hrough a Depression, a world war, multiple recessions and other turmoil, the solid foundation of community, caring and doing the right thing has kept a service center, fabrication and manufacturing company going for a century. Modern Metals talks with the top executive and two longstanding employees about O’Neal Industries’ history and what makes it tick.

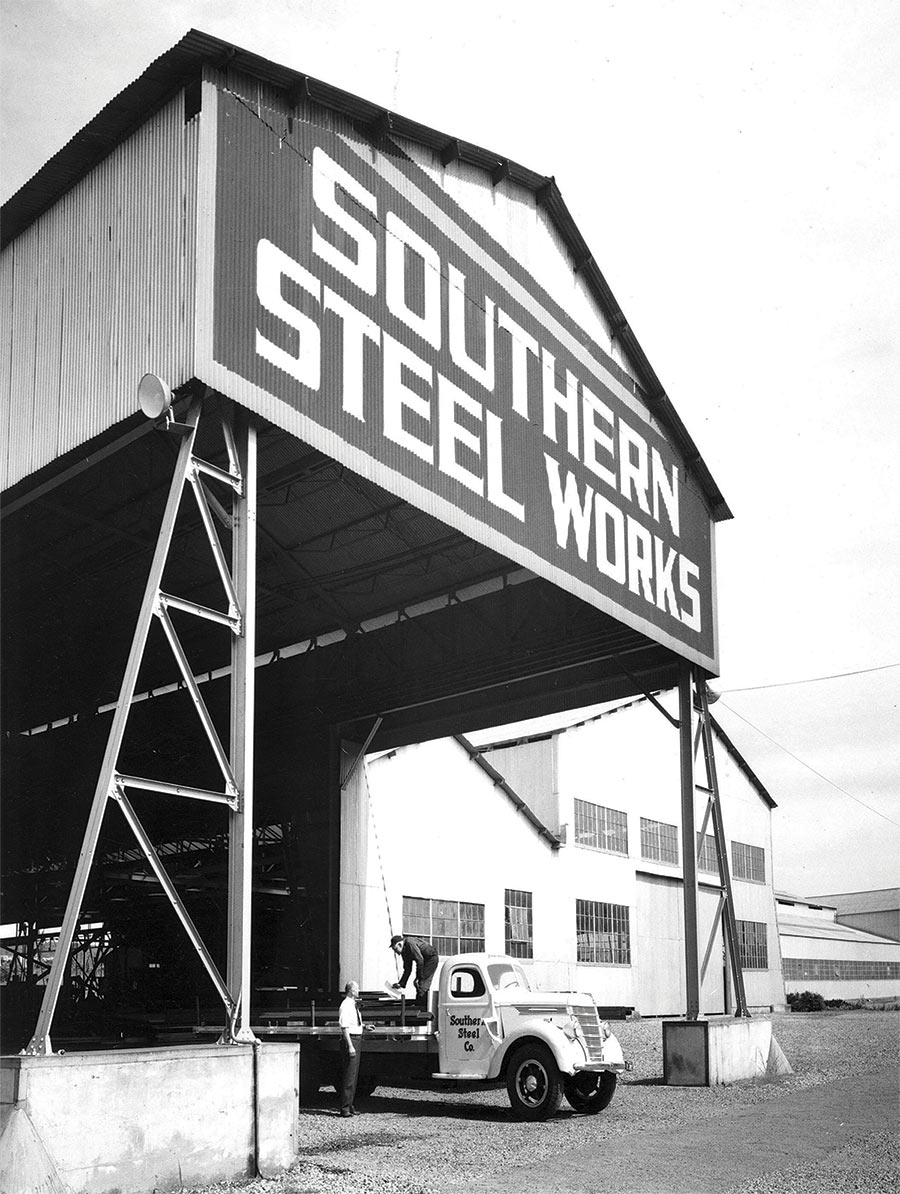

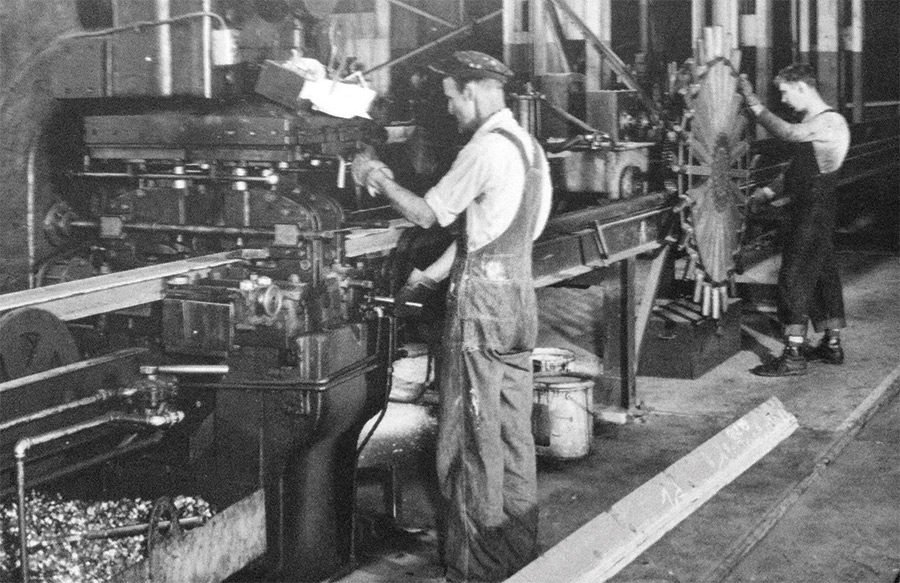

Kirkman O’Neal invested $2,000 in Southern Steel Works, a Birmingham, Alabama, fabricator of structural plate and beams, in 1921. In 1935, the company opened a service center. Kirkman O’Neal’s son, Emmet, joined the company in 1946. During World War II, Southern Steel Works produced bombs used in the Pacific theater. The company was renamed O’Neal Steel Works Co. in 1949.

“By the time of my birth in 1961, the company had been in business for 40 years; my father was 39, having been with the company nearly 15 years,” Craft O’Neal, current chairman and CEO, says.

He began working at the company during high school. “My summers in the warehouse are some of my most memorable and enjoyable times at O’Neal and provided the knowledge of warehouse operations I needed when I started in sales following college.”

That began, he says, when his father wanted to expand into Florida in the early 1960s but “he and my grandfather could not come to terms on doing that. My father would not be deterred and borrowed the money to finance the expansion himself. Fortunately, once those locations were on solid footing, the company reimbursed my father for those investments,” Craft O’Neal says.

Kirkman O’Neal, who died at age 98, remained connected with the business into his mid-90s. “His home phone had direct-dial capabilities, so he simply dialed four-digit extensions to speak with anyone within the company. He found this quite handy, and at times it was to my father’s chagrin,” O’Neal says with a laugh.

“I observed the strong relationships they developed with employees, customers and suppliers. These fundamentals are necessary for success over the long term for any business, and they and their team set the example for me and others to follow,” he says.

“I also moved into supervisory roles at a young age and, as a new manager of our Houston district, had some difficult people to manage, who tested my youth and inexperience. I put up with it for too long, and it caused heartache and performance issues. Fortunately, with the right people in place, we got on track.”

we hire very fine people who embody those values of honesty and integrity.

we hire very fine people who embody those values of honesty and integrity.

chairman and ceo

we hire very fine people who embody those values of honesty and integrity.

we hire very fine people who embody those values of honesty and integrity.

chairman and ceo

“I met my husband at work. It has been my life. I know it sounds corny but this is about the people,” Goff says. As a manager, she was taught that it is right to let employees take care of personal family issues when necessary. “I have people who report to me saying they needed to take an extra 10 minutes to take the kids to school. Our philosophy is, as long as you get the job done.”

