We’re relentlessly committed to passionate customer service, offering versatile operations and the industries’ most expansive national footprint.

Come ride the VORTEQ wave of momentum for your coil coating needs! Let’s get started at vorteqcoil.com

Features

ow.ly/maE230rEnB1

@archinect

resident Joe Biden asked Jennifer Granholm to join his cabinet as secretary of energy, in part, because, as she said during a White House press briefing April 8, “I was the governor during a time when the auto industry was on its knees,” referring to the global recession of 2008-2009.

“I was governor when we invested to diversify Michigan’s economy to build Car 2.0, which is the electric vehicle—and the guts to that vehicle, the battery. Here we are, 12 years later, and General Motors is saying its entire fleet is going to be electrified,” said Granholm.

“Countries like China are pressing their foot on the pedal and revving up their electric engines,” she noted, supporting the idea that the federal government must continue to invest in strategies for electrification and for lowering greenhouse gas emissions nationally.

The forecast assumes steady progress on COVID-19 vaccinations will occur, allowing a gradual return to normality in major steel-consuming economies.

“Despite the disastrous impact of the pandemic on lives and livelihoods, the global steel industry was fortunate enough to end 2020 with only a minor contraction in steel demand,” comments Al Remeithi, chairman of the association’s Economics Committee. He attributed that “a surprisingly robust (9.1 percent) recovery in China while demand across the rest of the world contracted by 10 percent.

nnovation is being driven by new customers and technologies, despite potential concern over program profitability, which is changing the way automotive suppliers conduct business, according to the latest survey of members of the Original Equipment Suppliers Association (OESA), published in March.

nnovation is being driven by new customers and technologies, despite potential concern over program profitability, which is changing the way automotive suppliers conduct business, according to the latest survey of members of the Original Equipment Suppliers Association (OESA), published in March.

Asked what their biggest challenges/opportunities are as the industry prepares for a BEV future, 78 respondents noted that new customers and new technologies are driving innovation. Forty-two respondents reported that BEV programs “are changing the way we do business”; 38 companies said they are capitalizing on such programs; but 37 companies said their products are not aligned with the technology.

