Chairman of the Executive Board of the Materials Services division

President and CEO Ken Mac Metals and thyssenkrupp Steel Services

Chief Financial Officer, thyssenkrupp Materials NA Inc.

We’re relentlessly committed to passionate customer service, offering versatile operations and the industries’ most expansive national footprint.

Come ride the VORTEQ wave of momentum for your coil coating needs! Let’s get started at vorteqcoil.com

Features

etals supply continued to be at a choke point during February, according to the latest U.S. Census report on durable goods manufacturers’ shipments, inventories and orders. Unfilled orders for primary metal producers totaled $35.9 billion in February (not seasonally adjusted), up 4 percent from January and rising 11.1 percent from $32.3 billion in February 2020.

Unfilled orders at metal fabricators neared $80.2 billion (not seasonally adjusted), increasing 2.6 percent from January and jumping 8.7 percent from almost $73.8 billion in February 2020.

A March 24 Morgan Stanley Research report stated that commodity prices were at a sweet spot. “In our commodities team’s view, market drivers have been almost universally positive through first quarter 2021, supported primarily by a consumer and manufacturing-led global recovery, speculative inflows, limited supply growth and disrupted shipping.” It doesn’t help when a giant container ship runs aground in the Suez Canal, blocking all waterborne traffic.

UACJ Automotive Whitehall Industries, which extrudes aluminum automotive components and assemblies, will take over an existing distribution center in Flagstaff, Arizona, to create a new facility making parts for electric vehicles. Local economic development officials estimate that the company will invest up to $60 million on the expansion. UACJ Whitehall expects to launch production in April.

Lion Electric, which builds all-electric trucks and buses, will build a battery manufacturing plant in Quebec. Slated for an early 2023 startup, the Cdn. $285 million factory will produce battery packs and modules made from lithium-ion cells. With a planned annual production capacity of 5 gigawatt-hours in battery storage, Lion will be able to electrify about 14,000 medium and heavy-duty vehicles per year.

