We’re relentlessly committed to passionate customer service, offering versatile operations and the industries’ most expansive national footprint.

Come ride the VORTEQ wave of momentum for your coil coating needs! Let’s get started at vorteqcoil.com

Features

ow.ly/Ouhn30rrcKI

@thedrive

vision board is a tool that visually represents goals for the future. Several major global steel producers have joined with energy companies, government agencies, academics and other partners to plan for a decarburized tomorrow. And the names involved are big: ArcelorMittal Europe, SSAB, Posco and the Colorado School of Mines, for example.

“ArcelorMittal Europe is doing a lot of work to develop a path to net zero,” or carbon-neutral steel production, CEO Aditya Mittal said in June 2020. “Steel should and can play a leading role in achieving the vision for Europe as outlined in the Green Deal.”

Researchers, backed by a U.S. Department of Energy grant, are trying to create a steel production system that combines a hydrogen-reduction reactor for ironmaking (H2DR) with electric furnace melting for steelmaking. “The integration of this H2DR combination into the U.S. supply chain would be a proof-of-concept that the steel industry is ready for decarbonization,” one of the scientists explained.

“The new program will enable Commerce and the public to better detect potential transshipment and circumvention involving aluminum products—helping to ensure that domestic producers can compete on a level playing field,” commented Secretary of Commerce Wilbur Ross.

Under AIM, importers will be required to obtain a free, automatic import license before they import aluminum products. To obtain the import license, companies must report the volume, value, country of origin, country of most recent cast, and certain other information. The licensing requirement became effective on Jan. 25.

ydrogen is the most abundant chemical substance in the universe, constituting roughly 75 percent of all matter that humans encounter. Also, hydrogen is a clean fuel that, when consumed in a fuel cell, produces only water. Hydrogen can be produced from a variety of domestic resources, such as natural gas, nuclear power, biomass, and renewable power like solar and wind. These qualities make it an attractive fuel option for transportation and electricity generation applications and, eventually, for industrial-scale metals production.

Hydrogen has become the new buzzword in raw metal manufacturing. Over the past few months, several major global steel producers have joined with energy companies and other partners to plot their way to a decarburized future.

In August 2020, Stockholm-based SSAB, with its partners—iron ore producer LKAB and energy company Vattenfall—started up Hybrit, a pilot plant that manufactures sponge iron.

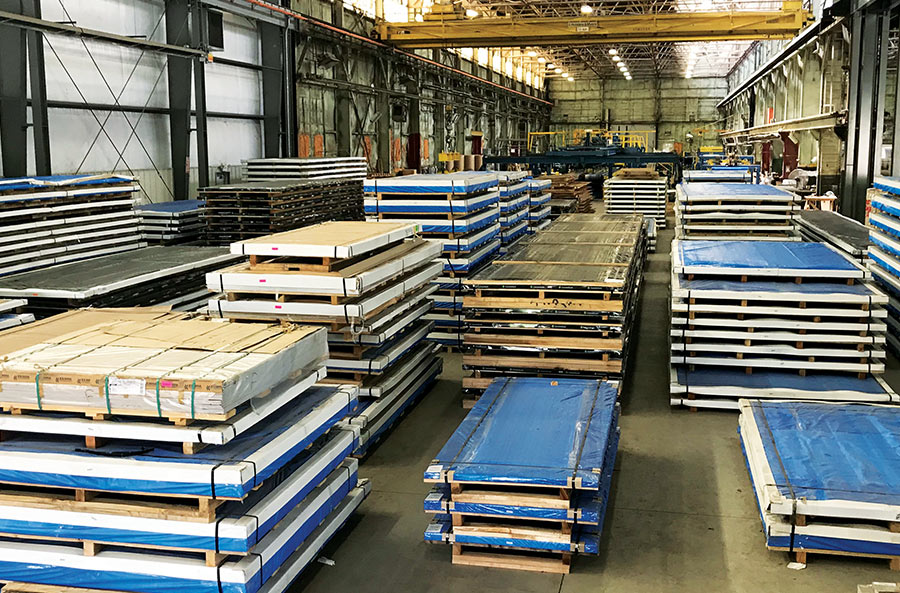

he cyclical nature of America’s economy can take a toll on metal processors and distributors, especially when they are ill prepared for a dramatic change in fortunes. Prices plunge, and warehouses are left with too much material that needs to be written down. Or a pandemic stops work at thousands of construction sites for months at a time, which may mean the silencing of structural tube cutting machines.

