We’re relentlessly committed to passionate customer service, offering versatile operations and the industries’ most expansive national footprint.

Come ride the VORTEQ wave of momentum for your coil coating needs! Let’s get started at vorteqcoil.com

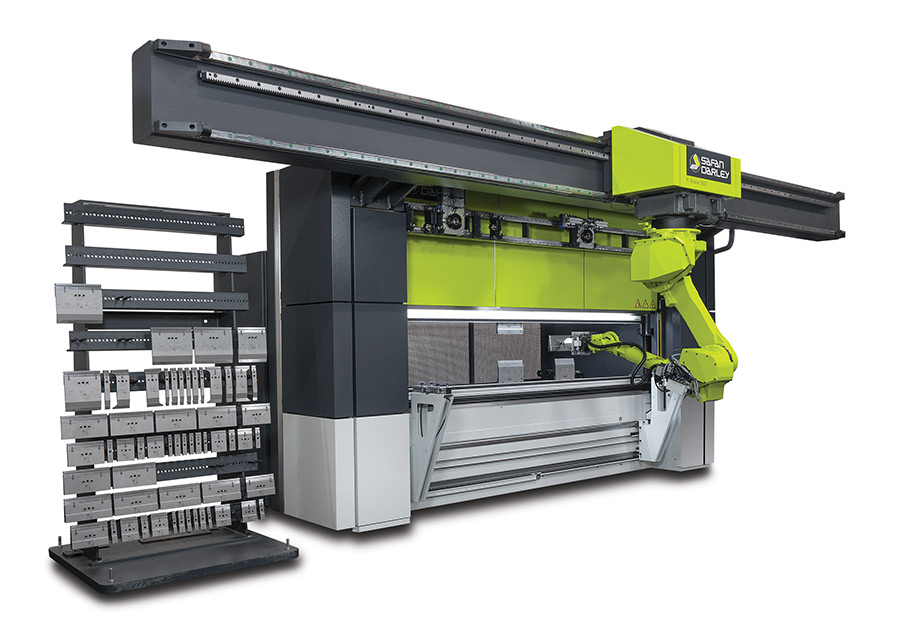

Features

ow.ly/sltO30rg0wP

@IntEngineering

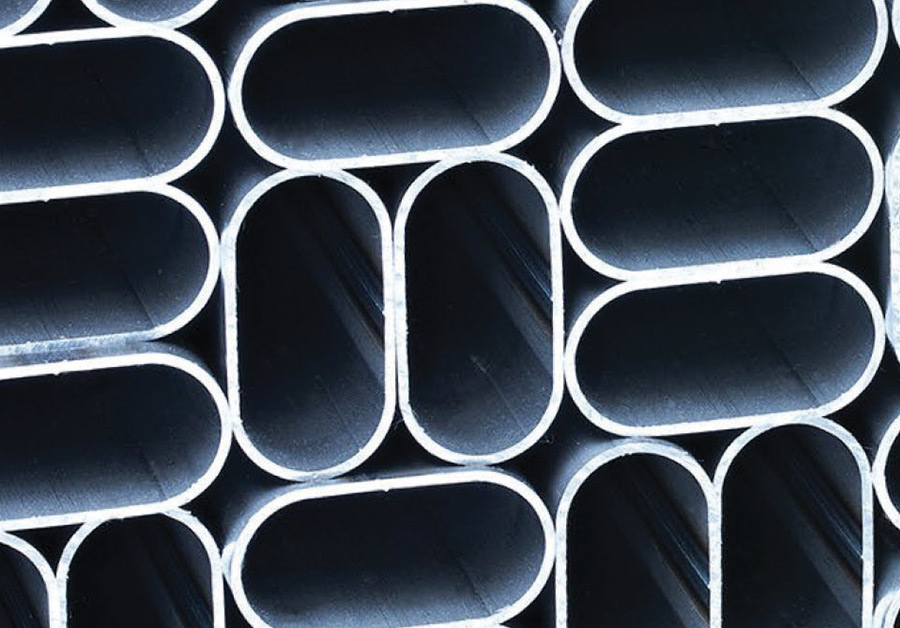

he World Steel Association updated short-range outlook has become more optimistic for 2021 than its previous version issued in June. While a decline in demand for 2020 is forecast, the decline is less severe than previously expected.

In 2020, worldsteel forecasts that steel demand will contract by 2.4 percent, dropping to 1.725 billion metric tons, due to the COVID-19 pandemic. In 2021, steel demand is expected to recover to 1.795 billion metric tons, an increase of 4.1 percent over 2020.

The post-lockdown recovery in steel demand outside China has been stronger than was earlier expected, but it still marks a deep contraction, both from developed and emerging economies, with only a partial recovery expected in 2021.

