he cyclical nature of America’s economy can take a toll on metal processors and distributors, especially when they are ill prepared for a dramatic change in fortunes. Prices plunge, and warehouses are left with too much material that needs to be written down. Or a pandemic stops work at thousands of construction sites for months at a time, which may mean the silencing of structural tube cutting machines.

Ways to push back against the inevitable ups and downs include diversifying the customer base, so that no one customer canceling orders will cause a giant loss, and diversifying one’s processing capabilities. Invest in bending equipment in the Southeast or a laser cutting system in the Great Plains, or both.

These are the strategies employed by Boyd Metals, which helped the company bring work inside that was once outsourced, thereby saving money for Boyd and Boyd’s customers. Because so many pieces of equipment are new, the company is also landing new business with clients that demand tight tolerances and shorter lead times.

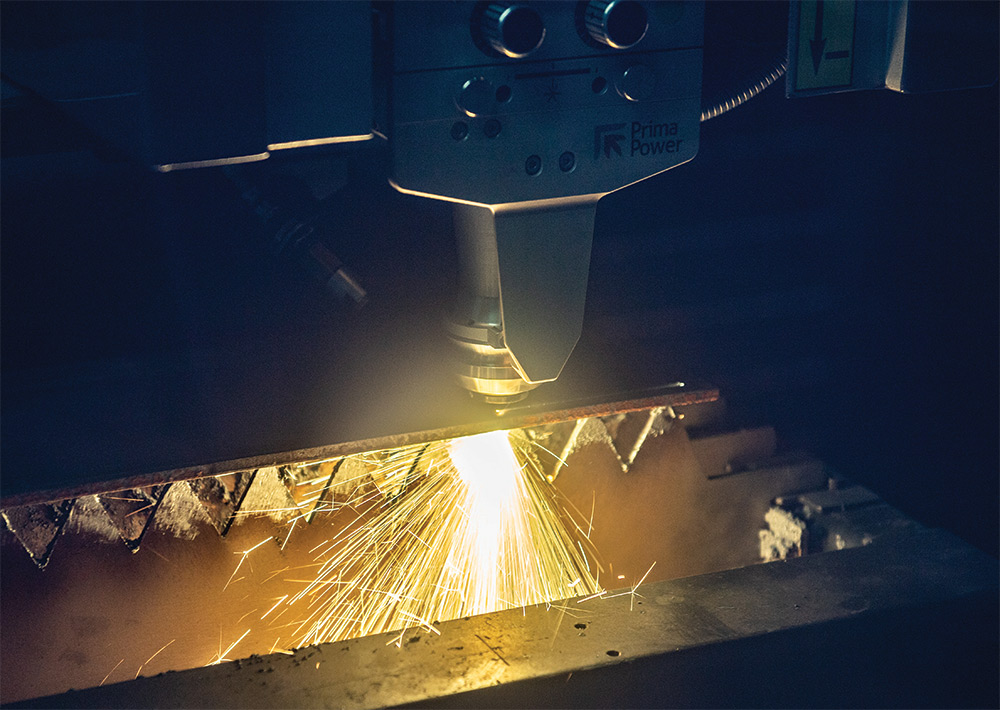

Audie Dennis, vice president and general manager of the Joplin service center, says that three of Boyd’s five locations (Fort Smith, Joplin and Oklahoma City) purchased three Prima Power Laser Genius 20240 model, 6000-watt laser cutting systems in late 2019 and 2020.

Joplin also has one of the three Prima Power lasers that Boyd Metals purchased. The table capacities on all three lasers are 80 by 160 inches. “In Joplin’s case, both the laser and the press brake have allowed us to bring in house an existing base of work that prior to this we have had to outsource,” he says.

the customers love the quality. it’s another arrow in our quiver.

the customers love the quality. it’s another arrow in our quiver.

“The customers love the quality,” Schultz says. “It’s better than our regular high-definition plasma cutter. It’s able to hold much tighter tolerances, particularly on thicker plate over 1/2 inch. Customers are tickled with it. It’s another arrow in our quiver.”

Also on the energy front, “there is a lot of bid work for solar projects,” says Testa, predicting, “We are going to see solar farms as part of the infrastructure stimulus plan [legislators] are talking about.”

“The laser is meeting our expectations so we are able to fill a niche. There are a lot of laser machines in our market but we are able to help with overflow. We are fulfilling customer needs and putting out a good product.”

Harvey’s team also installed is a semiautomatic 25-inch vertical saw with miter capability. “We are doing a lot for customers that are supporting transportation and logistics. Amazon, UPS and FedEx all need warehouse infrastructure like conveyors for package handling. We are also doing general construction and metal buildings,” says Harvey.

“In Oklahoma City,” he continues, “we repurposed our guys who run CNC machines to run high-definition plasma tables and now they also run the laser. We had an existing employee with experience with press brakes who helped us. We do send our people out for training, and they pick it up really quickly.

“One thing we have done differently is send key salespeople to training with the actual equipment operators,” Dennis notes. “They know virtually everything about the capabilities of the machine and when they talk to customers, they have that knowledge. We want our salespeople as knowledgeable about the customers’ own business as they are.”

“We do kitting for some customers. Before, we outsourced that and lead times became long,” he says. “Now, we are able to do that in house and reduce costs across the board and shorten lead times. One of the kits we assemble has 70 to 80 parts in it, and we even build special crates to protect the parts from damage. It’s value added and cements our relationship with that customer.”

“As the costs of human capital rise, automation is the answer. The Compaq server on the laser is a small step in that direction. We are actively looking at ways to automate both in processing and in our overall warehouse operations in the coming years.”