Ways to push back against the inevitable ups and downs include diversifying the customer base, so that no one customer canceling orders will cause a giant loss, and diversifying one’s processing capabilities. Invest in bending equipment in the Southeast or a laser cutting system in the Great Plains, or both.

These are the strategies employed by Boyd Metals, which helped the company bring work inside that was once outsourced, thereby saving money for Boyd and Boyd’s customers. Because so many pieces of equipment are new, the company is also landing new business with clients that demand tight tolerances and shorter lead times.

& prevent

& prevent

lan your work for today and every day. Then work your plan.” This advice from the late British Prime Minister Margaret Thatcher distills the importance of having guidelines to clarify the competing priorities that tug at each one of us every day. Without a strategy, routine tasks like preventive maintenance (PM) can be neglected. However, it’s a lot easier in the long run to take steps to keep equipment in smooth working order because unplanned downtime and expensive costs are never part of the plan.

Mike Robinson, customer service supervisor at OMAX Corp., says that “every one” of the Kent, Washington-based waterjet manufacturer’s customers who have instituted a PM program for their equipment “has found some measure of good results.”

He cites one customer that already had a PM program in place but then “hired a new maintenance manager who incorporated better tracking of consumption to help him predict the maintenance needs, which allowed him to schedule time on the machines before they went down. They almost never were waiting on parts for a down machine. Rather, they had already ordered them and had them on hand before the failure. This drastically reduced machine downtime and saved a lot of money.” Robinson notes that this same maintenance manager took another step to save money and time: he rebuilt the swivels—a part that allows the waterjet cutting nozzle to travel across the table surface—in his office. “When one needed to be rebuilt, he would swap it with the one on his desk,” and prepare the other part for the next time, which means the machine never runs with a leak.

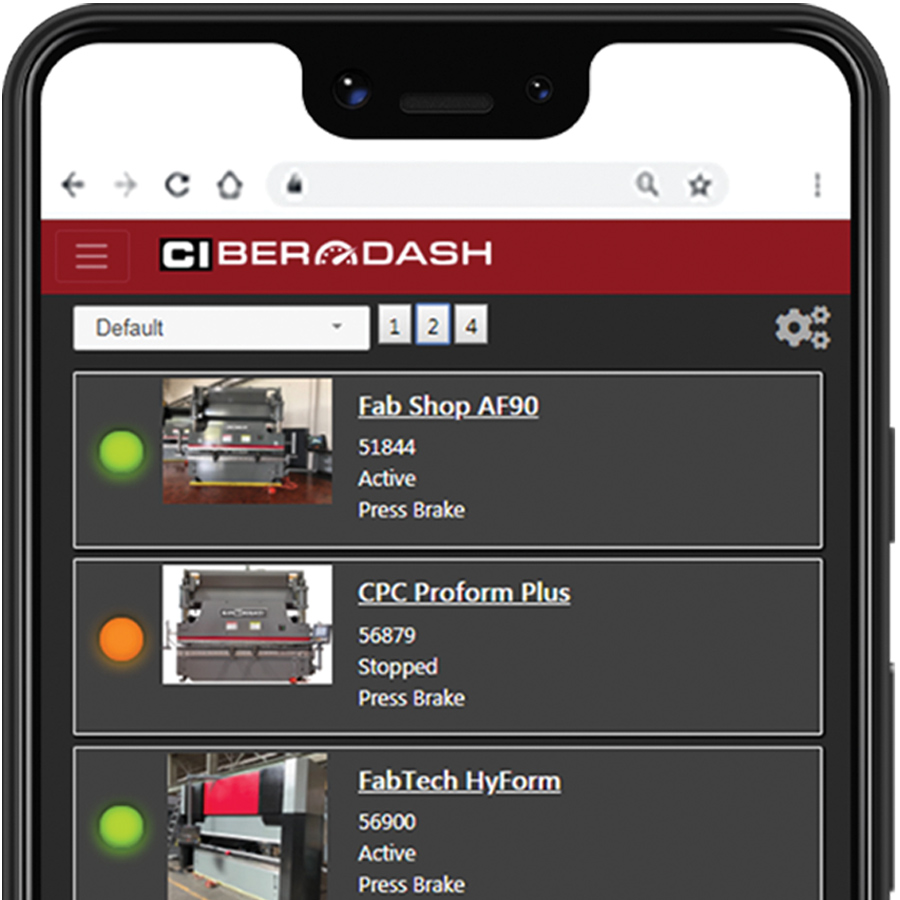

he smart factory trend continues to gain speed, especially in the way that software and sensors work together to provide real-time, actionable information on what’s happening with metalforming equipment.