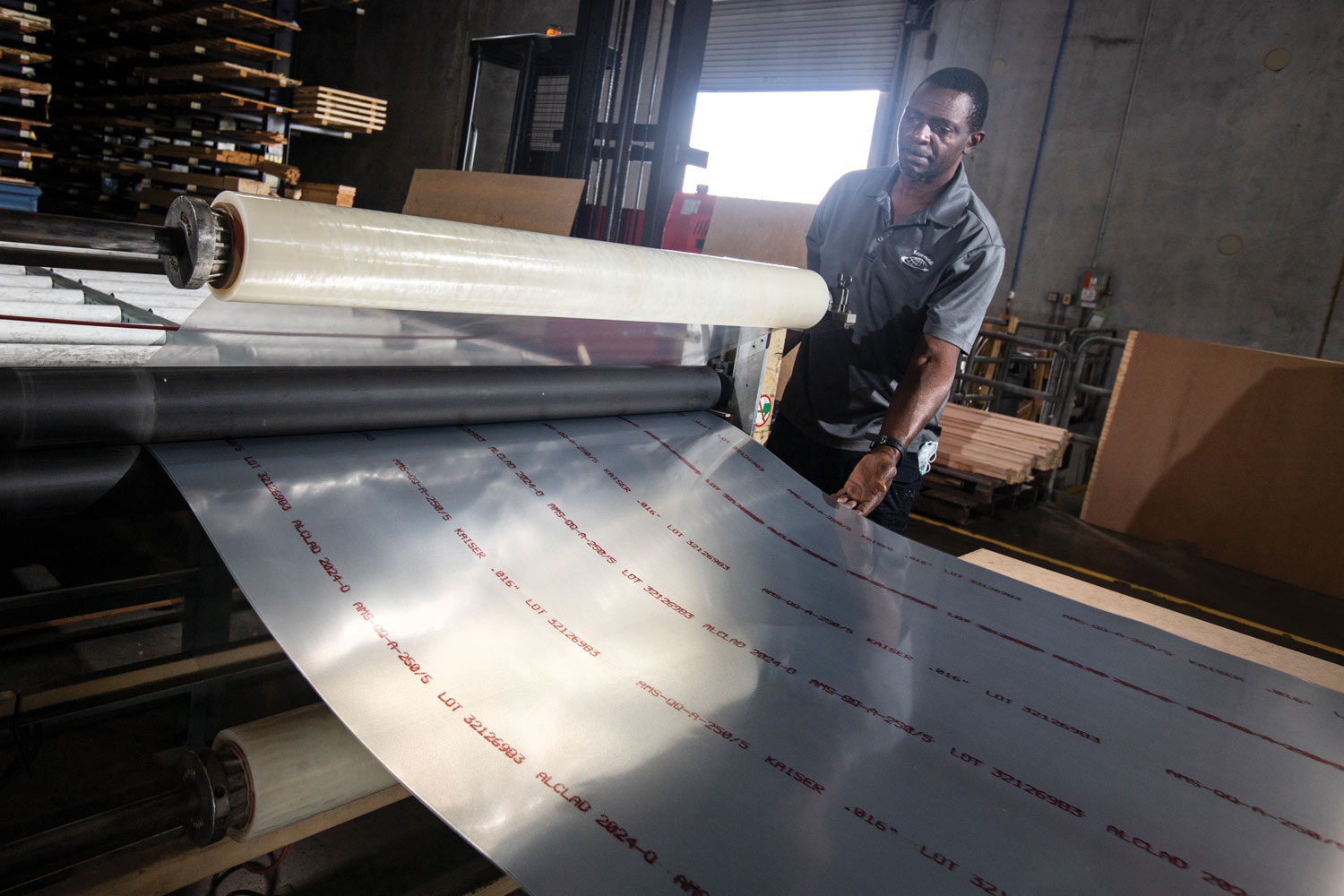

eople make all the difference in organizations. And that is especially true for companies that persevere. Future Metals is celebrating its 50th anniversary in 2021, and it would have not braved the vicissitudes of market cycles without the right people to create, maintain and grow the company.

Founders John Porfidio, president; Charles Woodard, vice president of finance; John Ferrara, vice president of sales; and Bill Menze, vice president of warehouse operations, had all worked together at Tube Distributors before becoming entrepreneurs.

Beth Erickson was hired at the tender age of 15, working part time after school as a filing clerk and telex operator. “There were no computers back then, other than the punch card data processing equipment we used for billing,” she recalls. Erickson joined the company full time upon graduating high school in 1979.

eralloy Corp. is among North America’s largest high-volume metal processors, a position it has achieved by working closely with mills, customers and technology providers. About six months ago, Feralloy started up its latest piece of technology, a Butech Bliss-built stretch-leveling cut-to-length line in Ghent, Kentucky.

Feralloy’s newest facility is located on the campus of Nucor Gallatin, which itself is in the midst of a couple key expansions. Nucor Gallatin is adding a galvanizing line. The campus will also become home to a $164 million, 250,000 tons-per-year tube mill. Nucor’s Tubular Products Group will produce hollow structural sections, mechanical steel tubing and galvanized solar torque tube at the Gallatin complex.

Before that announcement, Feralloy had already taken over an existing industrial space, which has access to rail, truck and barge (via the Ohio River).

