Features

henever I start worrying about the demand picture for mass quantities of metals products, I turn to the U.S. Department of Defense page that shows contract awards and contract extensions. There is a great deal of business transacted with our military and with our allies throughout the world.

In addition, many service centers and others throughout the metals supply chain are qualified to work with the Defense Logistics Agency. Suppliers vetted and approved by the DLA provide a vast array of materials for trucks and airplanes, tanks and barracks, warehouses and weapons, barges and medical equipment.

A: It’s no mystery that the steel industry workforce is getting older. When I describe it as “older,” I am referring to the people, the talent and the decision-makers. Steel companies are still making many critical decisions based on tribal knowledge, gut feel or pure historical experience, so it is absolutely critical that companies within the steel industry begin to diversify their knowledge base, develop talent, and begin the process of succession planning and career development to ensure that their associates’ knowledge and experience doesn’t dwindle with each retirement.

The American Iron and Steel Institute’s directors elected John Brett, president and CEO of ArcelorMittal USA, as board chairman for a one-year term. Brett has been serving as interim chairman since mid-March after Roger Newport, CEO of AK Steel Holdings Inc., retired. AISI also elected Kevin Dempsey as interim president and CEO to succeed Thomas J. Gibson. Dempsey has served as AISI’s senior vice president for public policy and general counsel since 2009.

Zekelman Industries promoted Tom Muth, a 30-year steel industry veteran, to executive vice president and COO of the newly created Tubular Products Division. The business includes Wheatland Tube, Western Tube, Atlas Tube, Picoma and Sharon Tube. Jeff Cole was promoted to president of Atlas Tube. He joined the company in 1993 and served most recently as vice president of operations, overseeing HSS plants.

Andrew Rose, president of Worthington Industries, Columbus, Ohio, will also take on the role of CEO effective Sept. 1, succeeding long-time chairman and CEO John P. McConnell, who will remain with the company as executive chairman.

TAB Industries LLC, Reading, Pennsylvania, 610/921-0012, tabwrapper.com.

Shoots

here seem to be but three ways for a nation to acquire wealth. The first is by war, as the Romans did, in plundering their conquered neighbors. This is robbery. The second by commerce, which is generally cheating. The third by agriculture, the only honest way, wherein man receives a real increase of the seed thrown into the ground, in a kind of continual miracle.”

here’s a song in the Broadway musical Jesus Christ Superstar called “What’s the Buzz,” which might remind some folks of the news-gathering business. John Packard, who had a long career in the steel industry, was always attuned to the buzz of industry talk and, for the past dozen years, has paid close attention to the information he heard, analyzed it and amplified it through a well-received newsletter. Packard is the founder of Steel Market Update.

Packard studied to become a teacher, graduated, went home, then asked his college sweetheart to come visit him, with the hope of proposing marriage. She broke up with him instead. “That put me at a crossroads,” he recalls.

erviacero Comercial is part of a network of service center and processing facilities across the manufacturing-rich regions of Mexico. Owned and operated by the Zermeño family, the company has expanded its reach and capabilities over the past 54 years.

The Serviacero parent group comprises 24 service centers in the states of Guanajuato, Nuevo León, Queretaro, Jalisco, San Luis Potosi, Michoacán, Aguascalientes, Hidalgo, Sonora and Mexico City.

Its services include laser-quality cut to length for light- and heavy-gauge material, slitting, pickling and oiling; roll forming for wall and deck panels and roll-formed profiles; tubular manufacturing and processing; steel grating manufacturing and fabrication; laser/plasma cutting, bending, machining, welding and painting; and the design and manufacturing of steel racks and containers.

ervice centers need the right software tools to navigate in a fast-paced, rapidly fluctuating climate. Rapid growth coupled with increased restrictions and regulations means managers must be vigilant about overseeing the ins and outs of their business. They also must be able to access information quickly to make decisions in real time.

“Communication is even more important now with so many people working remotely,” says Paul Parsons, vice president of sales and marketing for 4GL Solutions. The Stouffville, Ontario-based company writes ERP software tailored to the needs of service centers. Last year, 4GL released Task Manager, a product that covers the breadth of a client’s activities and connects managers with personnel from the shop floor to the top floor. Task Manager also supports social distancing by minimizing or eliminating the need for face-to-face interaction among employees, Parsons adds.

