rcelorMittal Tailored Blanks (AMTB) Americas produced 17 million laser-welded blanks last year. The great majority of those blanks were made using conventional blanking technology because it cuts and moves a high volume of steel very fast.

However, when the company is working directly with automotive engineers and designers to craft and perfect shaped steel sheets, and adapt to new part drawings on the fly, AMTB relies on its partner RDI Laser Blanking Systems to make that happen.

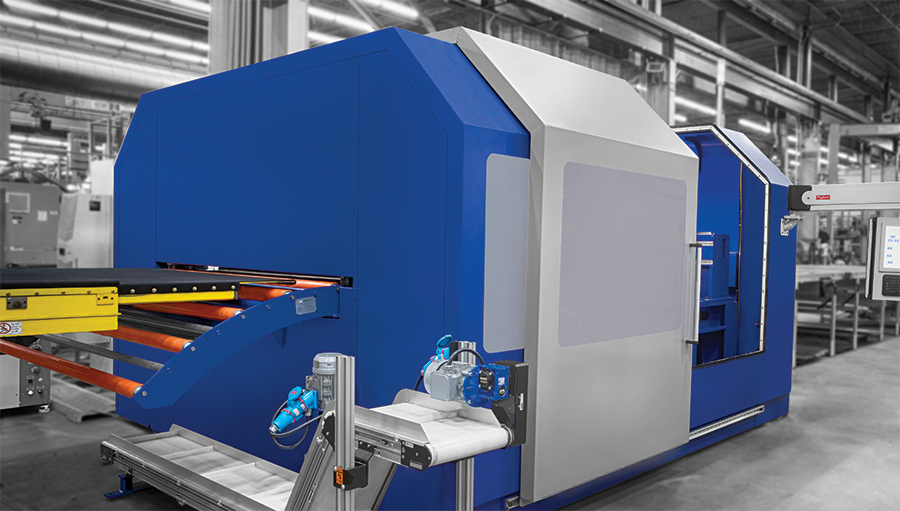

RDI builds coil-fed laser blanking lines and is a toll processor that uses its technology on behalf of customers to develop part designs.

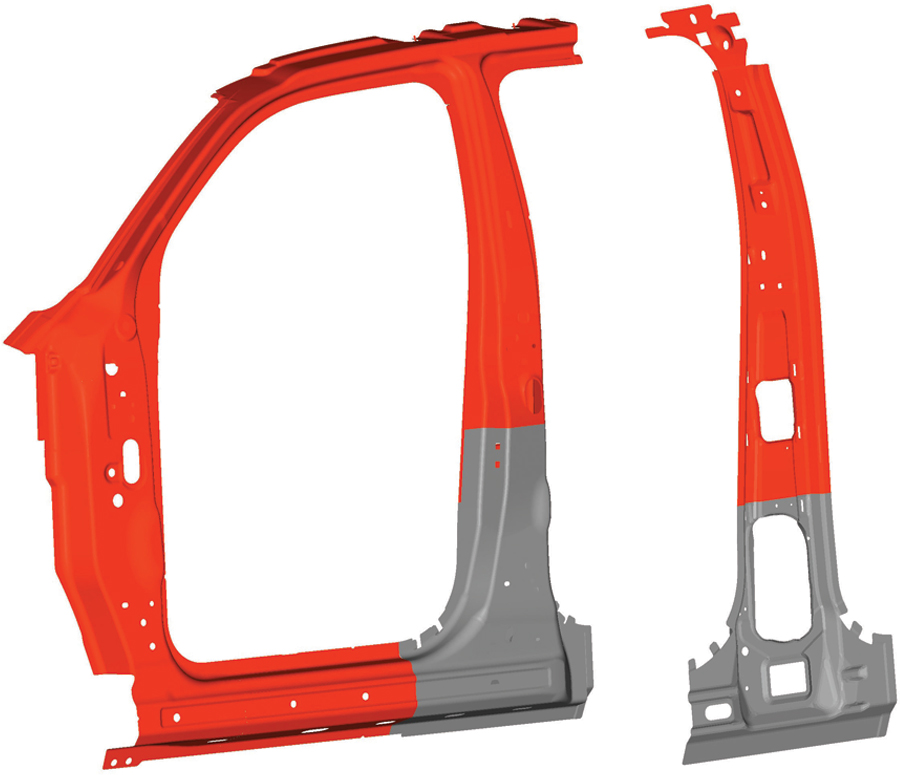

AMTB buys coils from its parent company and from other producers of automotive grades. It produces blanks of different shapes, sizes and strengths, then welds several of these together. The welded blanks then go to a Tier I hot stamper, which forms such components as A and B pillars, roof rails and door rings for automakers like FCA and Honda, according to Gary Black, director of advanced manufacturing technology for ATMB Americas. Plants are located in Detroit; Woodstock and Toronto, Ontario; and Silao, Mexico.

