We’re relentlessly committed to passionate customer service, offering versatile operations and the industries’ most expansive national footprint.

Come ride the VORTEQ wave of momentum for your coil coating needs! Let’s get started at vorteqcoil.com

Features

cannot know war or anything like it, not up close. I have been spared. Sometimes, only poetry can distill the sense of loss, and the pain those who survive war might feel. Here are excerpts from “Phantom Noise,” by poet Brian Turner, who is known for his writing about the Iraq war.

There is this ringing hum

This bullet-borne language, ringing shell-fall ….

This wing-beat of rotors and tanks broken

Bodies ringing in steel

Kunz: Looking at the history of B+S, the roots of our company lie in the narrow field of precision slitting lines and slitting machines for longitudinal slitting. Therefore, the expansion of the product range and the increase of our vertical range of manufacture were essential to today’s success. Special mention should be made of the integration of Schnutz GmbH, a traditional German company for high-performance levelers, and DAA DELTA Technik GmbH, our expert for automation technology. This enables us to supply our customers with complex systems from a single source. It also simplifies the logistical processes and enables individual production of machines and plants.

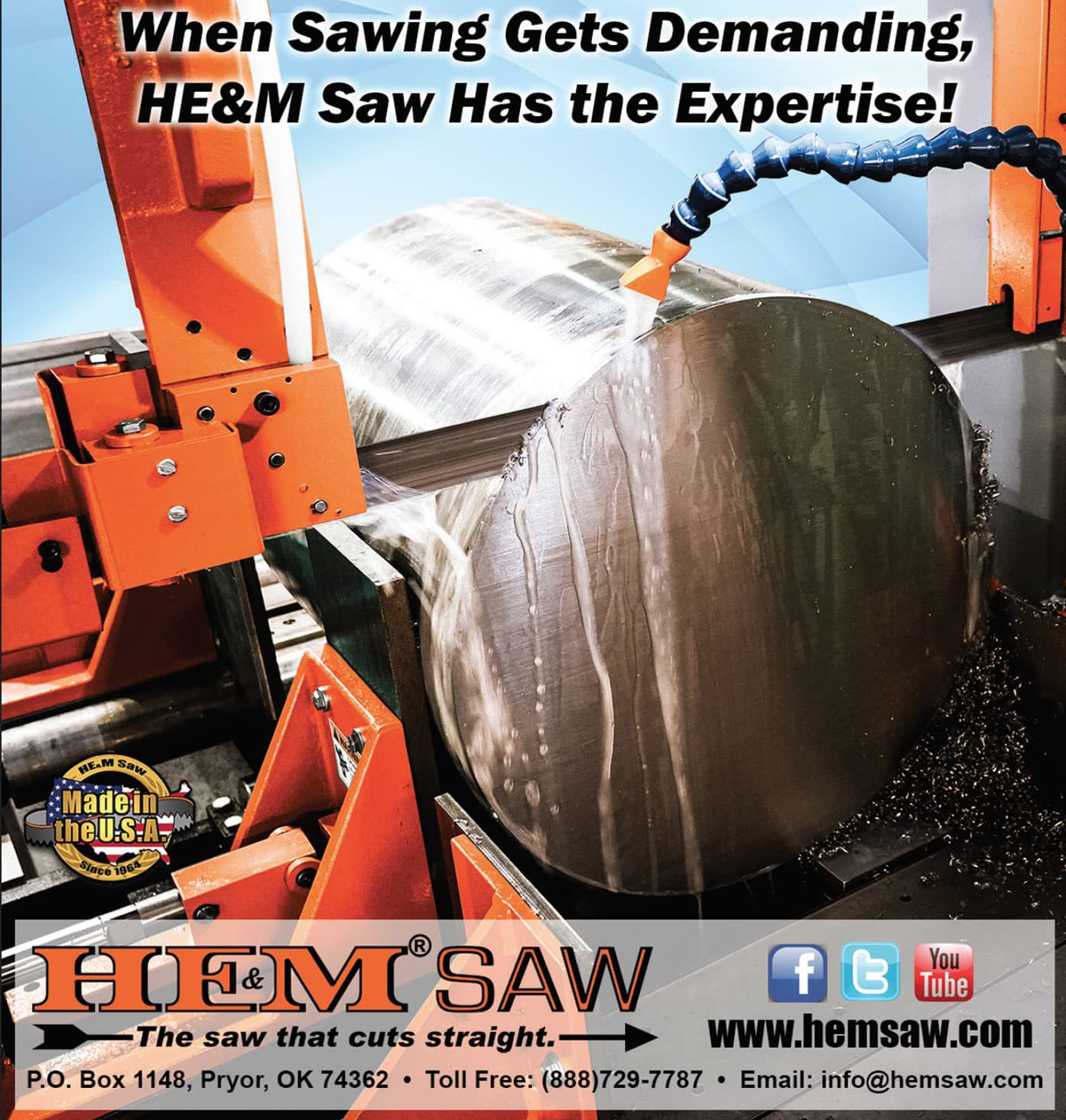

BY MICHAEL MASTERS, WIKUS SAW TECHNOLOGY

veryone’s cutting challenges differ, so understanding available blade options is important when selecting the blade best suited for an individual application. Most saws are tasked with cutting more than one type of material in a variety of sizes and shapes, so Wikus technicians typically use the 80/20 rule when recommending blades. Analyze what you’re cutting, and choose the blade that will cover 80 percent of your applications. Although the choice may not be the perfect one for your remaining 20 percent, with proper feed and speed adjustments, the blade usually will perform sufficiently in those applications, too.

Bystronic Canada, Mississauga, Ontario, appointed Leanna Chapman as customer service representative. She will be the liaison between Bystronic Canada customers and the Bystronic Canada Service department.

TCI Precision Metals, Gardena, California, appointed Matt Erickson as director of sales. He has experience in industrial operations, sales and program management.

MC Machinery, Elk Grove, Illinois, adds Craig Barbeck to its team as a regional sales representative for Northern Ohio. Barbeck will focus on laser and press brake products.

Thomas J. Gibson, president and CEO of the American Iron and Steel Institute, Washington, D.C., will retire this autumn. Gibson has led AISI since September 2008. A search for his successor has begun.