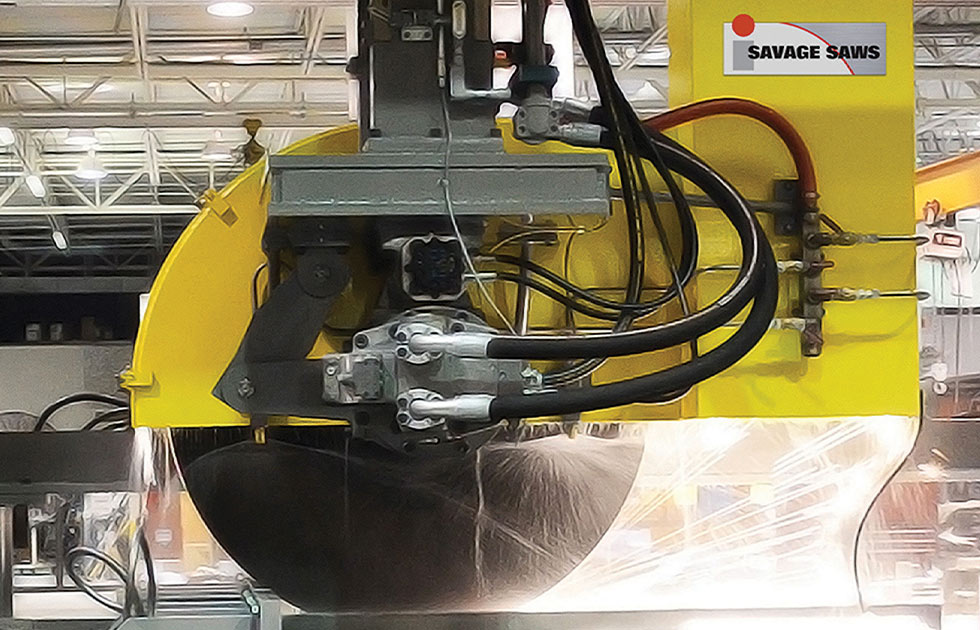

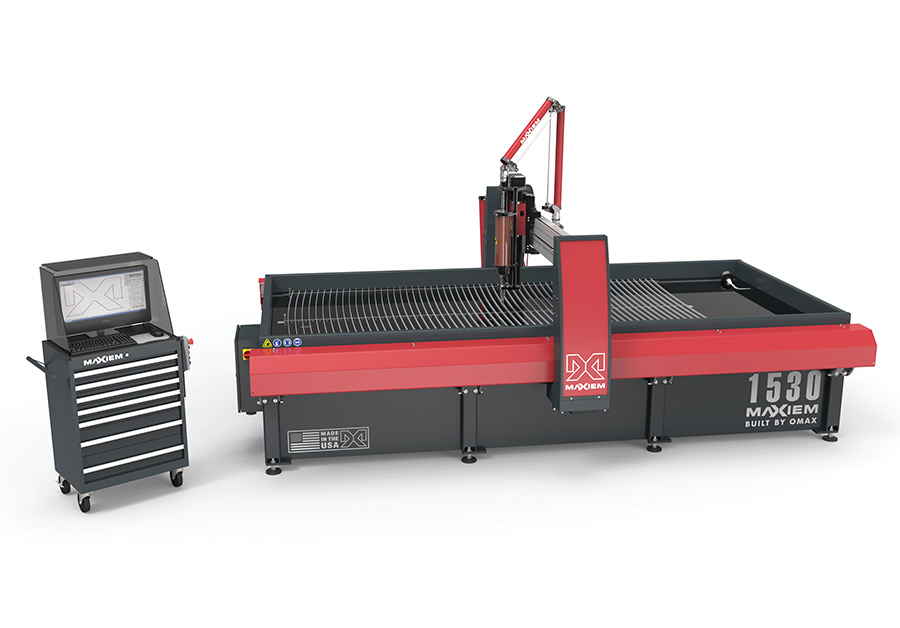

hat are the first thoughts that come to mind about the word “band saw”? If you are like most people, you think of up and down, left and right, horizontal and vertical machines. But that’s the funny thing about time and progress—things change rapidly.

Today’s machines have become much more sophisticated, thanks in part to the Internet of Things. These advancements allow more sophistication and an ability to download work to machines from a central ERP system, as well as inventory monitoring. IoT also permits supervisors to monitor saw activity and productivity from mobile devices.

But perhaps the biggest change has come with the advent of a new series of saws that allow almost near-net shaping for various industry sectors. Take the new Radius series of vertical machines offered by Friggi. These machines are capable of cutting a variety of radii and angles and even some shapes. This ability ensures that at the start of a part, the most basic, and usually most cost-effective machine, renders a near-net shape prior to going to a more sophisticated and costly milling operation.

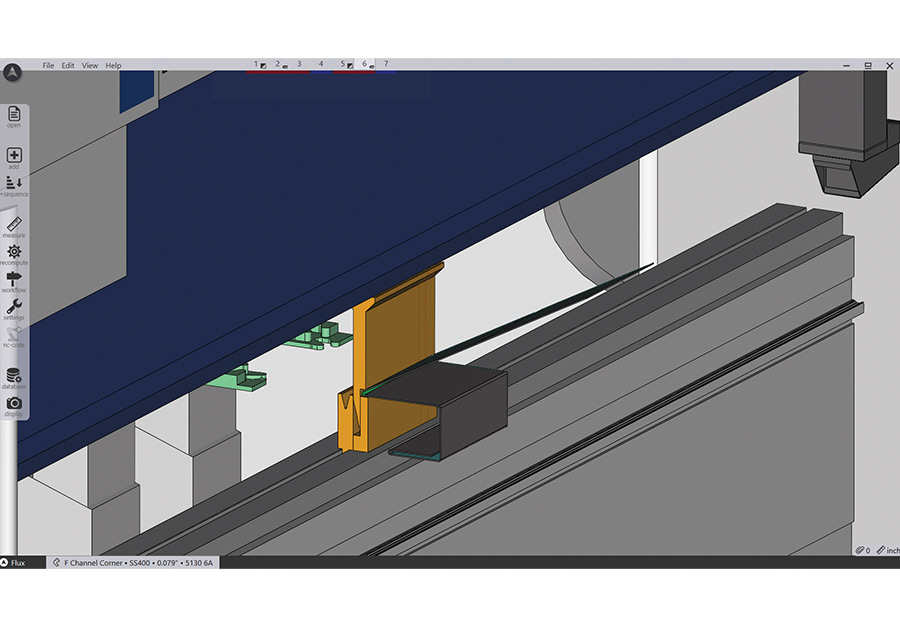

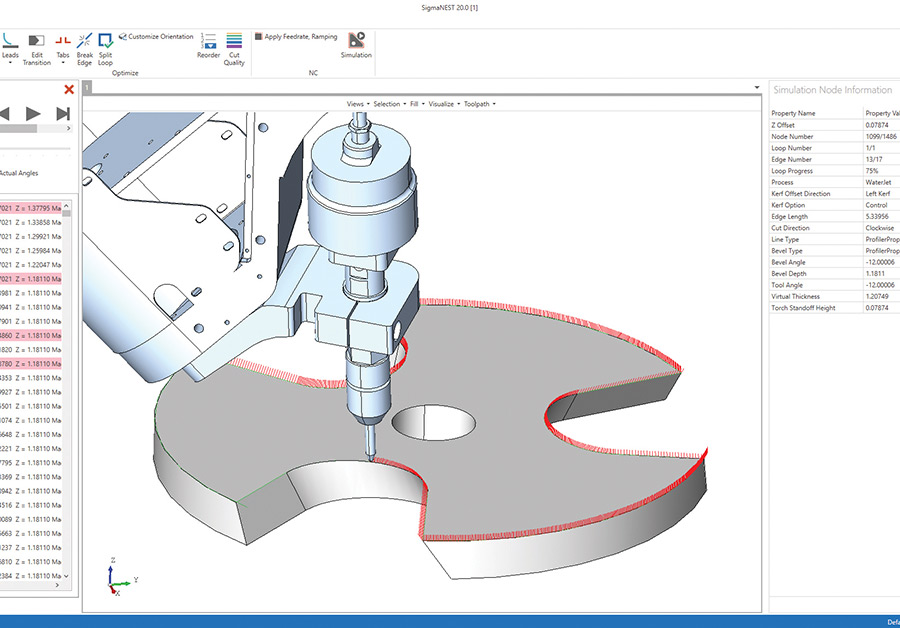

Sheet processor implements ERP system

Cleveland-Cliffs inks deal to buy ArcelorMittal USA

Cleveland-Cliffs Inc. has signed an agreement with ArcelorMittal S.A., Luxembourg, under which Cliffs will acquire substantially all of the operations of ArcelorMittal USA LLC and its subsidiaries for about $1.4 billion. Upon closing the transaction, Cleveland-Cliffs will be the largest flat-rolled steel producer in North America, with combined shipments of 17 million tons in 2019. The company will also be the largest iron ore pellet producer in North America, with 28 million long tons of annual capacity.

