eralloy Corp. is among North America’s largest high-volume metal processors, a position it has achieved by working closely with mills, customers and technology providers. About six months ago, Feralloy started up its latest piece of technology, a Butech Bliss-built stretch-leveling cut-to-length line in Ghent, Kentucky.

Feralloy’s newest facility is located on the campus of Nucor Gallatin, which itself is in the midst of a couple key expansions. Nucor Gallatin is adding a galvanizing line. The campus will also become home to a $164 million, 250,000 tons-per-year tube mill. Nucor’s Tubular Products Group will produce hollow structural sections, mechanical steel tubing and galvanized solar torque tube at the Gallatin complex.

Before that announcement, Feralloy had already taken over an existing industrial space, which has access to rail, truck and barge (via the Ohio River).

Rick Henke, operations manager for Feralloy, who has 33 years of experience with the company, says that the Butech Bliss line was installed last year, and the first coil rolled through it in October.

“First, we installed the Butech leveler in one of the existing bays. We then expanded that bay an additional 30,000 square feet, space that is for the storage of master coils indoors,” Henke says. “We installed a 45-ton Deshazo crane to match the capability of Nucor” in terms of master coil sizes. “So that is in support of Nucor’s expansion. Coils are shuttled over from Nucor on mill-owned railcars. We also have direct access to CSX,” which can accept coils from other steelmakers or ship outbound deliveries.

The stretch-leveling line features material handling, entry and exit equipment, along with a Synergy hydraulic roller leveler, equipped with hydraulic-powered independent entry and exit roll settings, closed-loop system to compensate for machine deflection, enhanced operator-friendly controls and a quick-change roll cartridge system.

The patented Butech Bliss stretch leveler features a 50-foot-long stretch bed and 1,900 tons of stretching force. The line can process material up to 1 inch thick by 76 inches wide and from coils that weigh up to 40 tons. The new stretch cut-to-length line will enhance Feralloy’s ability to process hot rolled, pickled, oiled and coated products. “At maximum capacity, we will be able to process 240,000 tons per year,” Henke says.

The major impetus for Feralloy’s investment decision is “the hot strip mill expansion at Nucor Gallatin, a $1.4 billion investment. Their hot-dip galvanizing line is the first that makes 1/4-inch-thick galvanized coil.”

Henke describes the advantages of the new line. “The stretch leveler has a Synergy leveler that allows you to run an entire product range without having to change out cartridges and rolls. The leveler has 1,900 tons of force. There is a 50-foot-long stretch bed. This is the biggest line that Feralloy has built, and it’s the third Butech Bliss stretch-leveler we own. The others are capable of processing material up to 3/4 inch thick.

“Our line can run at up to 150 feet per minute,” Henke says. “We have been able to stretch within 10-second cycles.”

Feralloy has long partnered with Butech Bliss. “We work together to advance the design. This one actually has eight 75-hp motors for hydraulics. It pushes 450 gallons of fluid per minute in stretching. We put variable-speed pumps on the hydraulic unit, which saves energy. It only pushes oil when it is demanded. It reduces heat and friction.”

