hoosing the correct tools can be the defining factor in a true representation for testing. In an ideal scenario, testing preparation shouldn’t impart any additional changes to the original material but many traditional cutting machines leave residue or distort the material.

As stated in ASTM E8/E8M–13A under Subsection 6.1.3, “Improperly prepared test specimens often are the reason for unsatisfactory and incorrect test results. It is important, therefore, that care be exercised in the preparation of specimens, particularly in the machining, to maximize precision and minimize bias in test results.”

However, there is an option for test prep that is fast, clean and versatile yet might be overlooked. Abrasive waterjets can work as a valued solution for all types of metallurgy testing. By cutting testing coupons on a waterjet, some manufactures are seeing up to nine times faster preparation speed.

When cutting any type of metal coupon, traditional CNC machines impart heat, add oil or coolant, and leave burrs. Cutting with laser, plasma, EDM or traditional saws each transfer some level of heat that will need to be dealt with in a secondary process, in addition to leaving slag or chatter marks.

ASTM standards require specimens for testing should be “free of cold work, notches, chatter marks, grooves, gouges, burrs, rough surfaces or edges, overheating or any other condition which can deleteriously affect the properties to be measured.”

Waterjets impart no heat, meaning additional processes can be eliminated. Cutting material on a waterjet with a slow speed can ensure a smooth finish for testing specimens. Ultimately, this means that the test sample will be truthful to the original material, leaving no doubt about the results.

With finished product destructive testing, there may be several different materials in a dense part. This can be an issue for CNC machines where different materials are cut with different bits at different speeds. Waterjets will cut cleanly through several layers of different materials without changes to machine setup.

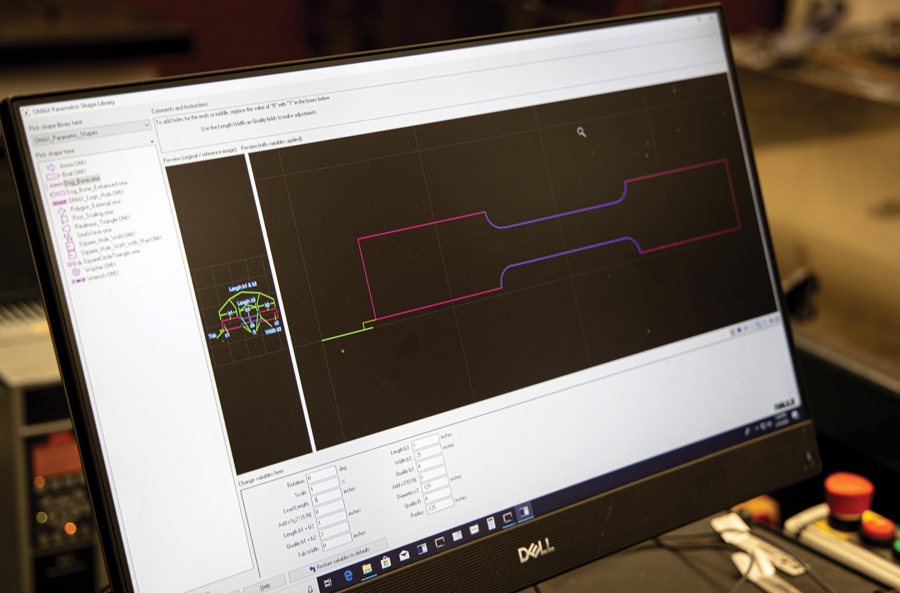

Because waterjet is not a hard tool but rather a flexible cutting medium, there is a tendency for the jet to leave taper. However, with taper compensation, the software controlling the jet understands the way the head behaves and places the taper on the remaining stock rather than on the cut sample.

the ability to cut and mark your test samples with a single machine saves time and money.

the ability to cut and mark your test samples with a single machine saves time and money.

Etching lot numbers on a sample is typically done in a costly laser etching machine, creating yet another step in the testing process. A few waterjet brands already have the capability to etch built into their software package. OMAX’s IntelliETCH can engrave patterns, logos or lot numbers on surfaces. The OMAX Controller varies speeds to etch the desired pattern. This is in addition to other standard etching and scribing tools. The ability to cut and mark your test samples with a single machine saves time and money.

With a cutting envelope of 12 inches by 12 inches, the ProtoMAX is powerful but compact. The pump and cutting table are on casters for easy relocation. Work material is submerged under water for quiet cutting that won’t disrupt work spaces. With a clamshell cover, the ProtoMAX also provides a safer environment.