or a small business, Universal Air Suspension Co. has done some big things. The San Bernardino, California-based manufacturer invented the Aero Sport, the only air bag that can be used with a vehicle’s existing struts. Universal Air patented the design in the U.S., Australia, Japan and Canada in 2001. The company also produces an air spring several inches higher than other bags in its size class, eliminating the need for a triple bellow.

The company processes small batches of model-specific bags/brackets, compressors, controllers, tanks, valves, gauges, switches and fittings in a 15,000-square-foot facility. It can custom fit a universal air suspension on everything from a Lamborghini Gallardo to a Dodge Durango or a Datsun.

The Aero Sport is a bag-over-coil solution for lighter vehicles. These single bellow air springs are designed to slip over OEM or performance struts. The product allows customers to outfit their vehicles with air suspension without the need for hydraulics. Sourcing companies to fabricate the product according to specifications was problematic for Universal Air.

or a small business, Universal Air Suspension Co. has done some big things. The San Bernardino, California-based manufacturer invented the Aero Sport, the only air bag that can be used with a vehicle’s existing struts. Universal Air patented the design in the U.S., Australia, Japan and Canada in 2001. The company also produces an air spring several inches higher than other bags in its size class, eliminating the need for a triple bellow.

The company processes small batches of model-specific bags/brackets, compressors, controllers, tanks, valves, gauges, switches and fittings in a 15,000-square-foot facility. It can custom fit a universal air suspension on everything from a Lamborghini Gallardo to a Dodge Durango or a Datsun.

The Aero Sport is a bag-over-coil solution for lighter vehicles. These single bellow air springs are designed to slip over OEM or performance struts. The product allows customers to outfit their vehicles with air suspension without the need for hydraulics. Sourcing companies to fabricate the product according to specifications was problematic for Universal Air.

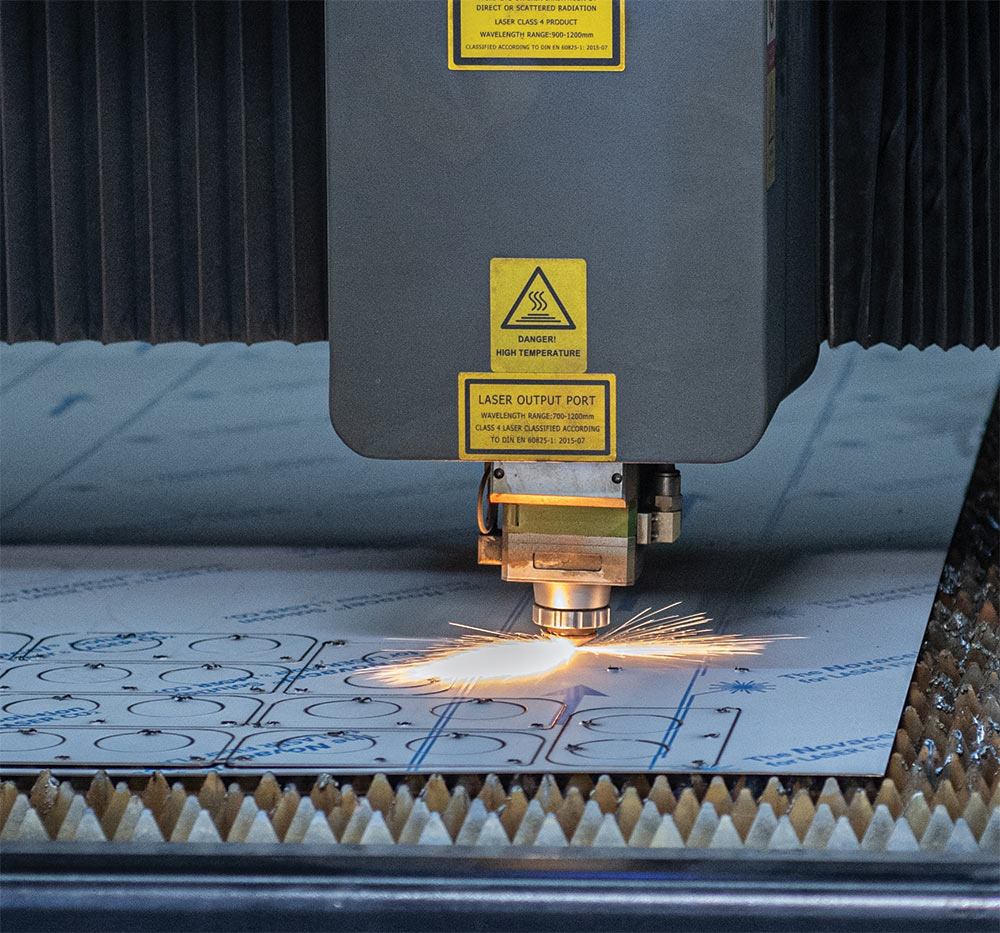

The mounting constraints prompted Universal Air to consider investing in its own fiber laser machine. Its search led it to veteran woodworking and metal cutting machine manufacturer Laguna Tools. Headquartered in Irvine, California, the 37-year-old company’s roots in woodworking equipment spurred strong growth. Laguna branched out, translating its designs into automated, industrial and classic machinery for metalworking applications.