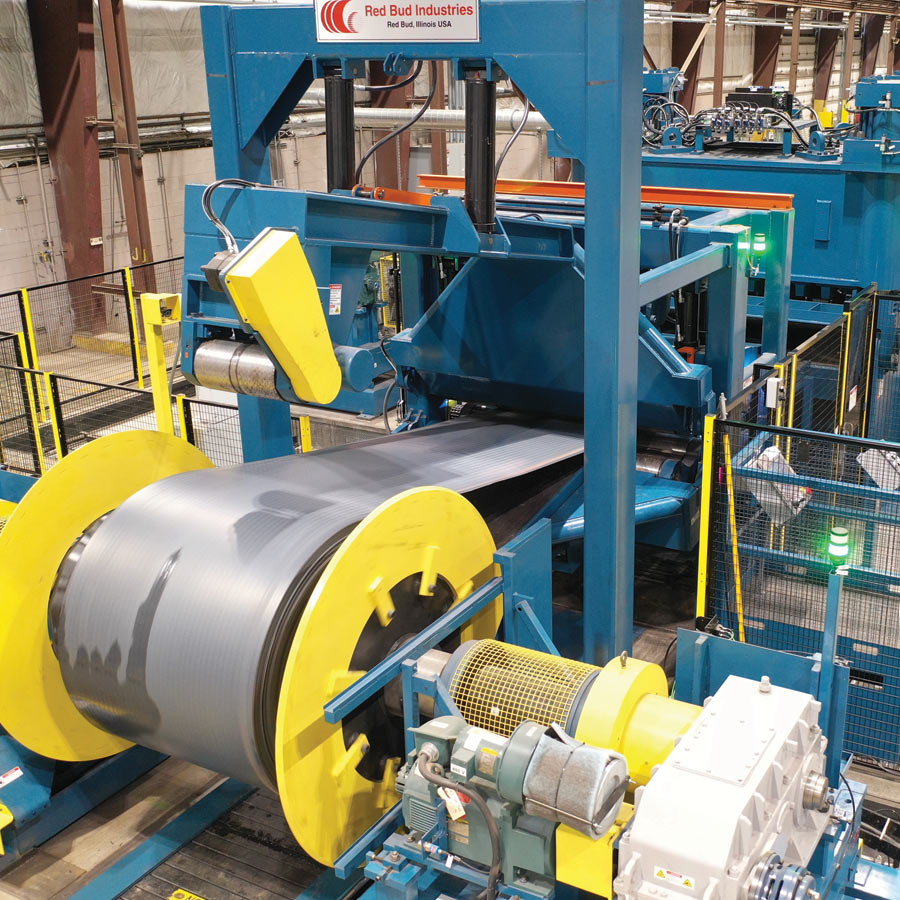

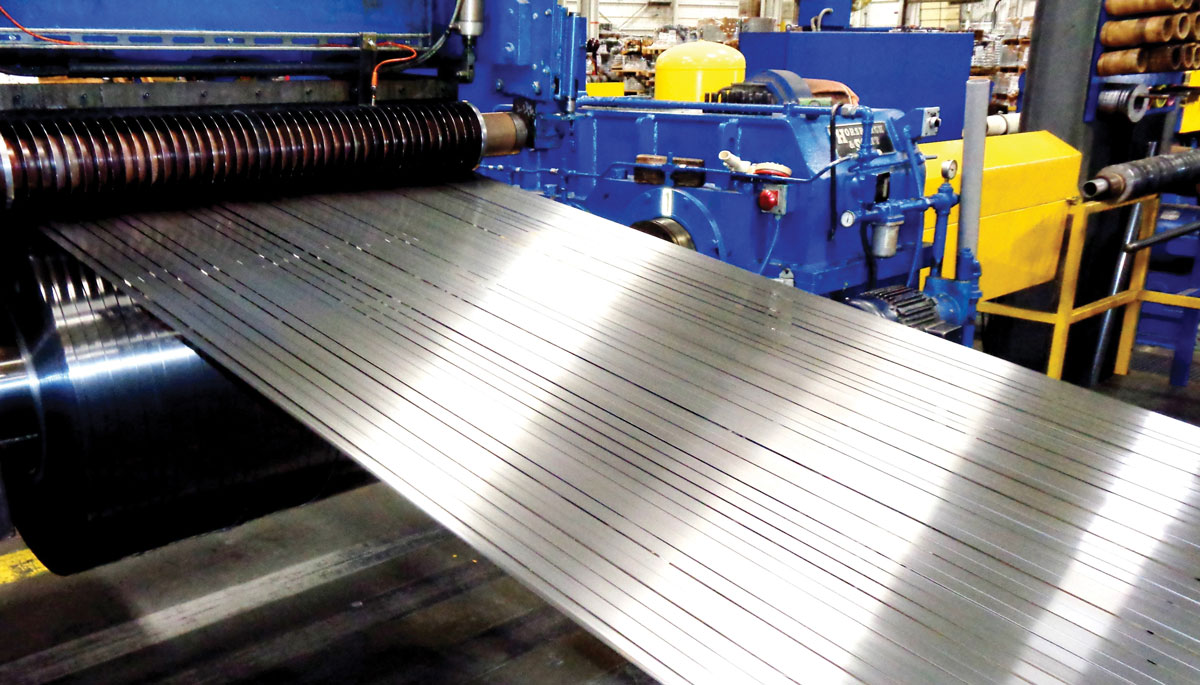

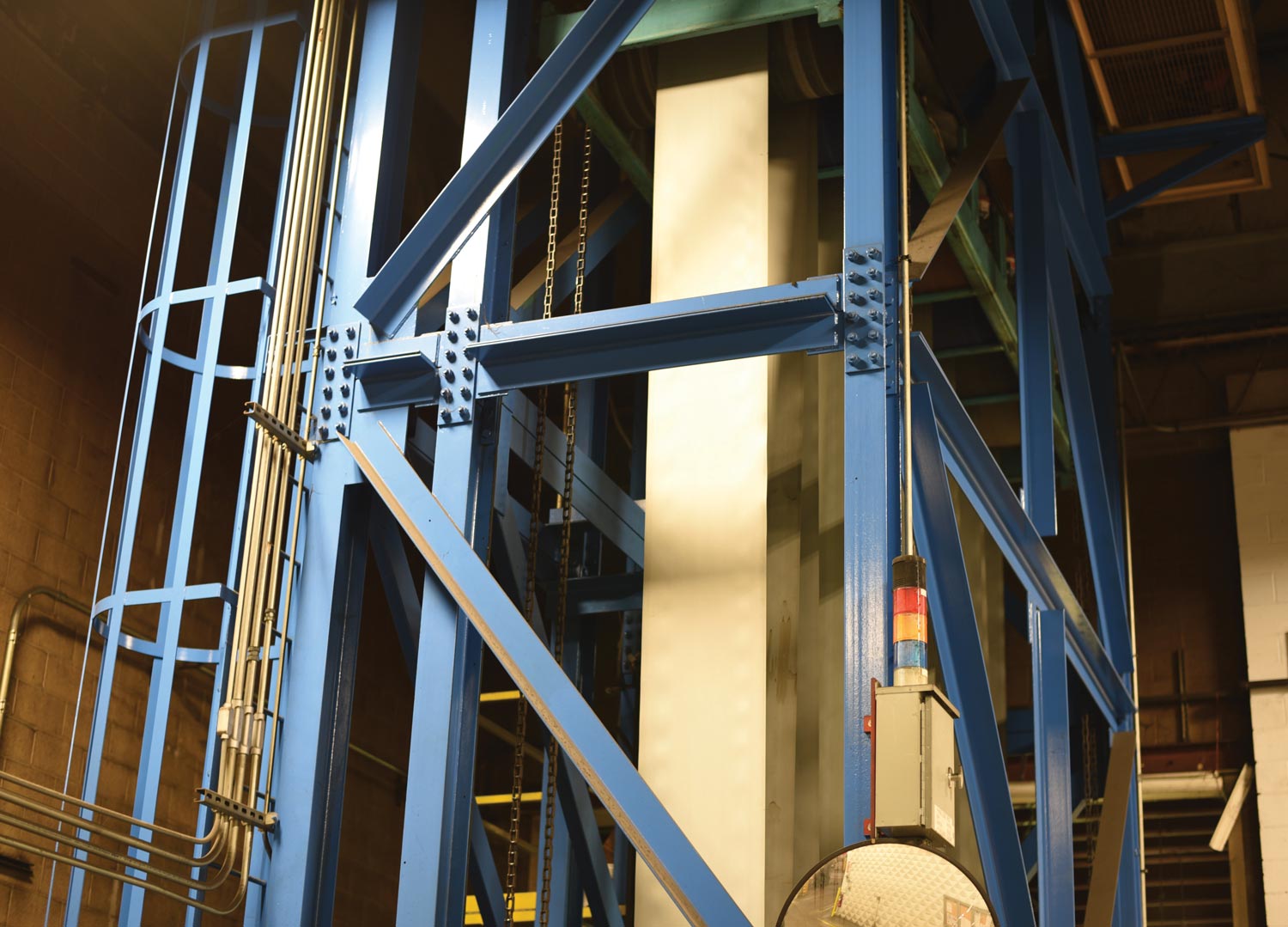

emory-free steel has become a standard requirement for metal processors that burn or laser cut material into perfectly flat parts, which has caused service centers and toll processors alike to reevaluate the capabilities of their existing equipment. Coil Steel Processing (CSP) is one example. Founded in 2014, CSP processes up to 100,000 tons of steel a year at its Toledo facility. President Kevin Friedman, who had previous service center experience, started CSP by purchasing two older Herr-Voss cut-to-length lines that relied on roller leveling technology. Both CTL lines could process material up to 72 inches wide; one was for material up to 1/4 inch thick, the other for material up to 1/2 inch thick.