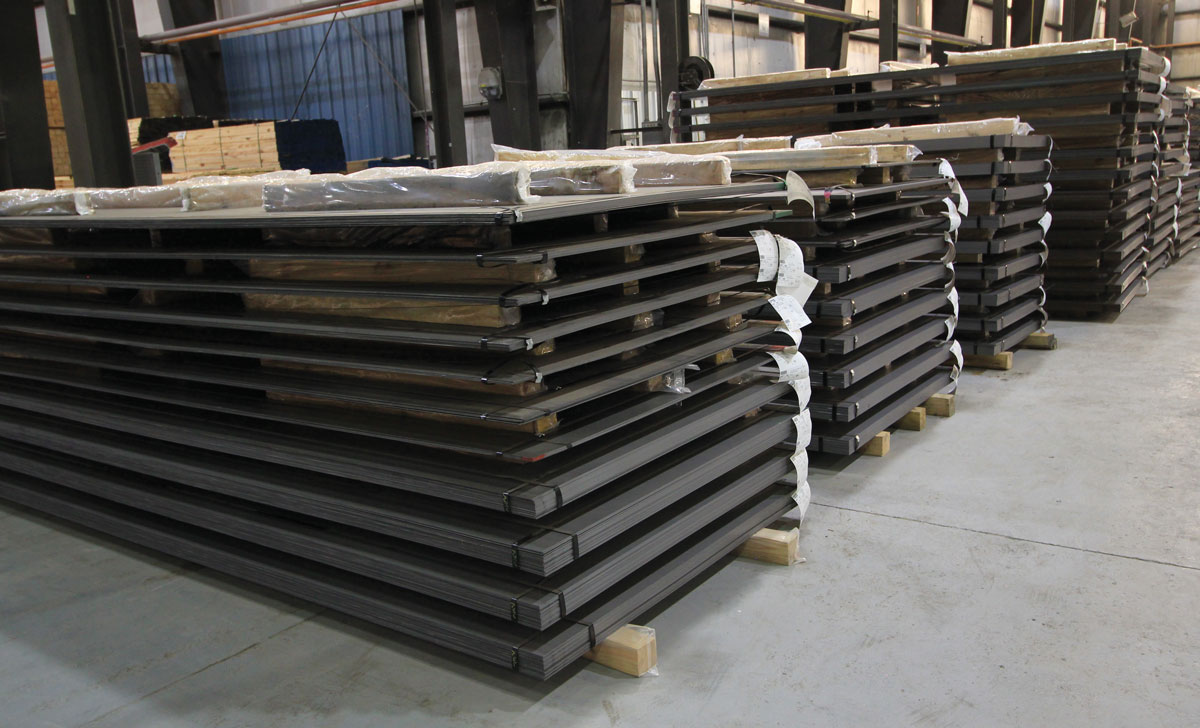

The new line also has automatic edge guide at entry and exit ends “so we can improve squareness,” says Henke. “We installed a new stacker design. The design has the control system of a rotary stacker and the functionality of a drop stacker. This has the best of both worlds. It has tampers at sides of bundles. Our bundles are nice and squared up.”

He says the line as a whole is maintenance and safety friendly.

Al Juram, sales manager for Feralloy Gallatin, says that finished coils from Feralloy end up in a wide range of applications from construction and agricultural equipment, to truck trailer and suspension systems, to service centers, general fabricators and industrial equipment.

“One of the benefits of building a new line in Kentucky is that this market is underserved,” Juram says. “There hasn’t been a coil processing line near Gallatin in 10 years. We are situated between Cleveland and Gallatin, Decatur and Chattanooga.” Regional customers will have a much more competitive freight situation in this tight transportation market.

“There are plenty of coil processors between the mills in Cleveland and Chicago in the north and Charleston, Decatur and the Arkansas mills in the South,” says Juram. “However, when focused on Gallatin, there is less capacity south of that line until you get down to Arkansas. So we can go north in any direction and not run into anyone for 150 to 200 miles.”

In other words, this new facility gives Feralloy’s trade customers and its toll processing customers “a significant geographical advantage.”

The key purpose of stretch leveling is to create memory-free sheet. “The material must stay flat throughout any process,” Juram says, including lights-out laser cutting operations. “One of the beauties of the Butech Bliss line is consistency from tip to tail of the coil. The sheet comes into a manufacturing operation flat, stays flat, and remains consistently flat throughout forming, bending and other processes. It is a superior product.”

this capability helps us expand in ultra-high strength steels.

this capability helps us expand in ultra-high strength steels.

The line was designed to mirror the capabilities of the new hot strip mill at Gallatin so it can run up to 1 inch thick by 76 inches wide.

“We think this capability helps us expand in ultra-high strength steels. The steel industry is competing against aluminum. Steel has been going lighter for years, for passenger cars, commercial and off-road vehicles, and lifting equipment. This line allows us to stretch through 1/2-inch-thick grade 100,” says Juram.

“This is a growth market for Feralloy,” confirms Henke. “We have facilities in Portage, Indiana; Charleston, South Carolina; and Decatur, Alabama. This is an opportunity to grow our business north and east, in particular.”

As of March, the Ghent plant was still in startup mode with a one-shift operation, run by 10 hourly employees. But as demand heats up through an economy rebounding from the pandemic recession, it is expected the volume will gradually expand in the coming months and years on the stretch-leveling cut-to-length line.

Feralloy Corp., Chicago, 773/380-1500, feralloy.com.