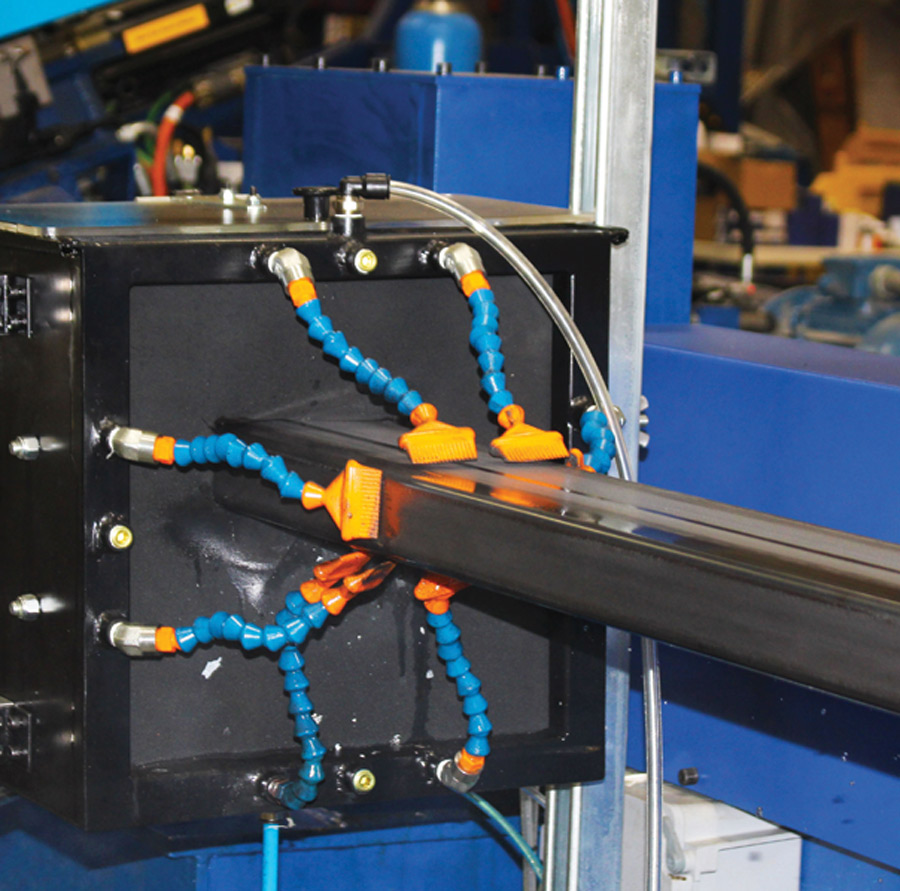

n investment in knowledge pays the best interest,” said inventor and founding father Benjamin Franklin. As the experienced team at Toledo, Ohio-based Heidtman Steel embarks on its newest investment—a tube mill joint venture located at its Erie, Michigan, campus, just north of Toledo—it relies on knowledge as a driving force toward success.

During its 65-plus years in business, Heidtman has been a part of several industry firsts, including building the largest pickling line of any service center in the United States, being one of the five founding investors in Steel Dynamics, and was the first service center to market thin slab mill products to the automotive industry.

“John Bates Sr. not only has always been able to recognize an opportunity but also has the guts to do something about it. That’s a big part of how he grew this company,” says Tim Berra, Heidtman’s president and CEO.