To give customers what they wanted, Friedman understood that a stretcher leveling upgrade was necessary. Developed over the past 25 years, the technology “delivers sheets that are completely memory free, so they remain perfectly flat as parts are cut out on burning tables,” Friedman says. “Memory-free sheet has become the standard requirement for certain premium product applications and end markets, and stretcher-leveling technology is becoming the standard in our industry. Many fabrication facilities are now specifying stretcher-leveled sheets.”

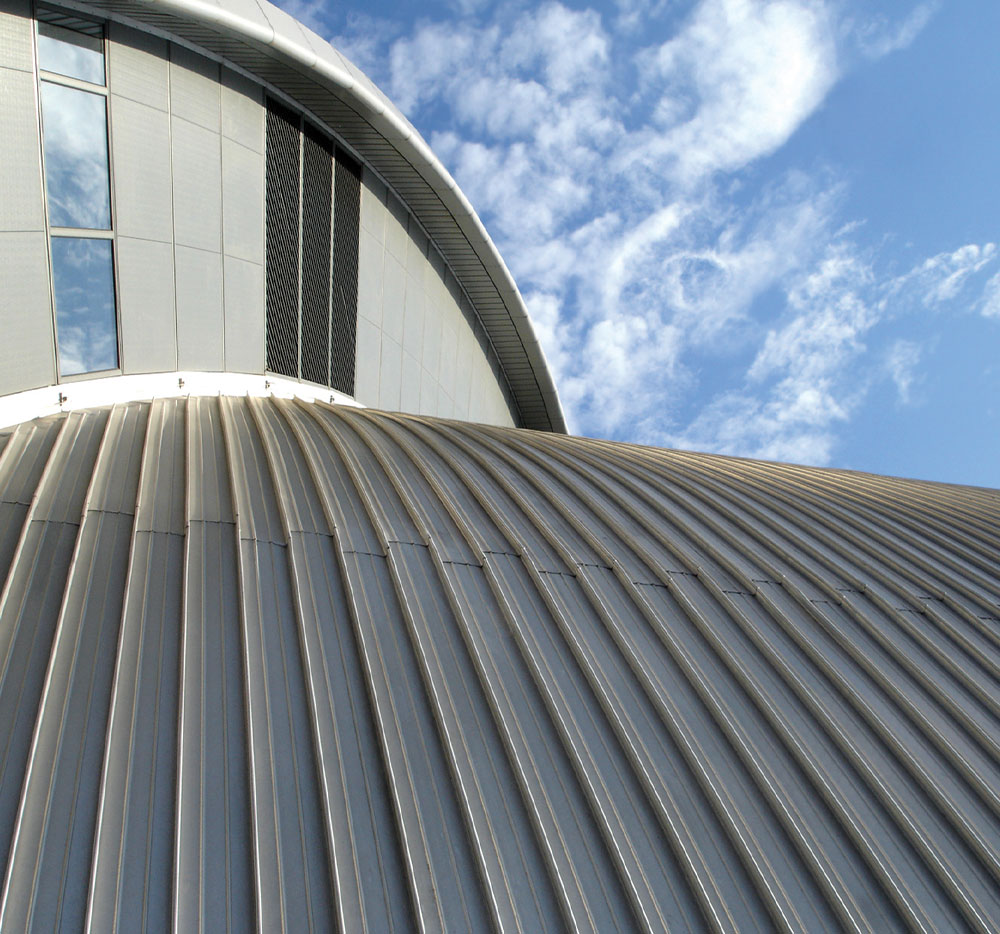

After seeing stretch cycle times improve and machine designs evolve, Friedman determined “it was time to make a move.” CSP processes coils into sheets, focusing on a range between 16 gauge and 5/8 inch thick. The material includes hot-rolled, hot-rolled pickled and oiled, cold-rolled, coated and floor plate. End customers include industrial manufacturing, such as fabrication, metal building products, racking and conveyor systems; construction, such as tanks and trench boxes, shielding equipment, observatories and greenhouses; and transportation, including truck, trailer and recreational vehicle parts, among others.

