Technical Sales Manager,

Magswitch Technology Inc.

ow more than ever, magnets are ubiquitous in our everyday lives. They are transforming the e-mobility and vehicle industry with use in electric motors, allowing high-speed transit with maglev trains, and are now providing a cool factor in the smartphone accessory industry.

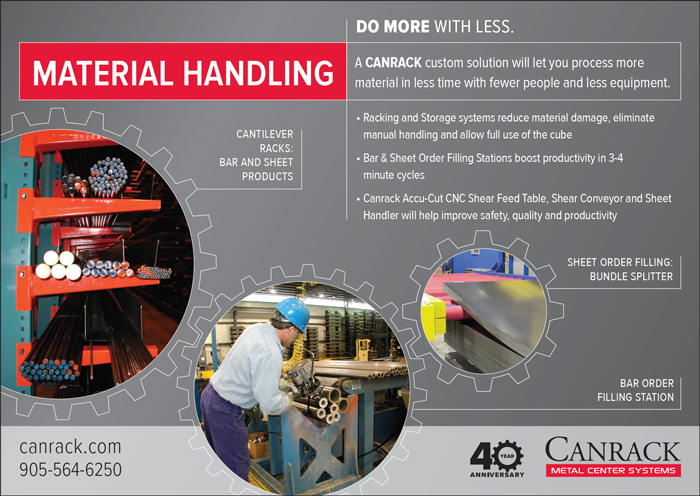

Based in Lafayette, Colorado, with Australian roots, Magswitch Technology uses magnets to create a more efficient, safer and more connected world. Magswitch was founded as a result of a fascination with magnets and their ability to change the way things are done. The company has held onto that mantra by recently changing the game in the automotive industry. In the past two years, it has developed and commercialized a family of Industry 4.0 electric magnetic grippers, allowing up to a 27 percent reduction in total investment and a 25 percent reduction in floor space required for vehicle manufacturing.

Magswitch’s standard product offering fulfills most customers’ performance needs. However, there are customers that can and should use a truly integrated system. Early on, Magswitch recognized that integration of its technology into third-party products would allow it to generate new opportunities. This realization quickly turned into action, and since then, the company has partnered with dozens of companies to co-develop product portfolios.

There are customers that can and should use a truly integrated system.

There are customers that can and should use a truly integrated system.

The mission is to deliver a complete solution and specialized product delivery process to every customer. Magswitch helps customers to engineer and design a switchable magnet for their products. It provides industrial design, ISO-9001 manufacturing, third-party logistics, product, social media marketing and other services. A completely integrated, Magswitch-built solution will remain tied to the customer’s company’s mission, brand and quality requirements.

A recent collaboration with a U.S.-based ergonomic drum and roll handling equipment manufacturer provided a unique challenge for Magswitch.

Drums, one of the most common containers for shipping bulk cargo, are traditionally handled using gripping equipment that either grabs the top of the drum or wraps around the cylinder. This is problematic for handling because drums are typically stacked in close quarters, leaving little to no room for a mechanical gripper.

Like most companies that Magswitch works with, this customer wanted to break free from the old way of doing things and pursue a better way, using a single-sided magnetic gripping solution. This solution would require Magswitch to develop a new remote-controlled electric actuation system that would allow forklift operators to activate and deactivate the magnets without leaving the forklift. Through considered engineering and assiduous collaboration, Magswitch developed, and made available, a solution that it began to market last year.