Roxana Molina was named senior vice president and chief procurement officer at Novelis Inc. Molina will lead the aluminum producer’s global metal and non-metal procurement programs.

AccuLock S series consumables include additional diffuser and nozzle types and sizes, as well as new contact tip options. The offerings now feature a new slip-on diffuser, along with a copper 3/8-inch bore tapered nozzle. Two new diffusers allow small AccuLock S consumables to be installed easily, including thread-on and slip-on versions. There are compatible brass and copper nozzles with 5/8- and 1/2-inch bores and brass nozzles with 3/8-inch bores.

Bernard, Beecher, Illinois, 855/644-9353, bernardwelds.com.

Prevention

ome survivors of conflicts from Korea and Vietnam to Iraq and Afghanistan might have difficulties adjusting to normalcy upon returning home. Those who were injured and experienced trauma are at even greater risk.

Among veterans who served during Gulf War era II (September 2001 forward), 41 percent (1.7 million) reported a service-connected disability in August 2018, according to a special report from the Census Bureau, published in March 2019. Nearly half of these veterans had a service-connected disability of 60 percent or higher. Twenty seven percent (843,000) of veterans who served during Gulf War era I (1990 to 2001) reported a service-connected disability.

According to the Department of Veterans Affairs, 11 to 20 out of every 100 veterans who served in Operations Iraqi Freedom or Operation Enduring Freedom have PTSD in a given year. Twelve percent of Desert Storm veterans and 15 percent of Vietnam War veterans have PTSD in a given year, according to an earlier study.

when [participants] get with other veterans, they realize they are not alone.

when [participants] get with other veterans, they realize they are not alone.

Prevention

ome survivors of conflicts from Korea and Vietnam to Iraq and Afghanistan might have difficulties adjusting to normalcy upon returning home. Those who were injured and experienced trauma are at even greater risk.

Among veterans who served during Gulf War era II (September 2001 forward), 41 percent (1.7 million) reported a service-connected disability in August 2018, according to a special report from the Census Bureau, published in March 2019. Nearly half of these veterans had a service-connected disability of 60 percent or higher. Twenty seven percent (843,000) of veterans who served during Gulf War era I (1990 to 2001) reported a service-connected disability.

According to the Department of Veterans Affairs, 11 to 20 out of every 100 veterans who served in Operations Iraqi Freedom or Operation Enduring Freedom have PTSD in a given year. Twelve percent of Desert Storm veterans and 15 percent of Vietnam War veterans have PTSD in a given year, according to an earlier study.