“We weld four or five pieces of different shapes to make a door ring,” Black says, “so when we send that piece to a stamper, our finished part can be as large as 2 meters by 2 meters with different complex shapes and different strengths, depending on where the strength is needed. Strength and rigidity are needed for different collision tests.” A finished part will also include lighter-gauge steels to reduce weight where strength is not as critical, he says.

“We work with the OEM to design the parts to best suit crashworthiness and create lightweight structural components. Most of the grades we use are press-hardened steel, Usibor 1500 and Ductibor 500 for energy absorption,” Black says. The latter is less rigid but absorbs energy to prevent the structure from moving into the passenger compartment during a collision.

Due to the complexity of changing trim lines from design to ultimate production, RDI’s short runs of test blanks provide AMTB with the flexibility needed to work with customers “to get an exact shape for mass production before blank dies are built,” he says. “Trim dies are expensive to change. We can produce a flexible part and our customer can make tweaks first, then sign off on the final design. We then design the die that works,” Black explains. “We use the laser blanking process as proof of concept—and we can use production coils to do that.

“The real benefit is the flexibility to make design changes almost on the fly, which doesn’t require expensive modifications,” he says.

By providing the laser cutting as a service, RDI is able to continuously improve its equipment offering while also supplying its customers’ customers with high-quality parts, says Shankaran Shanmugabaskaran, RDI Laser Blanking Systems’ senior vice president of sales. “With a die tryout for an automotive customer like AMTB, you receive drawing revisions through the quoting and final cutting process. We add these updated drawings to our nesting software to make a new cutting program.

“Coil-fed laser blanking technology enables manufacturers to streamline their engineering development-to-production process. Whether it is ArcelorMittal or its automotive customers, we must be flexible and turn parts around quickly,” he notes. Tier 1 suppliers can use this flexible technology to support multiple customers and their specific project needs.

Often, spare replacement parts are needed years after the vehicle is built. Traditionally, this means all part dies must be stored, along with various coil widths that match these dies. With a coil-fed laser blanking system, all the parts from a given material thickness can be run on the same master coil, and die storage real estate becomes laser cutting instructions that can be saved in the cloud or on a USB thumb drive.

“We had customers with die problems mid-production and were able to get them running in a couple hours,” Shanmugabaskaran says. This was possible because several customers have coils on standby at RDI and because RDI can move rapidly from drawing to programming to cutting. For those reasons, even a traditional blanking house can benefit from having a coil-fed laser blanking line, he adds.

Customers appreciate that they are consuming less material due to scrap reduction and optimized nesting. “The flexibility and versatility of this technology spans beyond quick design changes,” Shanmugabaskaran says.

“We spend an extensive amount of time producing a weld-ready edge so it’s critical that the edge is straight and dimensionally accurate. All of the testing and prototypes we have done with RDI produced quality results on both edge condition and dimensional accuracy,” says Black.

Shanmugabaskaran agrees that laser-cut blanks must hold high dimensional tolerances. “If the blank is not dimensionally accurate, there will be issues with the welding and lead to a scrap situation downstream. The coil-fed laser blanking system is a highly repeatable and accurate part production solution.”

Black says his company is satisfied with RDI’s customer service. “Their feedback has been really great. They provide quick turnaround with our questions. If we tell them to make 500 parts in a particular shape, and we weld and ship to the customer and the customer wants to change a trim, we adjust the CAD file to make more parts with that different shape, and it’s easily done,” he says.

Another feature Black finds useful is that a lot of RDI’s components are locally sourced and “easy for a company running in North America to obtain. If we buy from Europe, we face a longer delivery time.” Regionally sourced machine components “reduce downtime and reduce the cost,” he says.

RDI Laser Blanking Systems, Itasca, Illinois, 630/274-0600, rdilaserblanking.com.