modification

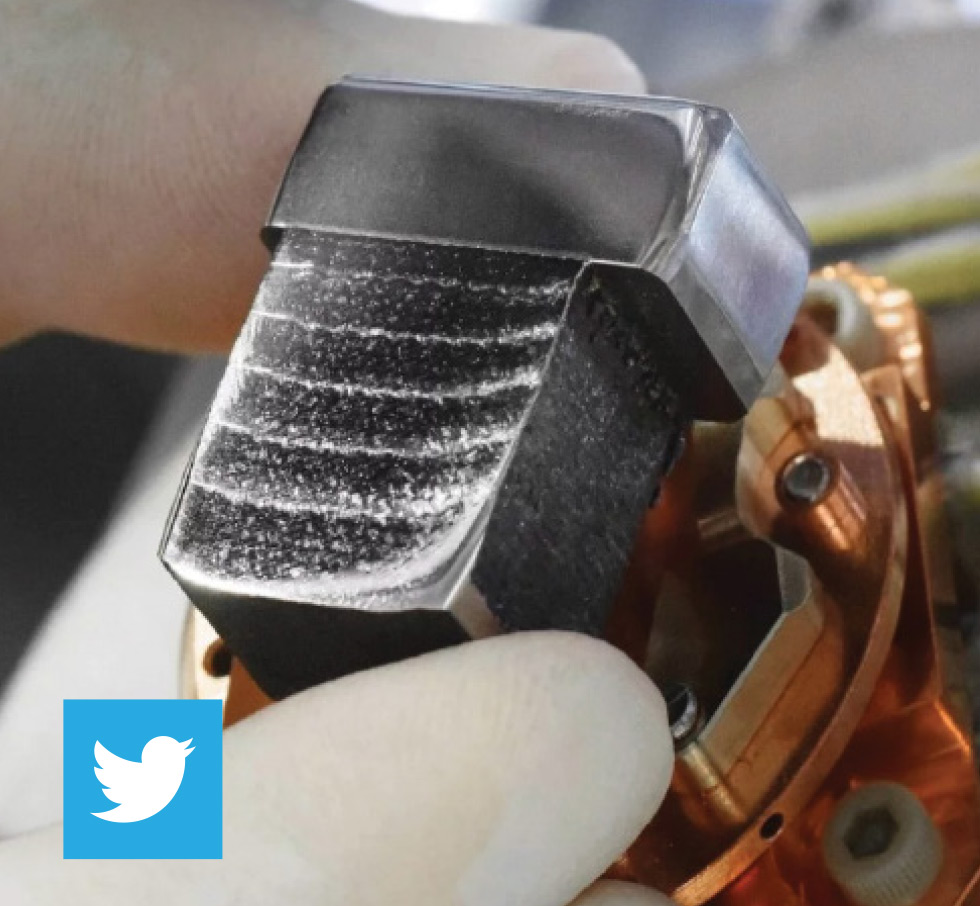

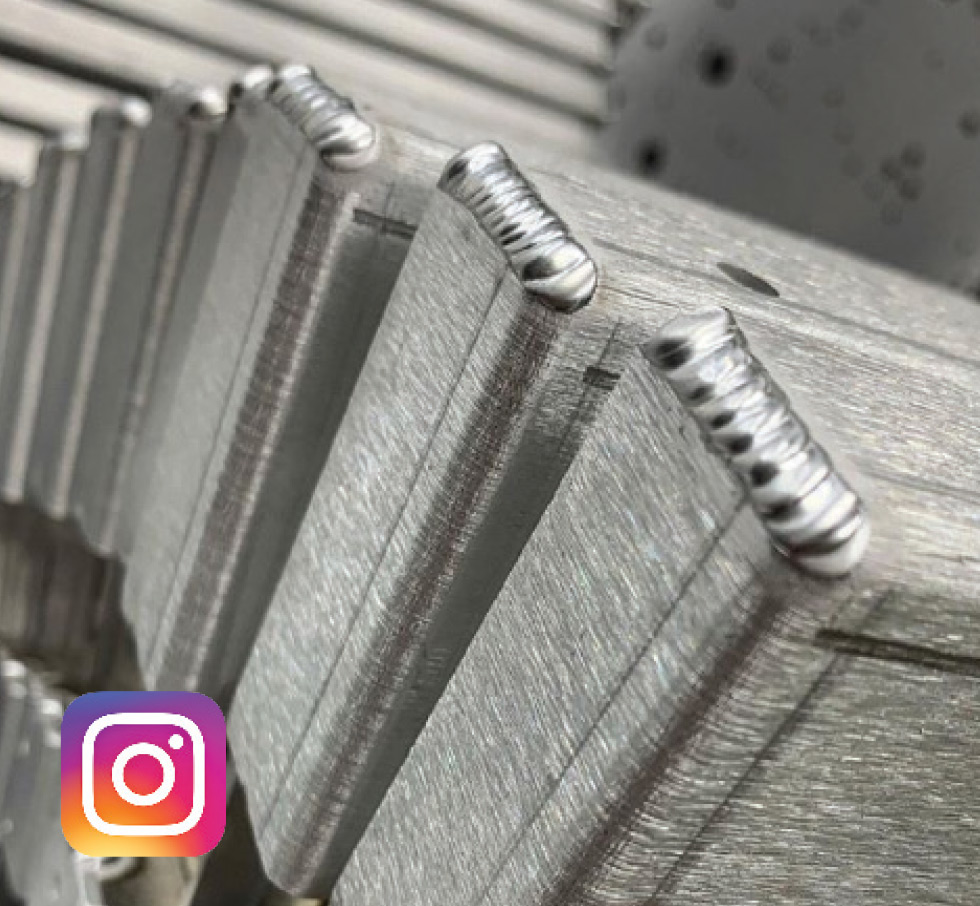

rcanum Alloys Inc., a technology-driven company, has created an altered process flow that meets current needs and anticipates future commercial applications. Arcanum Alloys’ proprietary process, called spatially optimized diffusion alloy (SODA), is altering steel processing to serve innovators that demand better performance.

Originally founded in 2011, this Silicon Valley startup moved to Kentwood, Michigan, to expand its team and bring its technology to commercial scale. Arcanum Alloys’ SODA process was developed on 1-square-inch panels in the laboratory but has since scaled to the production of 20-ton coils.

“Our process is disrupting current metallurgical methods and steel manufacturing as we know it. This revolutionary technology possesses the solution for products across many evolving industries,” says Arcanum Alloys’ founder and CEO, Dan Bullard.

Advertiser Index

View Index

partingshot

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.modernmetals.com

312/654-2309, Fax: 312/654-2323

mdalexander@modernmetals.com

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@modernmetals.com

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Oklahoma, Pennsylvania, South Carolina, South Dakota, Tennessee, Texas

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@modernmetals.com

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@modernmetals.com

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@modernmetals.com

Modern Metals® (ISSN 0026-8127, USPS 357-640) August 2020, Vol. 76, No. 7 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Modern Metals® (ISSN 0026-8127, USPS 357-640) August 2020, Vol. 76, No. 7 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.