Instead of outsourcing work we’re able to cut it all in house.

Instead of outsourcing work we’re able to cut it all in house.

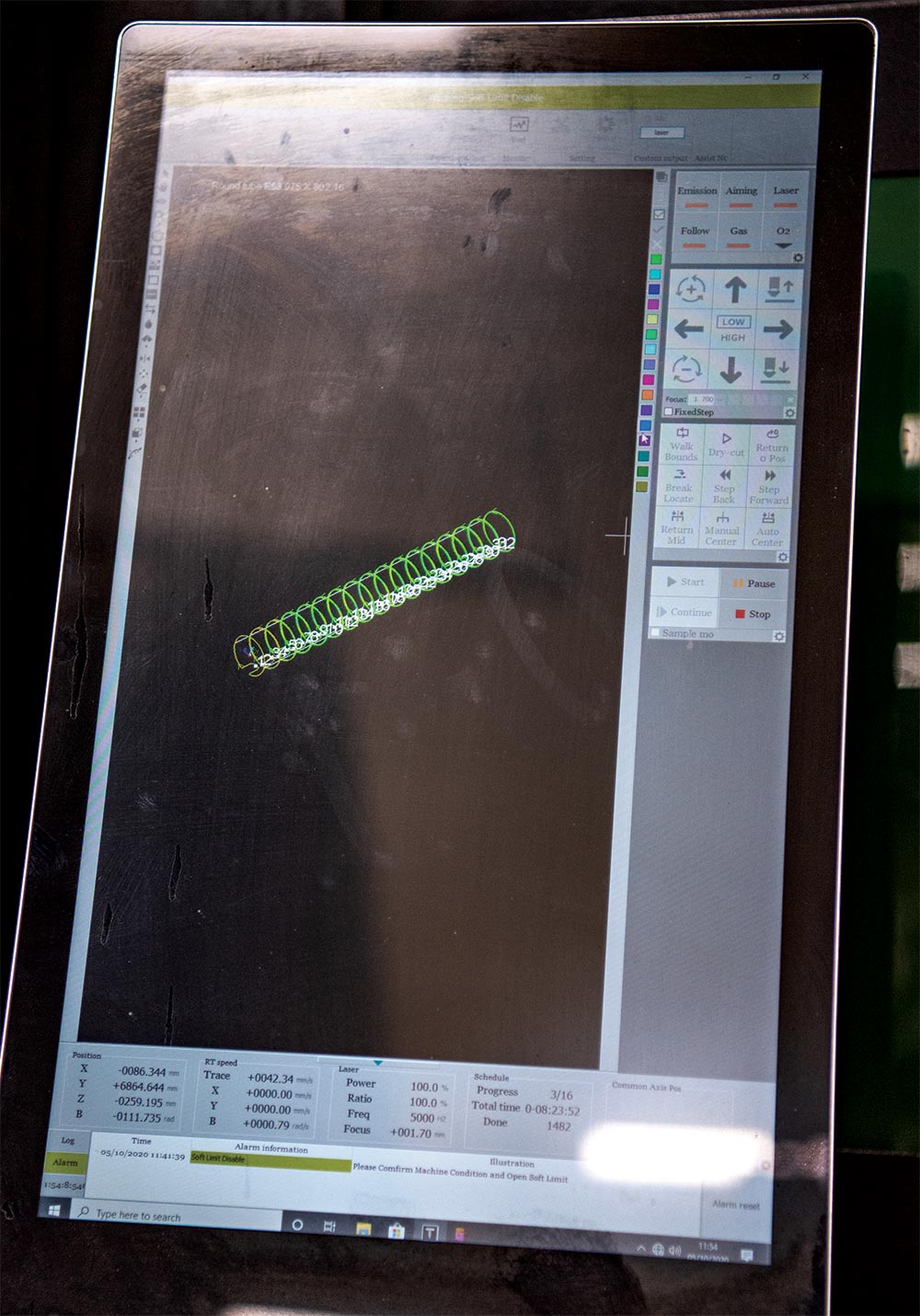

The SmartShop Laser DLP was installed in August 2020. Universal Air typically cuts 3 ⁄ 16-inch and 11-gauge steel and 16-gauge stainless sheet, along with round and rectangular tube up to 5 ⁄ 16 inch thick.

“We primarily run parts for steel bracketry on the fiber laser,” says Ratcliff. “Instead of outsourcing this work, we’re able to cut it all in house.” Previously, when developing new products, Universal Air designed the part, sent it out to be cut and faced the possibility that “when we finally got the part back, something might be off,” he says. “We have been able to reduce a two-month process to a couple hours. The fiber laser helps us make custom and one-off parts very quickly. I can’t stress how important that is. People don’t want to wait. If you are tacking on an extra six weeks, they aren’t going to wait.”

While Universal Air doesn’t consider itself a job shop, customers who visit the company and see the machine will often make requests. “We’ve sold quite a few jobs off of it that way,” he says.

Universal Air Suspension Co., San Bernardino, California, 800/864-2470, universalair.com.