Traumatic brain injury (TBI) has been called a “signature injury” of the Iraq and Afghanistan conflicts. The Defense and Veterans Brain Injury Center reported more than 408,000 TBIs among U.S. service members worldwide between 2000 and early 2019. The majority of those TBIs were classified as mild (such as concussions).

From 2005 to 2017, there was a 43.6 percent increase in the number of suicide deaths in the general population and a 6.1 percent increase in the number of suicide deaths among veterans, according to the 2019 National Veteran Suicide Prevention Annual Report. Veterans ages 18 through 34 had the highest suicide rate in 2017 (44.5 per 100,000). The rate among this age group rose by 76 percent from 2005 to 2017.

when [participants] get with other veterans, they realize they are not alone.

when [participants] get with other veterans, they realize they are not alone.

potential

here is a scene in 2002’s Spiderman where young Peter Parker discovers his powers: Barbed cilia emerge from his fingertips so he can climb walls, he can leap from rooftop to rooftop and, finally, he’s able to throw web silk into the air.

Similarly, Bergsen Inc. wanted new tools to empower its data collection, analysis and actions and to empower its customers to use information wisely and efficiently, as well.

Bergsen distributes carbon and stainless steel and alloy long products to the machining, aerospace and automotive industries. Founded in 1974, the Santa Fe Springs, California-based service center performs heat treating, sawing, turning, centerless grinding, planing and trepanning.

Photos: alanblakely.com

pened in August 2018, the Del Valle High School Career and Technical Education (CTE) innovation space offers students 23 industry-recognized certifications in health science, graphic design, visual communications, automotive services, information technology and more. The mission of the CTE program is to provide students with relevant industry credentials while also providing college credit and experiences.

The 64,000-square-foot, two-story CTE facility, in Del Valle, Texas, contains a health-science simulation lab and mock courtroom, along with automotive repair and welding class space.

According to the school, students were awarded 493 certifications and earned 751 college credit hours during the 2017-2018 school year, the year before CTE opened. About 2,000 of the school’s 3,330 students take some classes in the center. The graduation rate for students participating in CTE programs was 95 percent in 2019, compared with 92.6 percent in 2018 and 90.7 percent in 2017, according to the Texas Education Agency.

t’s not just the cutting or the processing of a particular part. It’s how fast you can get to the next part,” says Steve West, vice president of engineered products at Chicago Tube and Iron.

The Romeoville, Illinois-based specialty steel service center stocks over 30,000 line items and has 10 branches throughout the Midwest and in Monterrey, Mexico.

“To some extent, CTI is a giant job shop,” West says. “We buy steel, we cut steel and we ship parts. Our product mix goes to every major type of OEM: military, automotive, truck and trailer, food processing, farm equipment.”

450/975-8823, fax: 450/975-7125

altitube.com

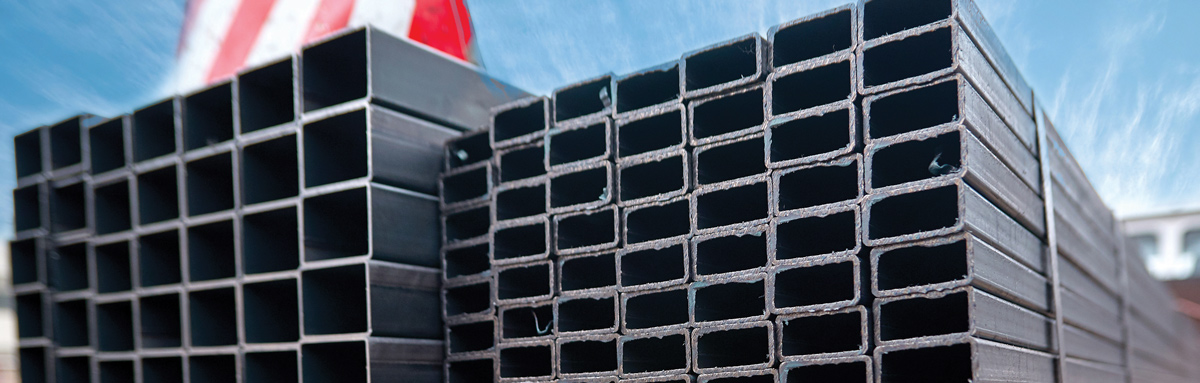

MATERIALS: Tubing, Specialty Tubular Products

SERVICES: Band Sawing, JIT Warehousing

450/653-1118, fax: 450/461-1691

acier-bouchard.qc.ca

MATERIALS: Beams, Rebar, Merchant Bar, Bar & Structural Sections, Carbon Plate, Cold Finished Bar, Expanded Metal & Grating, Tubing