OBITUARY: John Paleczny, 72, retired former president of Petersen Aluminum Corp., Elk Grove Village, Illinois, died Oct. 18. Paleczny worked for Petersen for 49 years from 1970 to 2019, while overseeing revenue growth from $3 million to more than $170 million when he retired. He joined Petersen on the anodizing crew and gradually rose to the position of president, working closely with founder Maurice Petersen and, later, with his son Mike Petersen.

Peter Neuberger has been named president and CEO of United Performance Metals. Neuberger spent the past three years as president of G&L Tube, another part of O’Neal Industries. He has long management experience within industrial distribution and metals.

Damon J. Wos has joined Olympic Steel Inc., Cleveland, as general manager for the Schaumburg, Illinois, and Gary, Indiana facilities. Wos previously served as a general manager for Central Steel & Wire Co., Chicago.

Leeco Steel, Lisle, Illinois, appointed Lisa Liarakos as chief financial officer and member of the executive management team. Liarakos replaces CFO Mark Krzmarzick, who will retire at the end of the year.

O’Neal Steel, Birmingham, Alabama, promoted Clay Hosmer to vice president of sales and marketing. He succeeds Tate Forrester, who was recently promoted to president and CEO.

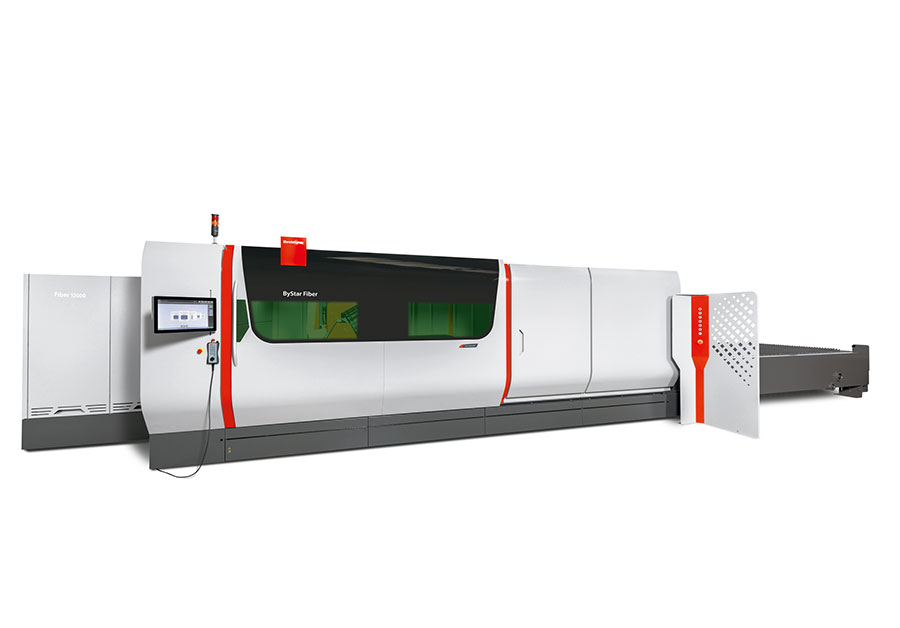

Zack Morrison has joined Bystronic Inc., Hoffman Estates, Illinois, as a direct sales engineer for the Oklahoma and Kansas territories. Morrison has over 10 years of direct manufacturing industry experience in sales management and CNC production.

Kathi Beach joins Cleveland Metal Exchange, Twinsburg, Ohio, as a sales representative, bringing 16 years of metal industry experience with her, including with a national service center chain.

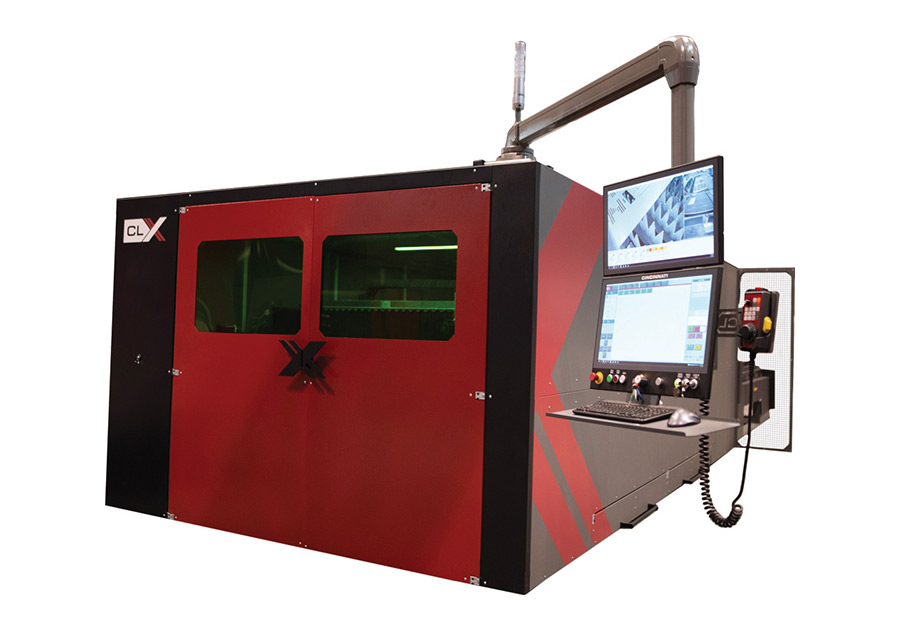

Mary Bopp has joined MC Machinery, Elk Grove Village, Illinois, as marketing coordinator. Bopp will support the marketing department, the website, marketing automation and events.

Equipment manufacturer Automatic Feed Co. promoted Joe Andriette to director of sales and marketing. Andriette has worked for Automatic Feed for 20 years, most recently as global sales account manager. The company also named Derek Faber as manager for its Automation Integration Manager (AIM) software offering. Faber has been a software engineer and IT support specialist at Automatic Feed for the past year.