450/975-8823, fax: 450/975-7125

altitube.com

SERVICES: Band Sawing, JIT Warehousing

450/653-1118, fax: 450/461-1691

acier-bouchard.qc.ca

SERVICES: Coil Cut to Length, JIT Warehousing

314/382-6500, 314/382-4035

cardinalsteel.com

SERVICES: Band Sawing, Beam Splitting, Plate Cutting: Plasma, Shearing, Structural Fabrication, JIT Warehousing

509/924-6363, fax: 509/924-6924

cdametals.com

814/467-5578, fax: 814/467-9825

glossersteel.com

SERVICES: Band Sawing, Plate Cutting: Oxyfuel and Plasma, Shearing

ome time ago, the American Institute of Steel Construction (AISC), Chicago, surveyed its members about the technologies they deployed in their companies.

The survey “revealed our industry was still largely using fax and email attachments,” says Luke Faulkner, AISC’s director of technology integration. “Beyond that, we found that the existing electronic data interchange (EDI) systems were all proprietary, which meant that an interested buyer would potentially have to produce a separate inquiry for each seller.

“AISC identified a rather large potential upside in offering a standard platform for EDI, namely that it could potentially cut hours of manual entry, scrubbing and refining out of the procurement process,” says Faulkner. “We further recognized that the majority of the industry would be better served and more likely to take advantage of automated information transfer if there was a single standard for it versus a different EDI portal for every vendor.”

hrough acquisitions in key geographies, upgrades of its processing lines, and the creation of an interactive platform for rapidly communicating with customers, leadership at Vorteq Coil Finishers LLC believes the company is reaching its potential as a national presence.

“We closed an acquisition at the end of 2019,” says CEO Jim Dockey, in reference to Western Metal Decorating, since rebranded as Vorteq Pacific. “It was a well-run family business that performed coil and sheet coating.” The company’s owners, a brother and sister team, wanted to retire.

Within Vorteq’s long-term strategic plan, “we wanted to add capabilities or geography or both, and this one gave us a footprint on the West Coast,” Dockey says. Western Metal Decorating was the third acquisition completed over a four-year period. “Now we have nine coating lines dotting the landscape from California to Pennsylvania. This puts us in a position to service a wider range of customers, including national accounts like those that manufacture building products. And we are able to roll out to national businesses.”

any businesses are becoming more mobile as a result of the COVID-19 pandemic, and this is fueling a rise in demand for specialty vehicles—everything from on-the-go healthcare services, such as blood donation vans and mobile clinics, to food trucks. According to the marketing intelligence and advisory firm Mordor Intelligence, the specialty vehicle market was valued at $92.28 billion in 2020 and is expected to grow to $113.2 billion by 2026.

Fort Lupton, Colorado-based Summit Bodyworks has 30 years of experience creating innovative designs to fulfill this market need. The company recently delivered the first vehicle in its Peak body series, a 26-foot-long fiberglass mobile medical unit, to the Denver Health Department. It’s equipped with three separated rooms, including two examination beds, a blood draw chair and refrigeration units.

Some other Summit projects include a mobile chemotherapy compounding laboratory for Cancer Care Specialists of Illinois, which sits on a Freightliner M2 chassis, and a Multi-Purpose Command and Transport unit for the Meeker County, Minnesota, sheriff’s department.

abricators have always worked to become faster and more flexible, but advances in equipment technology make that goal easier to attain. Riker Products has been bending and processing tube since Walter Riker founded the Toledo, Ohio, company in 1932. It has streamlined its operations over the last several years by installing lasers and electric benders from BLM Group, Novi, Michigan.

Riker and BLM Group began working together after meeting at a Fabtech show, says Shelly Vargo, Riker’s executive vice president. “We needed to do some upgrading on our shop floor, so we took a team of employees to the show.” After reviewing quotes and visiting BLM Group’s North American headquarters in Michigan, the Riker team believed the machine tool manufacturer was a good match.