SERVICES: Coil Cut to Length, JIT Warehousing

586/774-1090

alkarsteel.com

MATERIALS: Carbon Flatroll – Coil, Carbon Flatroll – Cold Roll, Carbon Flatroll – Galvanized

SERVICES: Slitting

773/522-3100

chartersteeltrading.com

MATERIALS: Carbon Flat Roll – Coil, Carbon Flat Roll – Cold Roll, Carbon Flat Roll – Coated, Carbon Flat Roll – Ctl Sheet (Including Ctl Floor Plate)

SERVICES: Coil Blanking, Coil Cut to Length, Online Order Tracking, ISO Certified, Just In Time Warehousing, Slitting

216-481-6600, fax: 216-481-8473

chesterfieldsteel.com

MATERIALS: Carbon Flat Roll, Hot-Rolled, Hot Rolled Pickled and Oiled, Cold Rolled, Enameling Iron, Galvanized, Galvanneal, Zinc Magnesium Coated, Prepaint, CTL Sheet, Slit Coil, HSLA, AHSS, DP, CP and XPF Grades

SERVICES: Slitting, Coil Blanking, Coil Cut to Length, ISO Certified, JIT Warehousing

323/726-3503

jtcsteel.com

MATERIALS: Beams, Carbon Flat Roll—Hot Rolled Coil, CTL Sheet & Floor Plate, Carbon Plate, Cold Finished Bar, Merchant Bar, Bar & Structural Sections, Tubing

SERVICES: Band Sawing

&logistics

f you make listening and observation your occupation, you will gain much more than you can by talk,” said British Army Lt. Gen. Robert Baden-Powell, who was also a writer and launched the Boy Scout Movement in 1910.

After selling a successful publishing business, Matthew Kane was at a crossroads at age 40, and he was not ready to retire. He met a group of truck drivers at a veterans’ fundraiser in Washington, D.C., who told him about the difficulties they faced in the industry, from being at the mercy of freight brokers to insurance costs.

“I wanted to know more, so I packed an overnight bag and drove 44 states for eight and a half months, purchased thousands of buffet dinners and coffees at truck stops.”

hoosing the correct tools can be the defining factor in a true representation for testing. In an ideal scenario, testing preparation shouldn’t impart any additional changes to the original material but many traditional cutting machines leave residue or distort the material.

As stated in ASTM E8/E8M–13A under Subsection 6.1.3, “Improperly prepared test specimens often are the reason for unsatisfactory and incorrect test results. It is important, therefore, that care be exercised in the preparation of specimens, particularly in the machining, to maximize precision and minimize bias in test results.”

However, there is an option for test prep that is fast, clean and versatile yet might be overlooked. Abrasive waterjets can work as a valued solution for all types of metallurgy testing. By cutting testing coupons on a waterjet, some manufactures are seeing up to nine times faster preparation speed.

utomation is efficient, but it isn’t a silver bullet. It has to be applied with thought and purpose. Microsoft co-founder Bill Gates has suggested that automation applied to an efficient process will “magnify the efficiency,” while “automation applied to an inefficient process will magnify the inefficiency.”