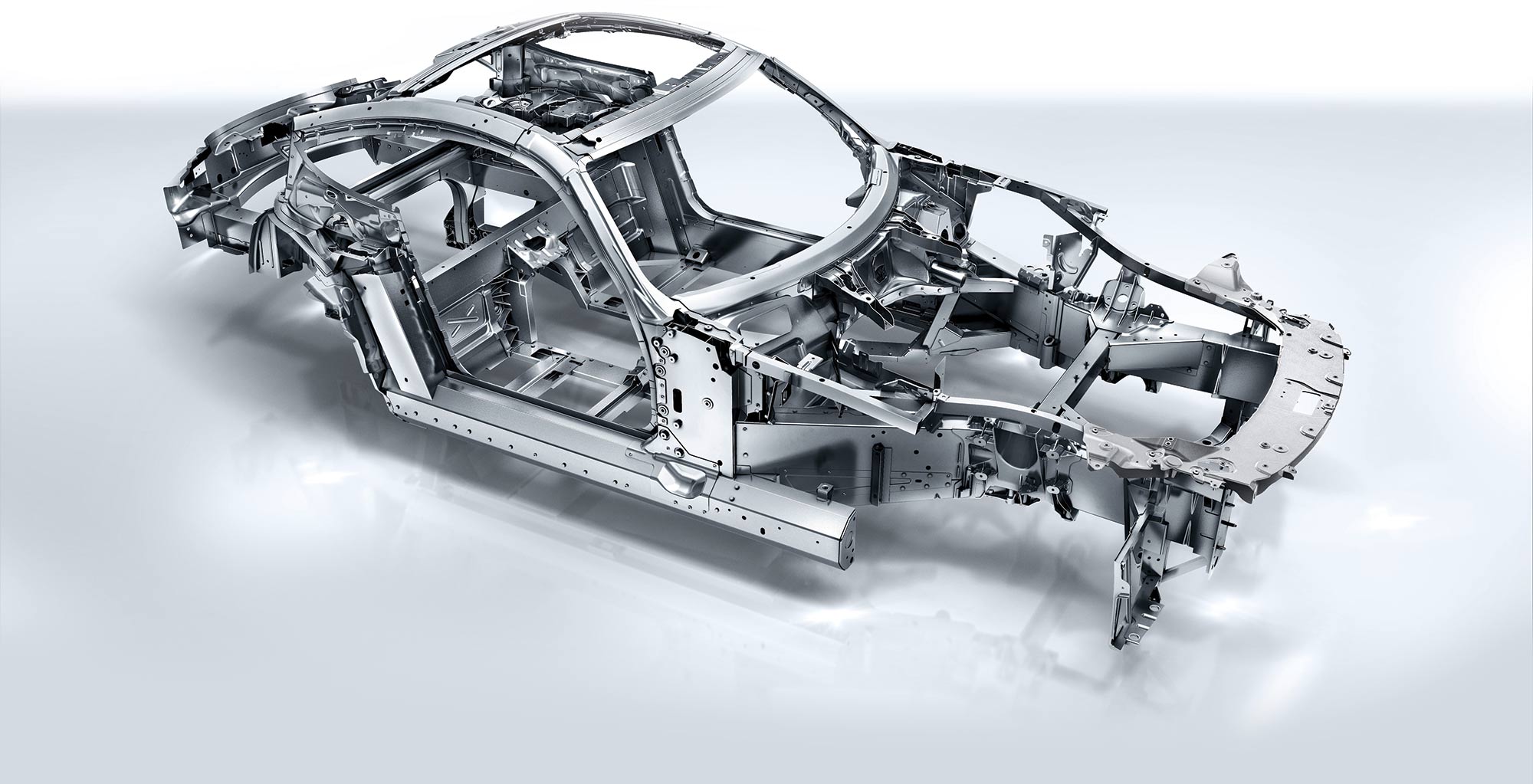

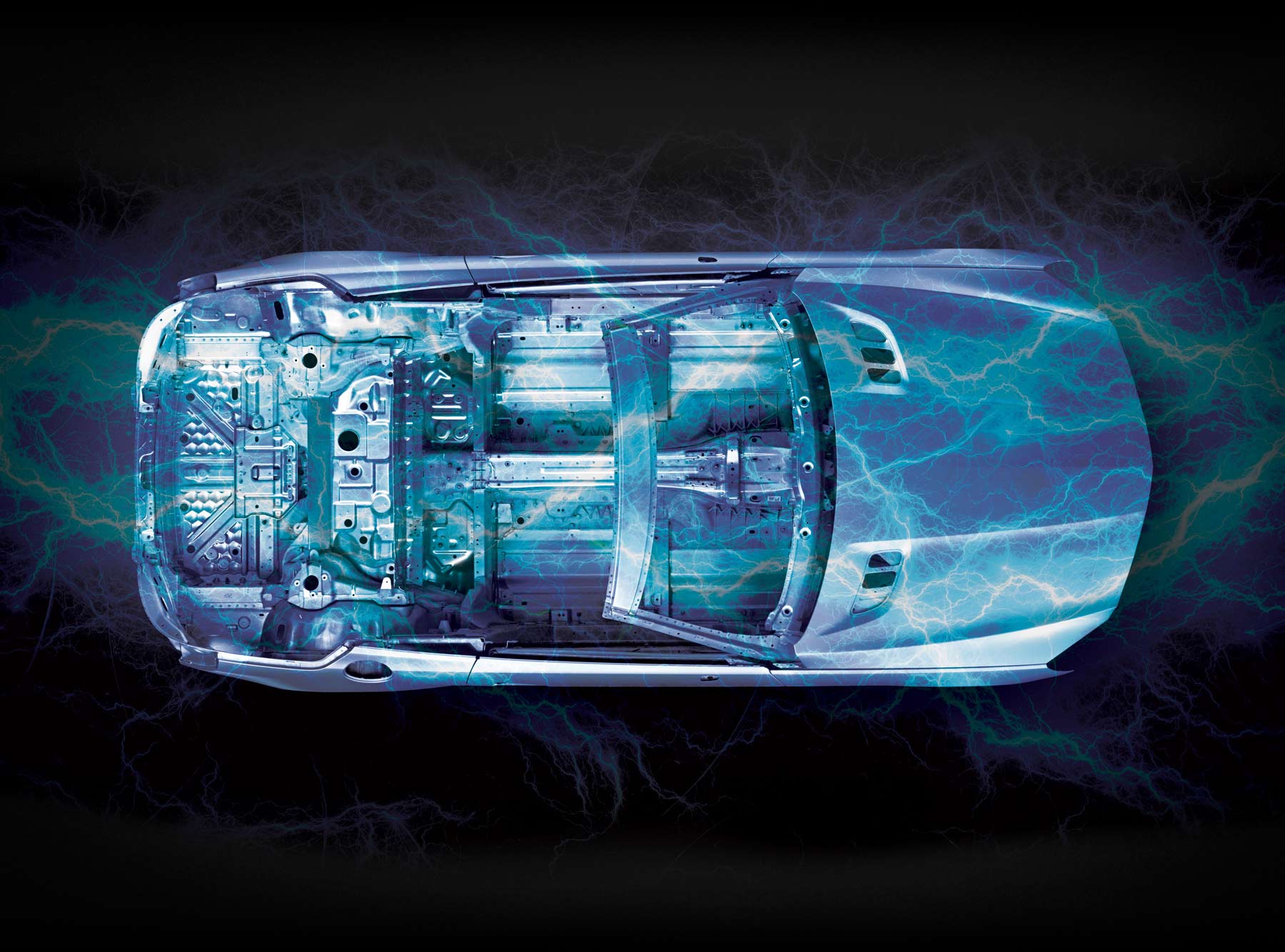

ere for you. That was a key message shared during a Sept. 30 webinar given by the Aluminum Association that focused on the future of vehicle lightweighting.

ere for you. That was a key message shared during a Sept. 30 webinar given by the Aluminum Association that focused on the future of vehicle lightweighting.