Cincinnati Inc., which designs and sells press brakes and shears, laser cutting and additive manufacturing systems, is among those machine builders that have embraced and advanced Industry 4.0 on behalf of their North American clients.

CIberDash, developed over the past two-plus years, allows real-time monitoring and daily logging of production data from Cincinnati equipment by connecting machines to the cloud through ethernet or a cellular transmitter.

CIberDash gives companies using Cincinnati products the ability to monitor performance remotely from a dashboard. On a smartphone, desktop or tablet, the digital tool displays each machine’s information and program details as well as the current 24-hour status of production. CIberDash also creates daily log files for each laser cutting table and press brake, and users can extract more than 50 separate categories from the logs, from product name to machine strokes to cycle time.

Technical Sales Manager,

Magswitch Technology Inc.

ow more than ever, magnets are ubiquitous in our everyday lives. They are transforming the e-mobility and vehicle industry with use in electric motors, allowing high-speed transit with maglev trains, and are now providing a cool factor in the smartphone accessory industry.

Based in Lafayette, Colorado, with Australian roots, Magswitch Technology uses magnets to create a more efficient, safer and more connected world. Magswitch was founded as a result of a fascination with magnets and their ability to change the way things are done. The company has held onto that mantra by recently changing the game in the automotive industry. In the past two years, it has developed and commercialized a family of Industry 4.0 electric magnetic grippers, allowing up to a 27 percent reduction in total investment and a 25 percent reduction in floor space required for vehicle manufacturing.

Magswitch’s standard product offering fulfills most customers’ performance needs. However, there are customers that can and should use a truly integrated system. Early on, Magswitch recognized that integration of its technology into third-party products would allow it to generate new opportunities. This realization quickly turned into action, and since then, the company has partnered with dozens of companies to co-develop product portfolios.

Advertiser Index

View Index

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.modernmetals.com

312/654-2309, Fax: 312/654-2323

mdalexander@modernmetals.com

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@modernmetals.com

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Oklahoma, Pennsylvania, South Carolina, South Dakota, Tennessee, Texas

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@modernmetals.com

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@modernmetals.com

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

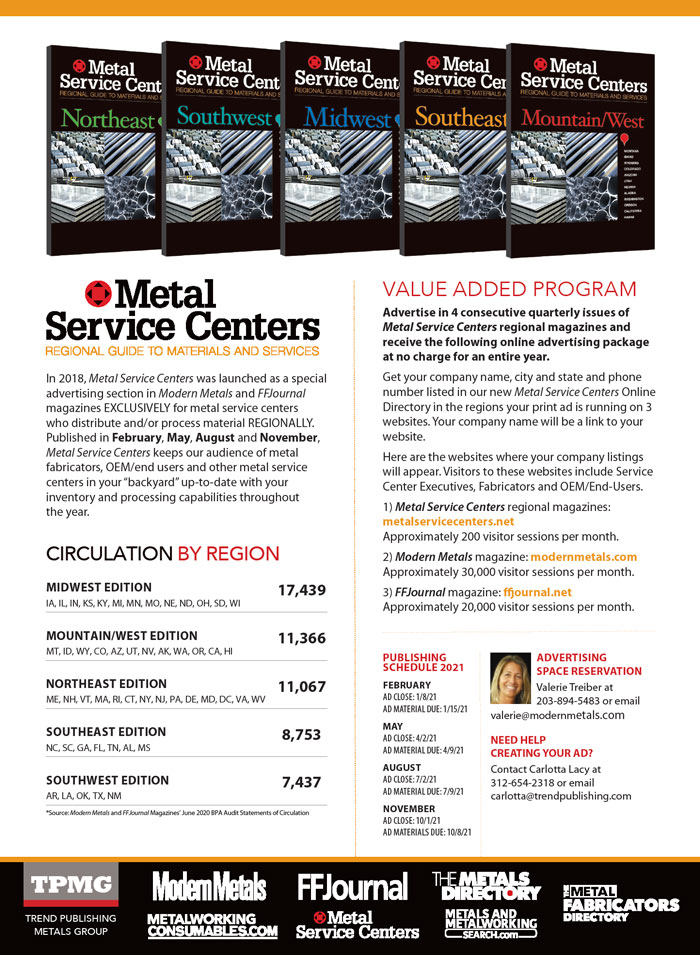

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@modernmetals.com

Modern Metals® (ISSN 0026-8127, USPS 357-640) February 2021, Vol. 77, No. 2 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2021 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Modern Metals® (ISSN 0026-8127, USPS 357-640) February 2021, Vol. 77, No. 2 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2021 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.