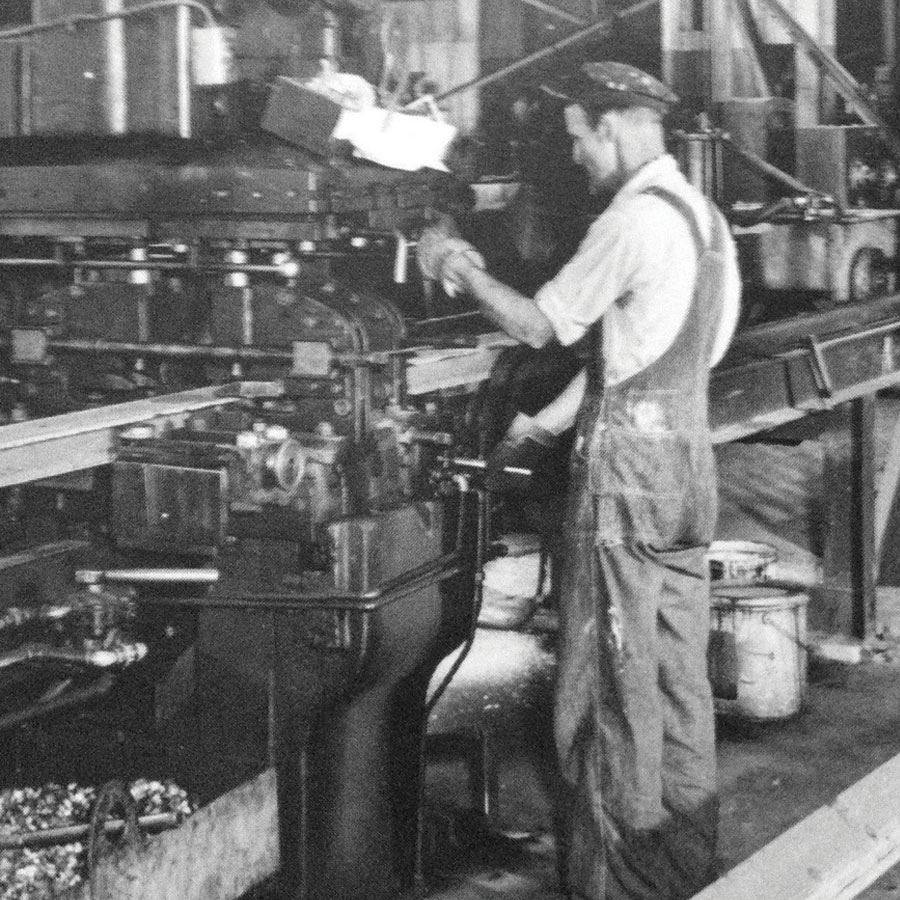

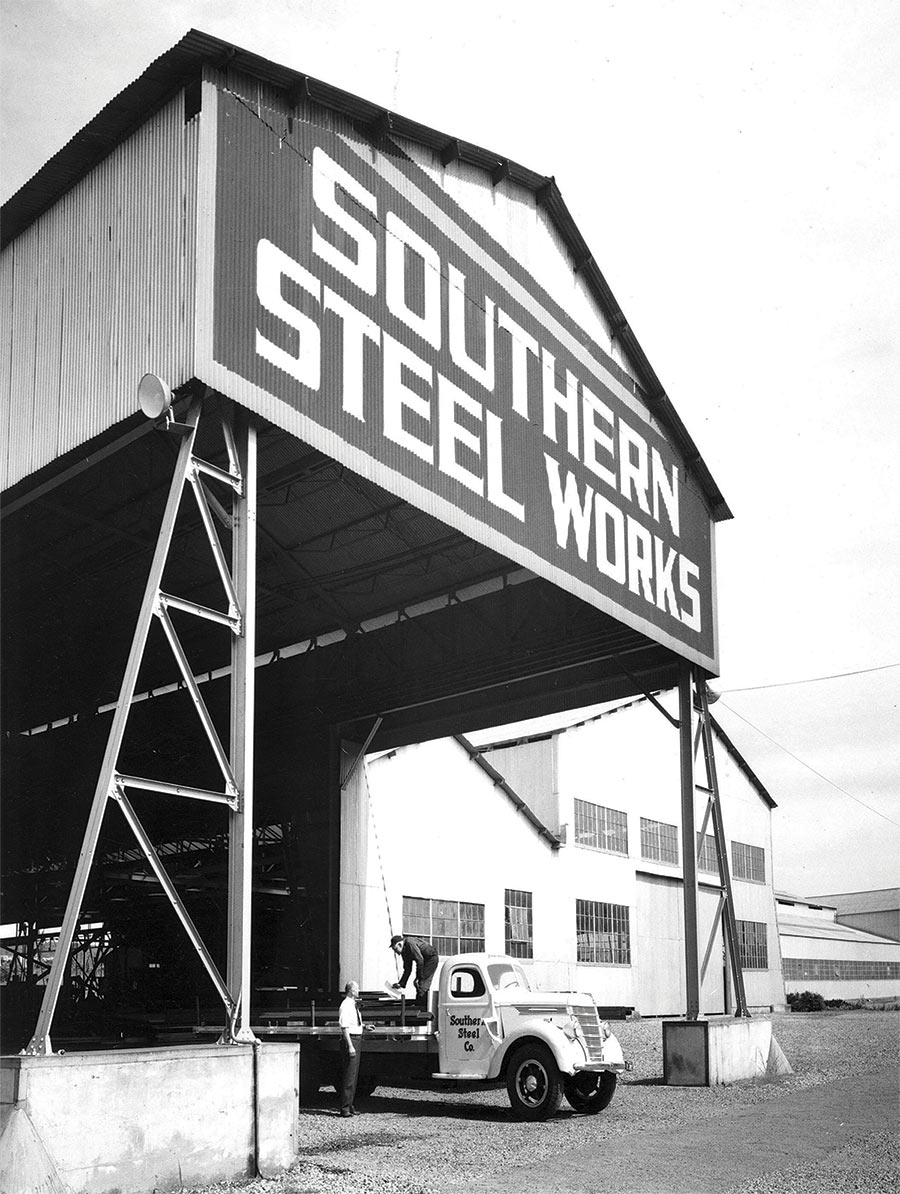

hrough a Depression, a world war, multiple recessions and other turmoil, the solid foundation of community, caring and doing the right thing has kept a service center, fabrication and manufacturing company going for a century. Modern Metals talks with the top executive and two longstanding employees about O’Neal Industries’ history and what makes it tick.

Kirkman O’Neal invested $2,000 in Southern Steel Works, a Birmingham, Alabama, fabricator of structural plate and beams, in 1921. In 1935, the company opened a service center. Kirkman O’Neal’s son, Emmet, joined the company in 1946. During World War II, Southern Steel Works produced bombs used in the Pacific theater. The company was renamed O’Neal Steel Works Co. in 1949.

“By the time of my birth in 1961, the company had been in business for 40 years; my father was 39, having been with the company nearly 15 years,” Craft O’Neal, current chairman and CEO, says.