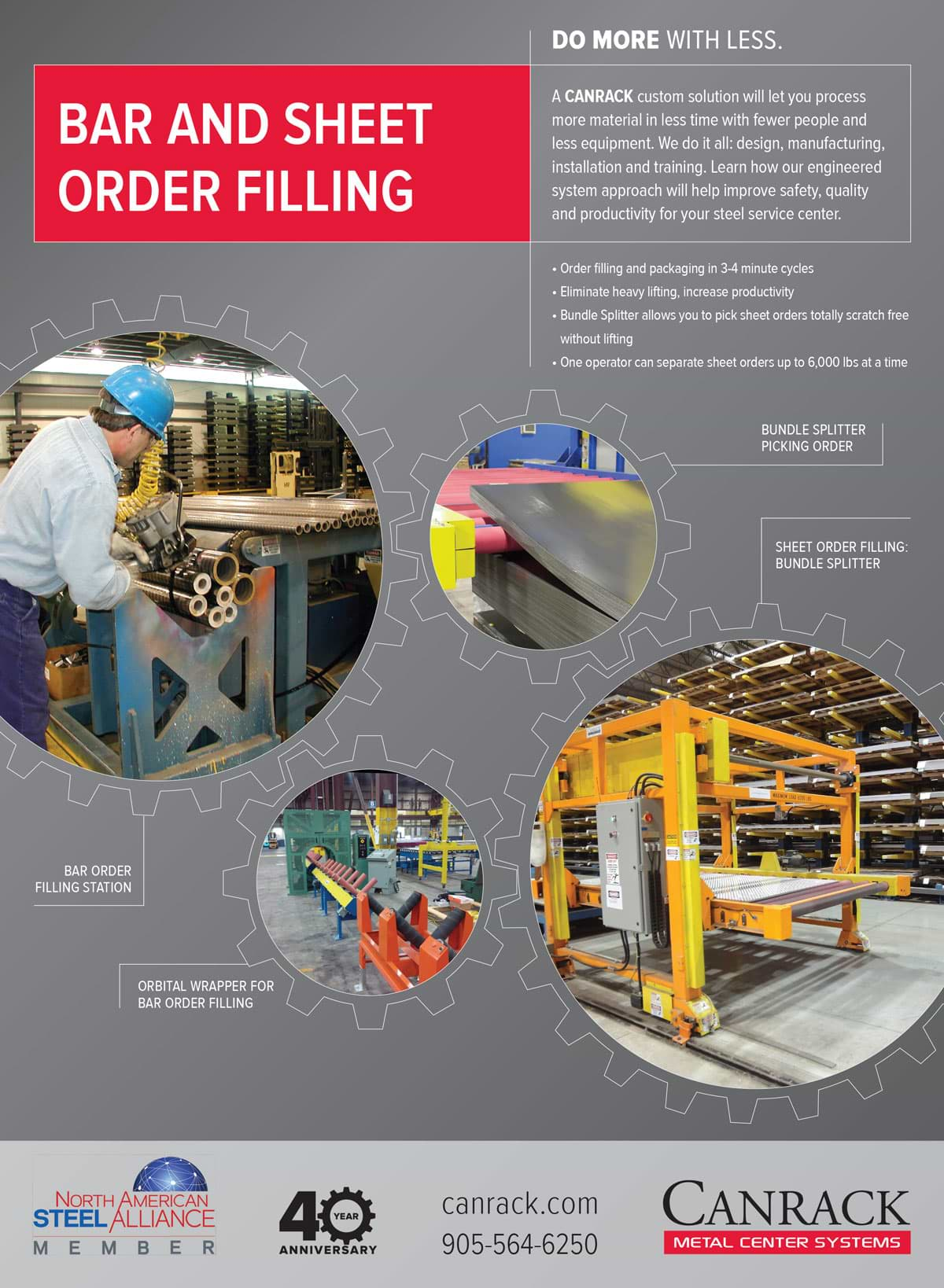

As companies strive to move material through operations quickly and efficiently, conveyors and packaging systems can help eliminate bottlenecks and manual labor when properly implemented. According to Commerce City, Colorado-based Steel Storage Systems, a designer and manufacturer of custom storage and handling equipment, a good conveyor system will increase productivity and improve safety.

“A properly devised system will not only increase output but also can have downstream benefits such as better personnel and crane utilization. We often arrange a system to serve multiple machines or where one operator can effectively run two machines simultaneously,” a company spokesperson says.

o not let resonance destroy your sawing machine and ruin efficiency within your shop. Learn how to test resonance and prevent a catastrophic outcome.

What is resonance? How do I prevent resonance from ruining my machine?

Resonance occurs when a vibratory system is subject to an external pulsing force and the excitation frequency is the same as the natural frequency of the system. When this happens, and there is no damping in the system, amplitude continues to grow infinitely. Typically, machines are designed with some damping in the system so that the amplitude reaches a finite peak value. Without proper damping, the displacements can escalate to a point where the system can no longer support its function, and this can lead to complete destruction of the system.

partingshot

Advertiser Index

View Index

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.modernmetals.com

312/654-2309, Fax: 312/654-2323

mdalexander@modernmetals.com

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@modernmetals.com

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Oklahoma, Pennsylvania, South Carolina, South Dakota, Tennessee, Texas

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@modernmetals.com

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@modernmetals.com

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@modernmetals.com

Modern Metals® (ISSN 0026-8127, USPS 357-640) April 2020, Vol. 76, No. 4 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.