Because of the family friendly policies, “O’Neal Steel is able to compete for talent very well,” Goff remarks.

do the right thing and everything will be OK.

do the right thing and everything will be OK.

operations manager, mobile

do the right thing and everything will be OK.

do the right thing and everything will be OK.

operations manager, mobile

At the same time, the work is very fast-paced and the company’s expansion has occurred fairly rapidly over the years. “I have seen exponential growth through acquisitions and expanding business through customers.”

Internal growth has been achieved in part through the adoption of new technologies. Because of previous development of IT capabilities, when the government declared the pandemic last spring, “we were ready to send everyone home to work.

In addition, “the guys in the shop saw immediate safety protocols put in place: masks, hand washing, social distancing. That shows concern for employees.”

Goff adds, “I wanted longevity in my career. I am here as long as they will have me.”

i met my husband at work. it has been my life. i am here as long as they will have me.

i met my husband at work. it has been my life. i am here as long as they will have me.

inside sales manager

i met my husband at work. it has been my life. i am here as long as they will have me.

i met my husband at work. it has been my life. i am here as long as they will have me.

inside sales manager

Technology throughout the company’s operations has advanced tremendously over time. “O’Neal Steel was always on the leading edge with processing equipment in the shop, such as installing a KASTO automated retrieval system, and having the best sales tools for customer use,” Burleson says. “It’s part of what make the job interesting. The company never shied away from spending money on training, either. I’ve had quite a bit of training.”

The other driver he’s witnessed through 40 years is the network’s growth. “We had 13 locations when I started and have ramped up to 20-plus. I am one of the few employees who has been at nearly all the O’Neal Steel locations.”

“Being part of a family means a lot,” he continues. “Being part of the team means a lot. This is bigger than us. And we as individuals truly have influence in directions, decisions. You will be heard. A few ideas can spur further ideas. Our leadership works hard to get us to give them input.”

Craft O’Neal confirms the guidance that all employees are given, which is based on “how my father and grandfather conducted themselves, emphasizing honesty and integrity. The reason our company has a good reputation is we hire very fine people who embody those values of honesty and integrity.

During the next 100 years, he believes the O’Neal Industries team “will continue to conduct business with the highest degree of honesty, integrity, fairness and reliability. We will preserve and build upon the greatness of our organization and, in doing so, we will continue to enhance the company’s value to our customers, employees, shareholders, suppliers and communities.”