“DuckerFrontier interviewed participants throughout the automotive value chain, including automakers. Data tells us that aluminum will remain the fastest-growing material as a way to reduce mass. Whether you are working on an electric vehicle or designing a multi-material vehicle, the aluminum industry is here for you,” Dobbins said.

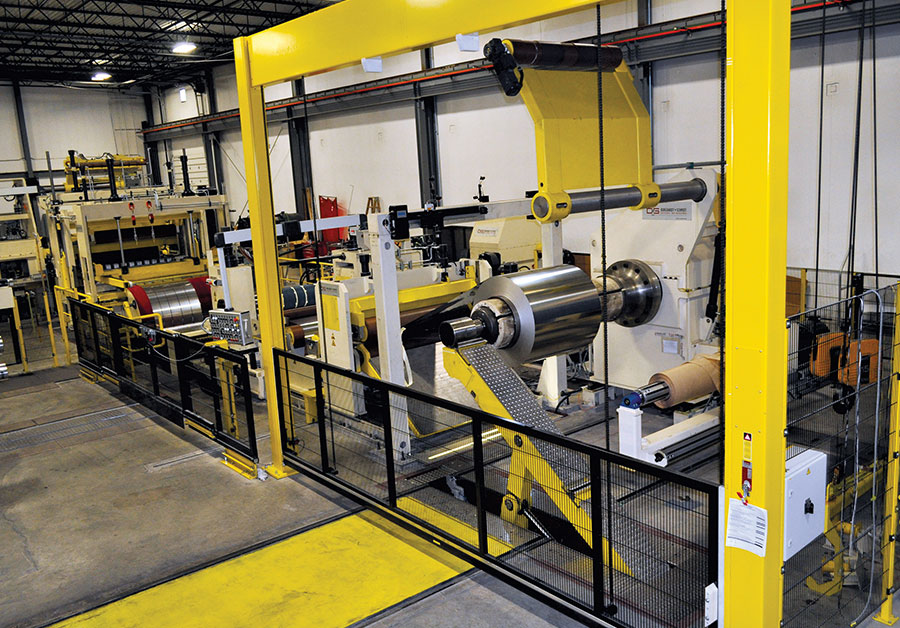

n a town with a long history, it might be difficult to imagine how successful a relative startup would become in less than 20 years. Camden, New Jersey, began life as a fort in 1626. Camden Yards Steel Co. was founded 375 years later. But CEO Mike Amato and President Alan Kanoff understood they could carve out a niche by leveraging their expertise in flat-rolled products.

“We previously worked for a family owned service center that was bought out by Metals USA Inc. After we worked there awhile, we realized that as metal distributors got bigger and bigger, there was a place for a boutique-style service center with a regional focus,” Amato says. “We chose Camden—that is, Camden picked us because they wanted us to be an anchor” for an industrial development on the Delaware River.

“We have the ability to unload our own ships and the ability to unload 20 railcars a day.” Being able to bring steel straight into the warehouse from the railroad and port is a “huge benefit” in terms of freight savings, he says.

nd those that paint them truest, praise them most,” is the last line of “The Campaign” by 18th century poet Joseph Addison. Three recent building projects, featuring the latest technology in both metal coating and architectural design, “paint” their attributes truest. The projects include a college science center, a high-rise mixed-use building in the Meatpacking District of New York City and a stadium in Florida.

nd those that paint them truest, praise them most,” is the last line of “The Campaign” by 18th century poet Joseph Addison. Three recent building projects, featuring the latest technology in both metal coating and architectural design, “paint” their attributes truest. The projects include a college science center, a high-rise mixed-use building in the Meatpacking District of New York City and a stadium in Florida.

CMBA Architects and HGA collaborated on designing Northwestern College’s $24.5 million DeWitt Family Science Center in Orange City, Iowa. When choosing the material for the exterior, the architects kept in mind that most of Northwestern’s buildings are brick, but created a modern facility that sets the tone for Northwestern’s future. The 61,000-square-foot building’s main focal feature is a cantilever, which called for a low-weight material. Coated metal was chosen for its weight-to-strength ratio.

The three-story science center houses classrooms, research laboratories, human patient simulators, faculty offices and a 960-square-foot greenhouse. The structure serves the biology, chemistry and nursing departments, the latter of which was previously housed in a nearby hospital.

nd those that paint them truest, praise them most,” is the last line of “The Campaign” by 18th century poet Joseph Addison. Three recent building projects, featuring the latest technology in both metal coating and architectural design, “paint” their attributes truest. The projects include a college science center, a high-rise mixed-use building in the Meatpacking District of New York City and a stadium in Florida.

nd those that paint them truest, praise them most,” is the last line of “The Campaign” by 18th century poet Joseph Addison. Three recent building projects, featuring the latest technology in both metal coating and architectural design, “paint” their attributes truest. The projects include a college science center, a high-rise mixed-use building in the Meatpacking District of New York City and a stadium in Florida.

CMBA Architects and HGA collaborated on designing Northwestern College’s $24.5 million DeWitt Family Science Center in Orange City, Iowa. When choosing the material for the exterior, the architects kept in mind that most of Northwestern’s buildings are brick, but created a modern facility that sets the tone for Northwestern’s future. The 61,000-square-foot building’s main focal feature is a cantilever, which called for a low-weight material. Coated metal was chosen for its weight-to-strength ratio.

The three-story science center houses classrooms, research laboratories, human patient simulators, faculty offices and a 960-square-foot greenhouse. The structure serves the biology, chemistry and nursing departments, the latter of which was previously housed in a nearby hospital.

