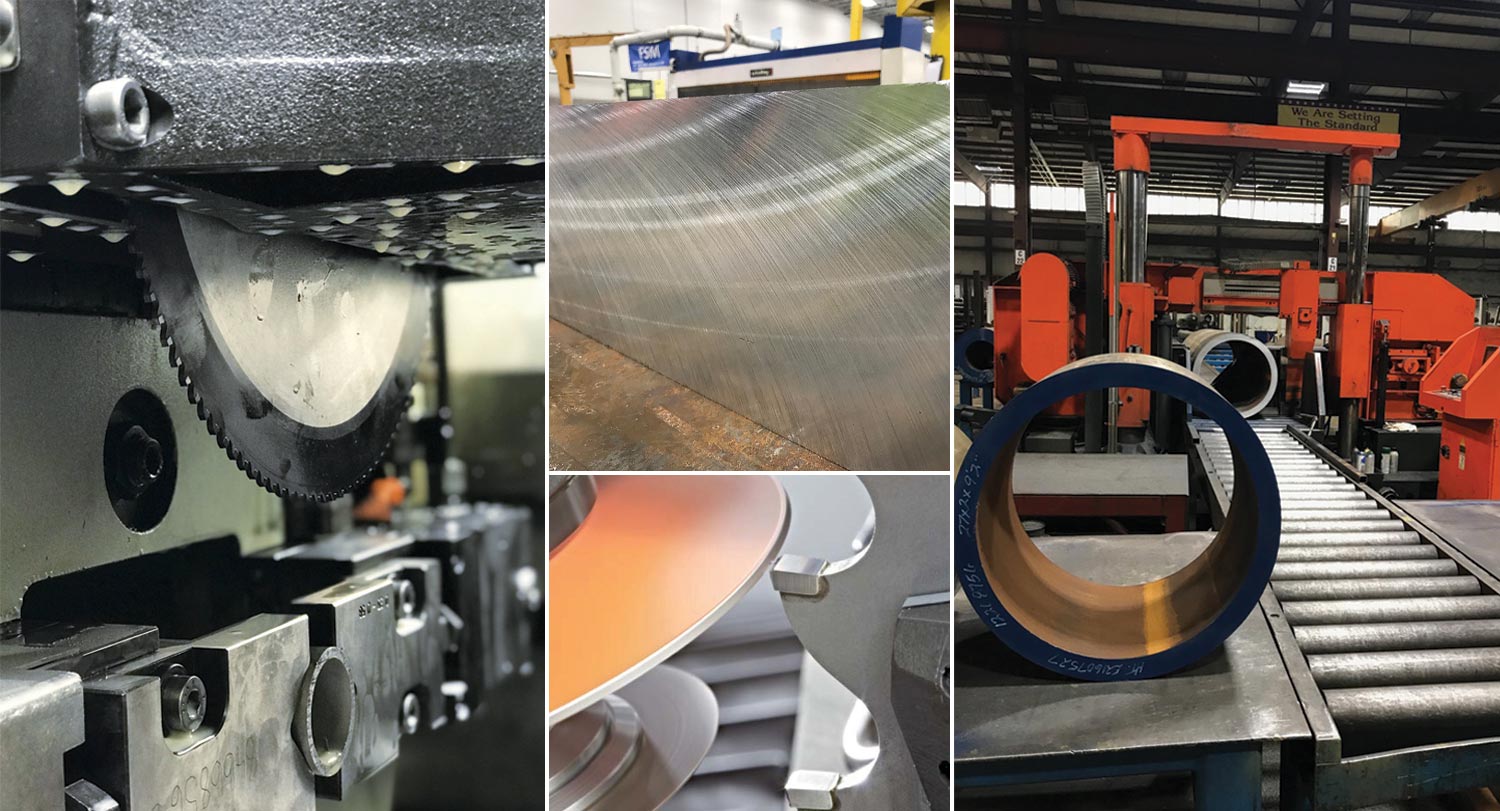

Phillips Saw also provides video analysis and imaging printouts to ascertain areas of concern with tooling, recording blade serial number, machine and department. “We advise on what could be causing issues and then examine the cutting operation to determine if the logic matches,” Chynoweth explains.

“Material placement, clamping, speed/feed rates, surface finish, cutting sound and chip formation are all discussed,” Chynoweth says. “We provide handouts with terminology and illustrations, and if a location uses multiple blade designs, each unique feature is discussed. We also cover potential limitations and how to address them.”

The VMI program’s operational transparency allows end users to “easily see when operators are applying recommendations or if mechanical issues are arising due to excessive blade repair,” Chynoweth says. “Typically, we guarantee a minimum of 15 percent total reduction of costs associated with our custom VMI programs.”

“In this case, the manufacturer made new capital investments in specialized sawing equipment in late 2019,” Chynoweth says. “Together with on-site support, inventory management and Phillips-built custom tooling, the manufacturer created a roadmap to manage its consumption of saw blades.”

Phillips Saw calculated exactly how many square inches of material removal were required to achieve the forecasted production. With this data, a detailed analysis of the number of tools and service intervals required to reach this goal was identified, and Phillips removed the burden of configuring cost and inventory requirements, normally borne by the end user.

“If your current saw blade provider is not helping you advance your business, then they are not valuing true partnership,” Chynoweth says. “Communication and transparency allow manufacturers to be realistic with production goals, budgets and operation mentality. We partner with each end user wholeheartedly, recognizing we advance with them. We continually invest in improving our products and processes, and our total customer experience makes it easy for end users to be completely in the know about their sawing operations.”