Riker Products installed two Elect 150 benders in 2018—and “once we ordered those, BLM Group invited two people from Riker to join them in Italy, where they have their main headquarters,” Vargo notes. There, they saw other products in the BLM Group line, watched parts run and “asked all the questions we wanted to ask. While we were there, we came to the decision to not only upgrade the benders but also add lasers, which would help us automate and diversify,” says Vargo.

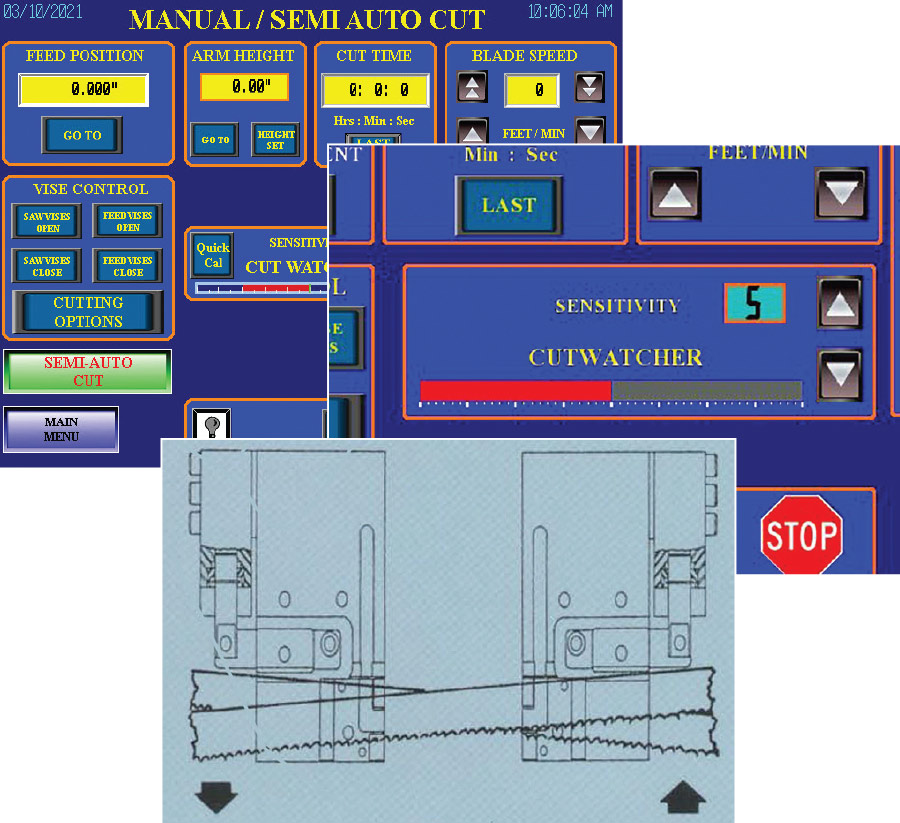

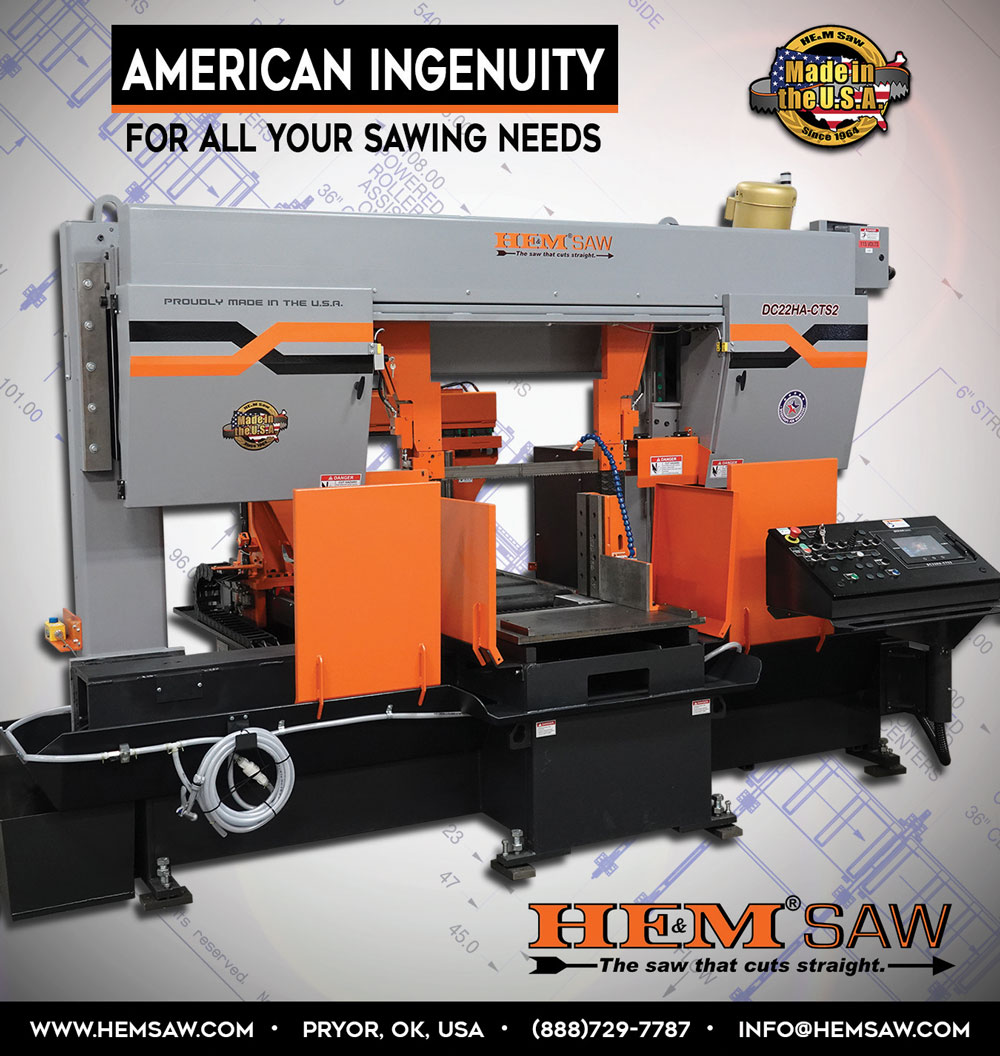

and saws, band saw blades—and band saw features in general—have undergone technological improvements and innovations in recent years, although sometimes it has seemed like these innovations don’t happen as quickly as they do with other CNC machines. New developments are changing that, however. Many new and revitalized features are creating a “synergistic” result, where the sum of the various components working together far outweighs the benefit of the effects of the individual features.

The introduction of computer controls added opportunities for band saws to utilize new technology as well as improve the utility of pre-existing features. This, along with blade research and development, has improved sawing performance and efficiency tremendously over the years. Metal-cutting band saw blades have experienced many modifications and changes that enable improved sawing performance, particularly with metals that are difficult to cut due to various conditions, including work hardening and reducing vibration. Carbide-tipped blades have been common for years now, and they, along with bi-metal blades, have undergone increasing R&D, resulting in continued improvement and notable success in performance.

Akzo Nobel Coatings Inc., Columbus, Ohio, 614/294+3361, coilcoatings.akzonobel.com.

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.modernmetals.com

312/654-2309, Fax: 312/654-2323

mdalexander@modernmetals.com

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@modernmetals.com

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Oklahoma, Pennsylvania, South Carolina, South Dakota, Tennessee, Texas

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@modernmetals.com

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@modernmetals.com

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@modernmetals.com

Modern Metals® (ISSN 0026-8127, USPS 357-640) APRIL 2021, Vol. 77, No. 4 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Modern Metals® (ISSN 0026-8127, USPS 357-640) APRIL 2021, Vol. 77, No. 4 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.