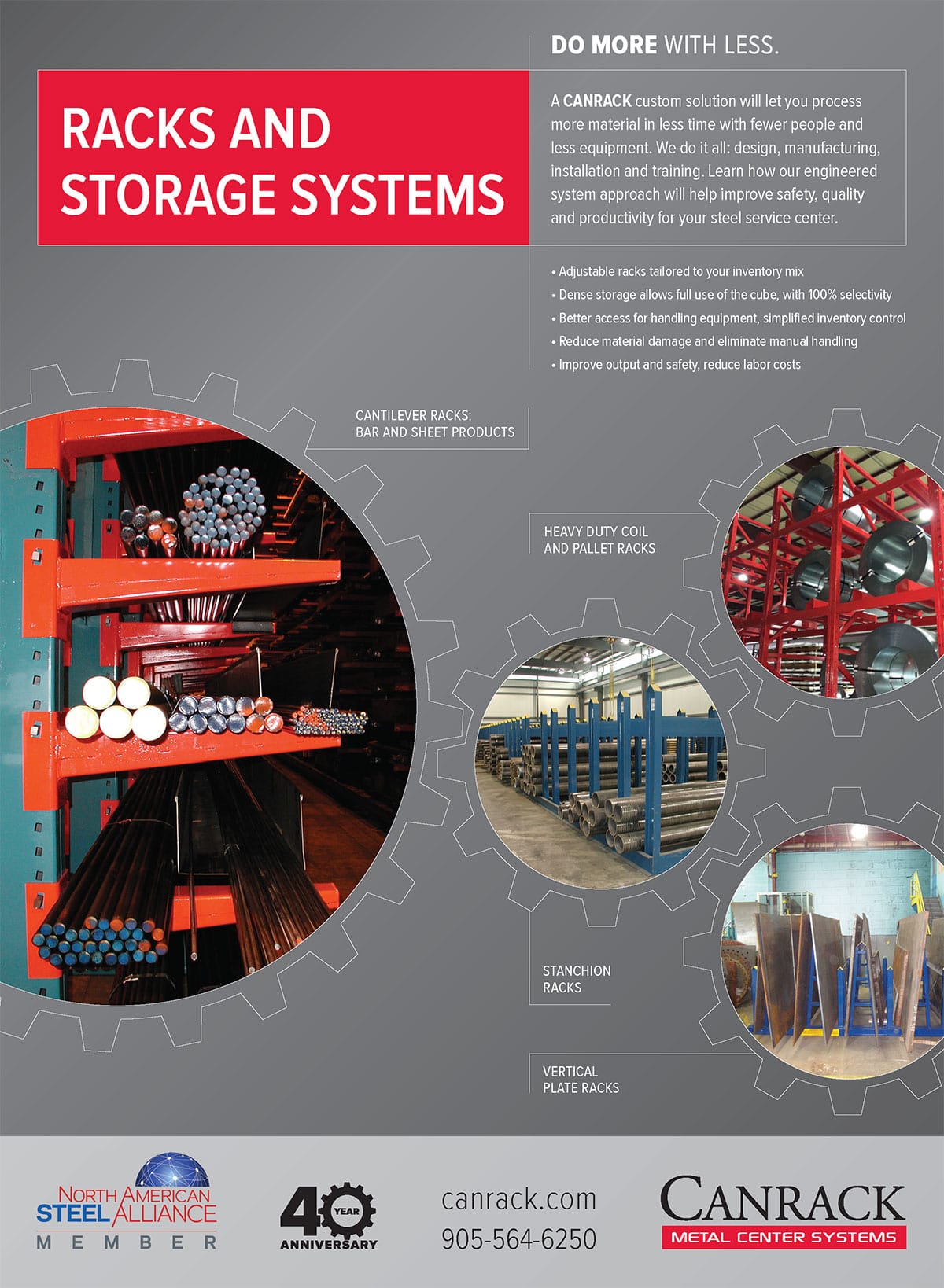

materialhandling

or every narrative, there is a beginning, middle and an end. That is how CH Steel Solutions, North Canton, Ohio, approaches a customer’s story: There’s a space, there are large, heavy objects moving around in the space and there are people working to make those objects useful.

“At a 30,000-foot level, we have a site survey procedure we use. We fill in the blanks, based on what our customer provides from the start,” says Ken Ertel. Ertel is president of a company that provides turnkey solutions for storage, racking and material handling needs at industrial distributors, many of them metal warehouses.

“Some customers give almost too much detail, and other customers have no idea where to begin,” he says. “The larger companies usually have someone on staff who has done this before. But there is always something they need that they might not have discovered.”

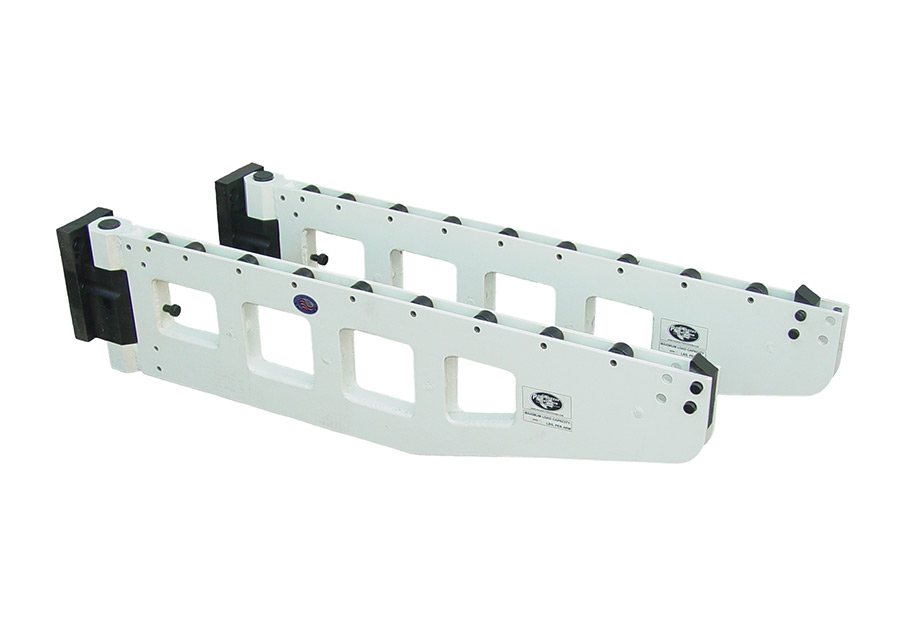

or a small business, Universal Air Suspension Co. has done some big things. The San Bernardino, California-based manufacturer invented the Aero Sport, the only air bag that can be used with a vehicle’s existing struts. Universal Air patented the design in the U.S., Australia, Japan and Canada in 2001. The company also produces an air spring several inches higher than other bags in its size class, eliminating the need for a triple bellow.

The company processes small batches of model-specific bags/brackets, compressors, controllers, tanks, valves, gauges, switches and fittings in a 15,000-square-foot facility. It can custom fit a universal air suspension on everything from a Lamborghini Gallardo to a Dodge Durango or a Datsun.