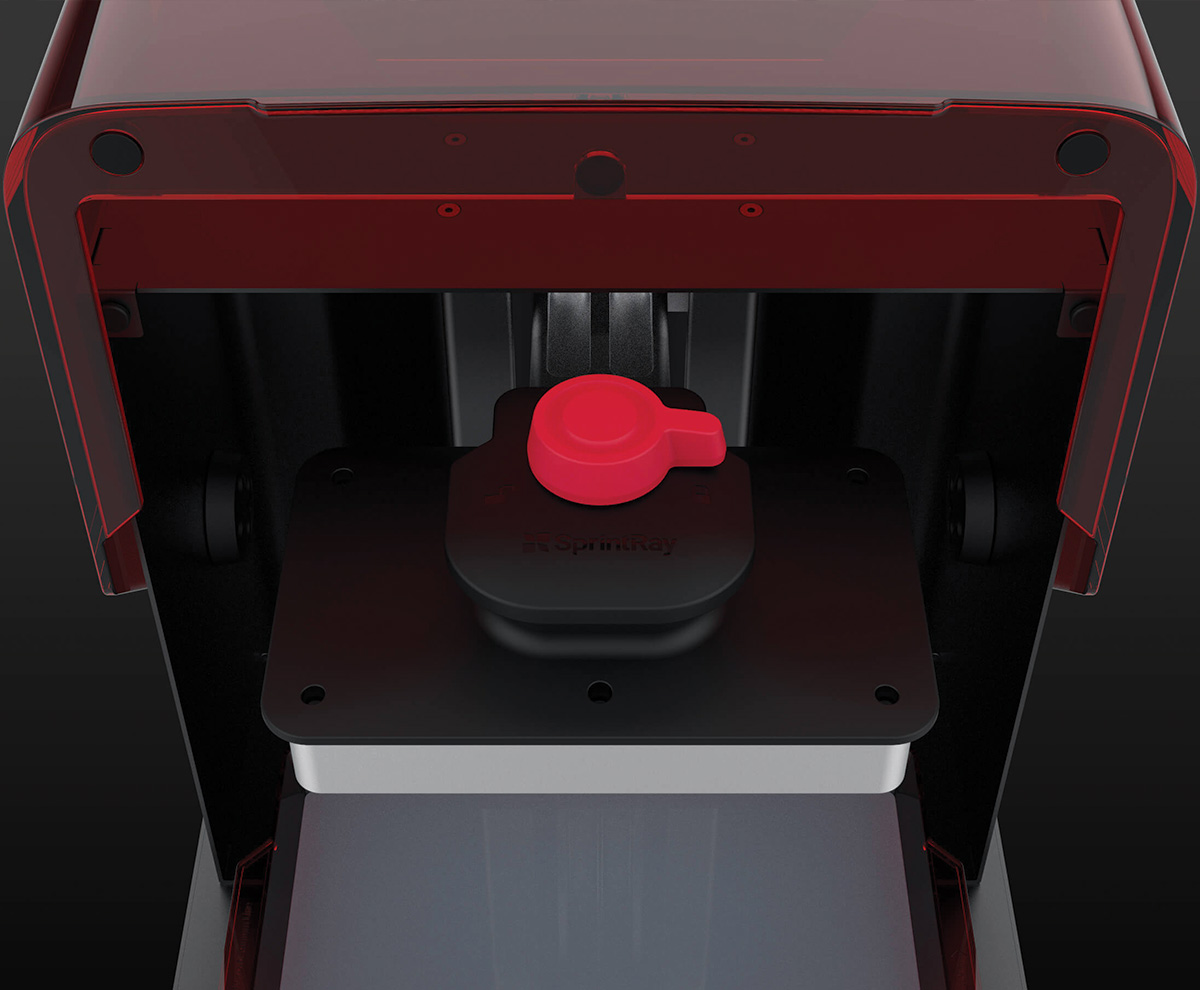

Another recent collaboration with a digital dentistry customer, SprintRay, required Magswitch to customize its Magswitch MagJig 150. The customization involved smoothing out the actuation cycle and completely integrating the magnet, making it almost hidden. The custom switchable magnet secures the printing platform while the printing process occurs, replacing a manual process that previously required twice the effort.

Now in 2021, as Magswitch’s electric actuation technology evolved, the company is collaborating on a new electric Magswitch unit that will integrate directly into the 3D printer’s controls and user interface.

As Magswitch continues to develop technology and know-how, it adds performance features that increase customer satisfaction, efficiency and safety. While it’s the core technology (switchable magnets that turn completely off) that helps set the company apart, it also customizes new technology for specific applications. For example, the vendor engineers custom magnetic circuits that are optimized on the exact material grade and thickness of major applications. The latest automotive application has a focus field on materials thinner than 1 millimeter because that is what has become most common in the industry.

Magswitch’s engineers think bigger than magnets; they want to disrupt and improve the whole process, so they have become more focused on upstream phases from manufacturing and assembly like design and end-of-arm-tools. In the same way, the team seeks to learn about new industries and applications, focusing on improving and automating processes. The greatest commitment is to making the world a more efficient and safer place.