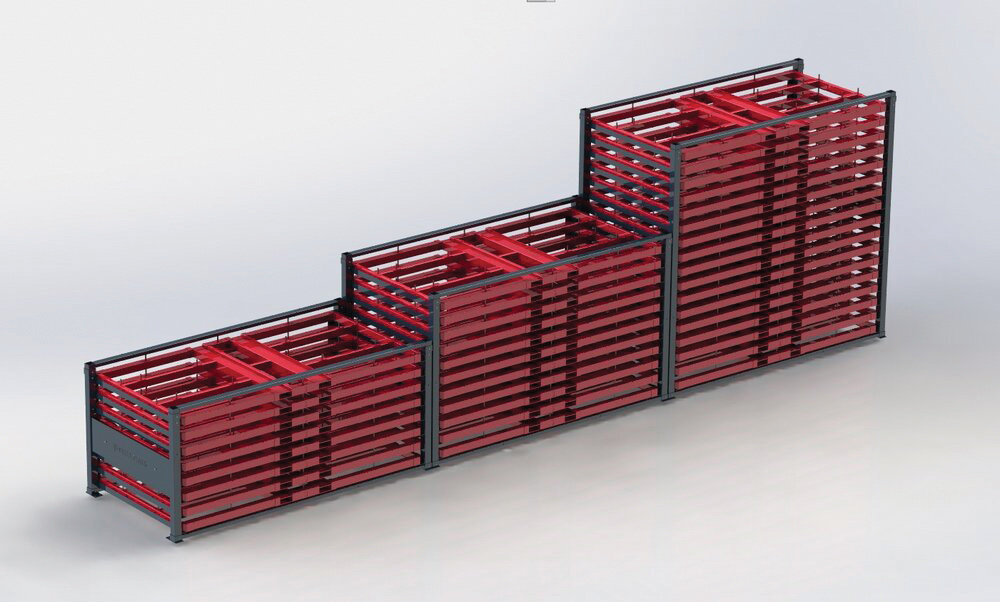

Morrison Industries, Lebanon, Tennessee, 615/547-6310, morrisonindustries.com.

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.modernmetals.com

312/654-2309, Fax: 312/654-2323

mdalexander@modernmetals.com

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@modernmetals.com

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Oklahoma, Pennsylvania, South Carolina, South Dakota, Tennessee, Texas

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@modernmetals.com

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@modernmetals.com

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@modernmetals.com

Modern Metals® (ISSN 0026-8127, USPS 357-640) May 2021, Vol. 77, No. 5 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Modern Metals® (ISSN 0026-8127, USPS 357-640) May 2021, Vol. 77, No. 5 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.