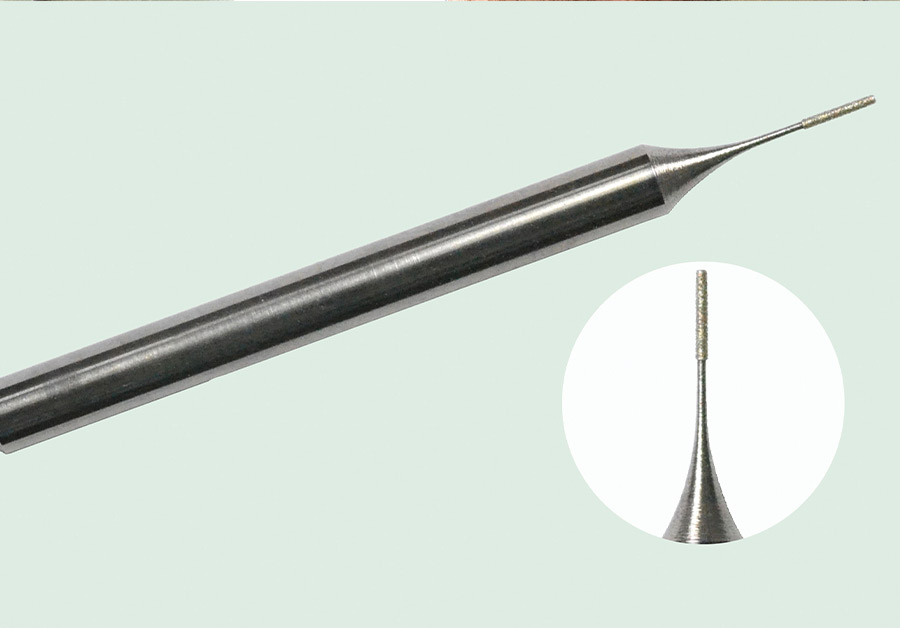

The Aero Sport is a bag-over-coil solution for lighter vehicles. These single bellow air springs are designed to slip over OEM or performance struts. The product allows customers to outfit their vehicles with air suspension without the need for hydraulics. Sourcing companies to fabricate the product according to specifications was problematic for Universal Air.

or a small business, Universal Air Suspension Co. has done some big things. The San Bernardino, California-based manufacturer invented the Aero Sport, the only air bag that can be used with a vehicle’s existing struts. Universal Air patented the design in the U.S., Australia, Japan and Canada in 2001. The company also produces an air spring several inches higher than other bags in its size class, eliminating the need for a triple bellow.

The company processes small batches of model-specific bags/brackets, compressors, controllers, tanks, valves, gauges, switches and fittings in a 15,000-square-foot facility. It can custom fit a universal air suspension on everything from a Lamborghini Gallardo to a Dodge Durango or a Datsun.

The Aero Sport is a bag-over-coil solution for lighter vehicles. These single bellow air springs are designed to slip over OEM or performance struts. The product allows customers to outfit their vehicles with air suspension without the need for hydraulics. Sourcing companies to fabricate the product according to specifications was problematic for Universal Air.

t’s difficult to find a needle in a haystack—as the “MythBusters” team proved during the show’s 2004 season, when, despite an assist from specially engineered machines, it took them a considerable amount of time to locate four needles hidden in 10 bales of hay.

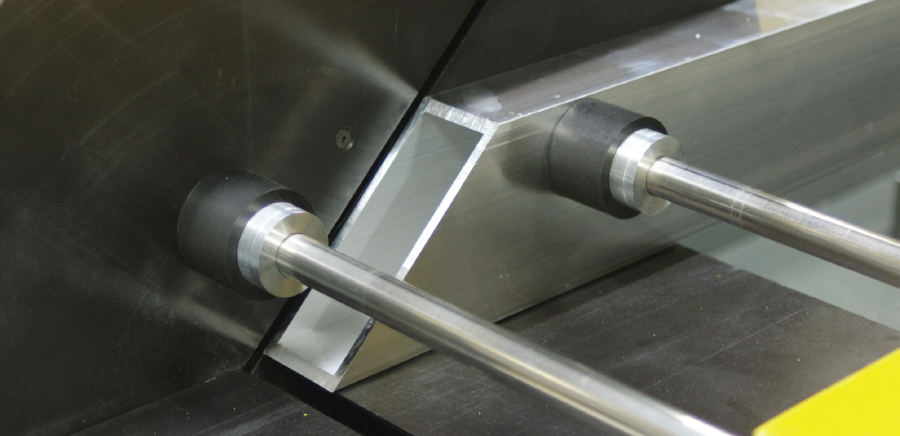

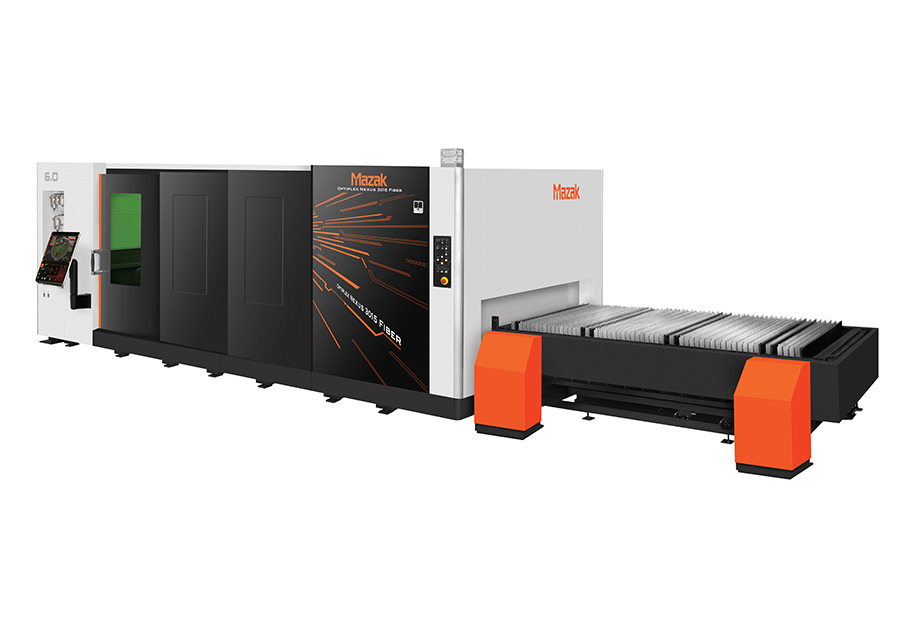

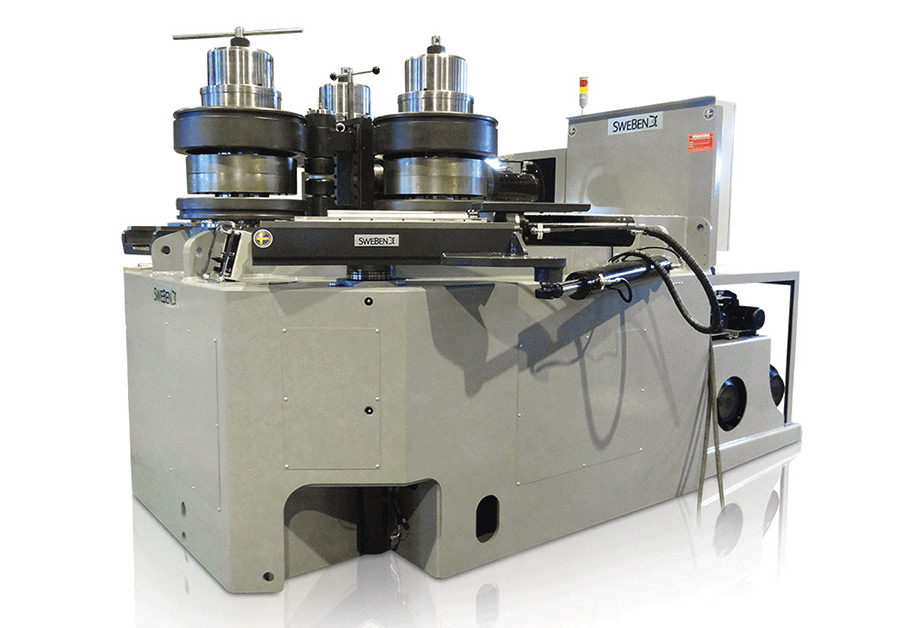

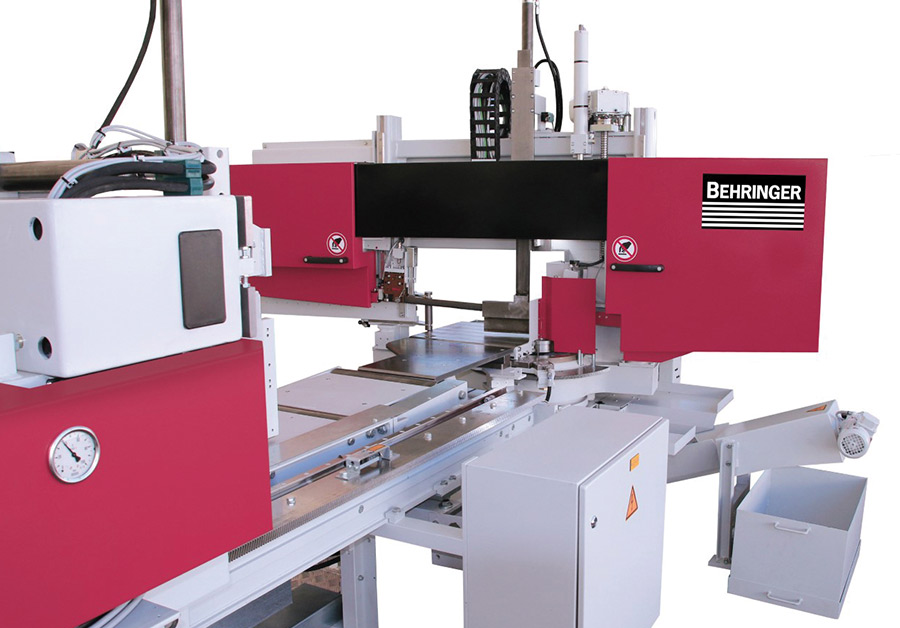

Mid-States Aluminum Corp. has its own experience searching for something that’s exceptionally challenging to find. When the Fond du Lac, Wisconsin-based company wanted to purchase a new double miter saw, it reviewed its needs and compiled a comprehensive technical machine specification, which included a durable, safe, accurate and dependable machine that used similar components as its other saws.

“We did our research and went to different trade shows to see what companies were offering. Nothing met all our criteria,” says Jeff Shoulak, process engineer.

Advertiser Index

View Index

South Tyrol, Italy

South Tyrol, Italy

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.modernmetals.com

312/654-2309, Fax: 312/654-2323

mdalexander@modernmetals.com

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@modernmetals.com

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Oklahoma, Pennsylvania, South Carolina, South Dakota, Tennessee, Texas

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@modernmetals.com

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@modernmetals.com

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@modernmetals.com

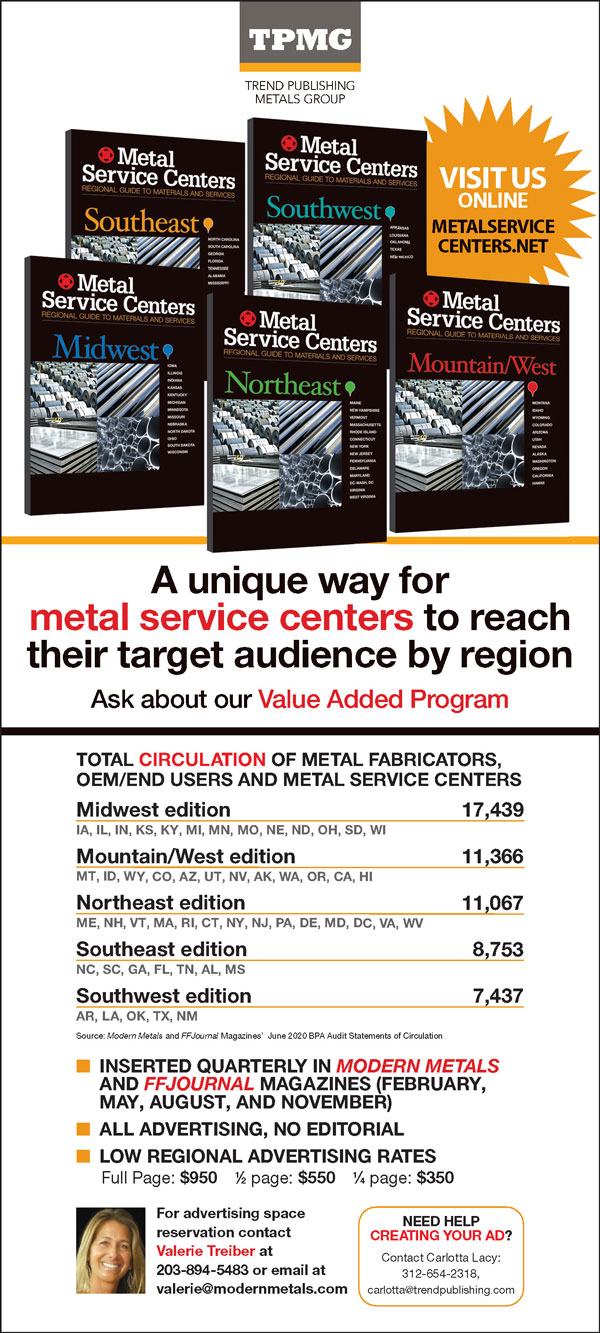

Modern Metals® (ISSN 0026-8127, USPS 357-640) November 2020, Vol. 76, No. 10 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Modern Metals® (ISSN 0026-8127, USPS 357-640) November 2020, Vol. 76, No. 10 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.