and saws, band saw blades—and band saw features in general—have undergone technological improvements and innovations in recent years, although sometimes it has seemed like these innovations don’t happen as quickly as they do with other CNC machines. New developments are changing that, however. Many new and revitalized features are creating a “synergistic” result, where the sum of the various components working together far outweighs the benefit of the effects of the individual features.

The introduction of computer controls added opportunities for band saws to utilize new technology as well as improve the utility of pre-existing features. This, along with blade research and development, has improved sawing performance and efficiency tremendously over the years. Metal-cutting band saw blades have experienced many modifications and changes that enable improved sawing performance, particularly with metals that are difficult to cut due to various conditions, including work hardening and reducing vibration. Carbide-tipped blades have been common for years now, and they, along with bi-metal blades, have undergone increasing R&D, resulting in continued improvement and notable success in performance.

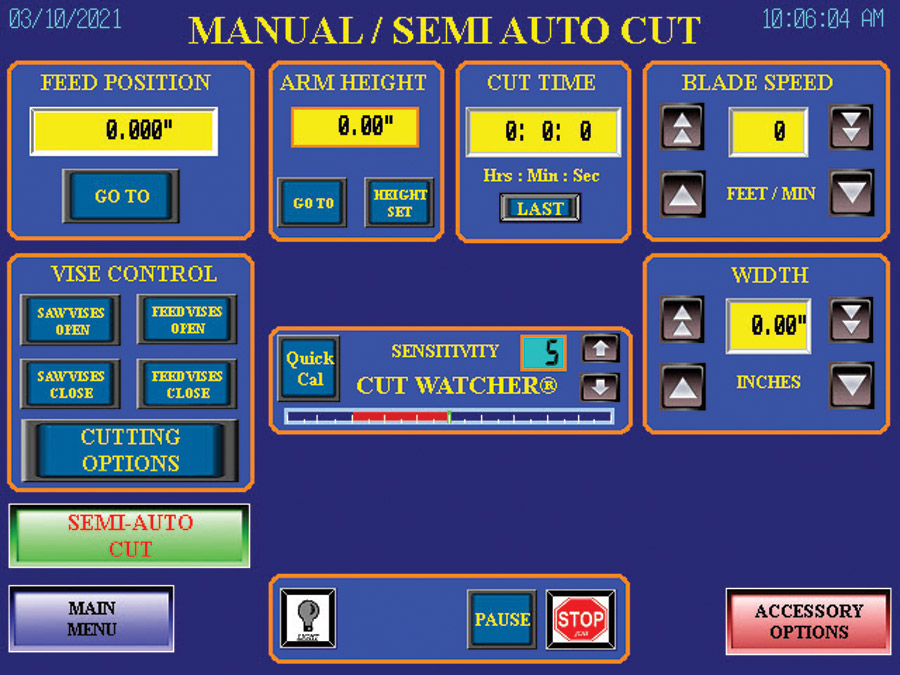

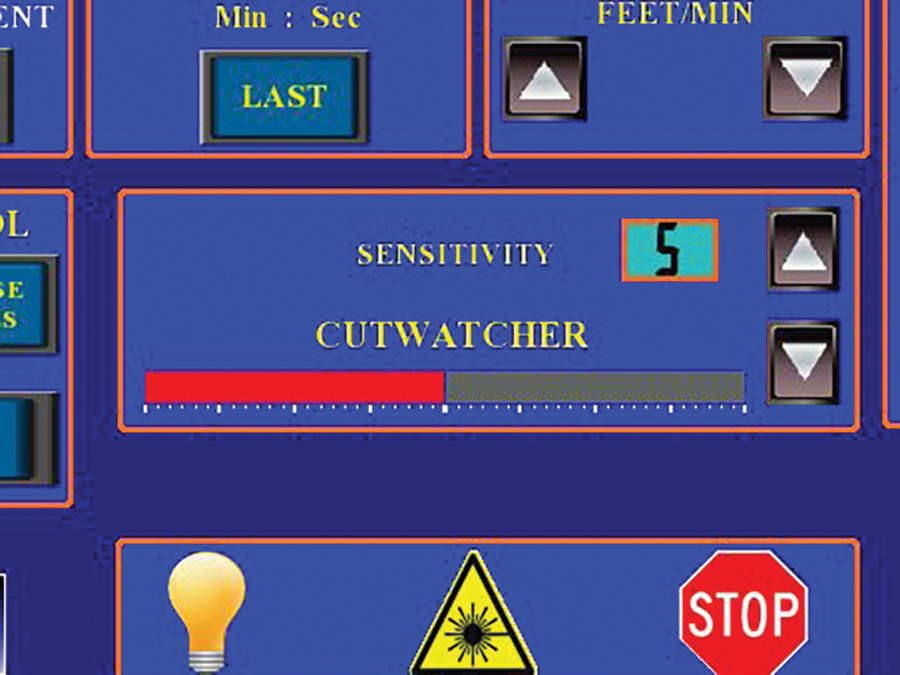

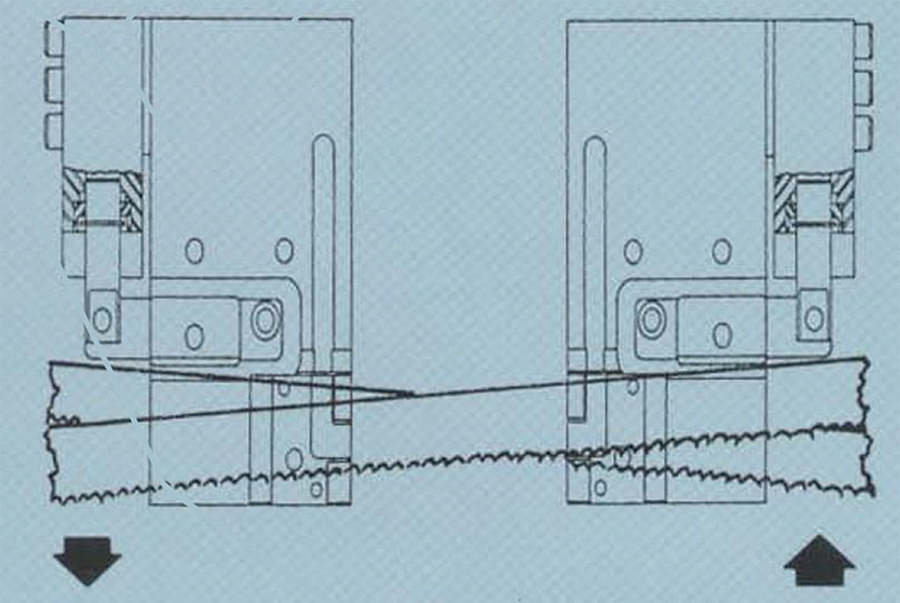

Likewise, as pressure on the blade from one enhancer is removed and pressure is exerted by the other enhancer on that side of the cutting, the chip removal is switched from one side of the cut to the other. Results include increased blade life and reduced sawing times, especially on harder-to-cut materials. Monitoring the programmable cycle time and observing the chips that result from the cutting can fine-tune the cutting process.

Saw … advancements can add to a blade’s overall performance, which includes reducing cutting times and increasing blade life.

Saw … advancements can add to a blade’s overall performance, which includes reducing cutting times and increasing blade life.

M.K. Morse has been manufacturing saw blades in Canton, Ohio, for over 50 years and has developed certain technologies for band saw blades, including Jawbreaker, which features patent-pending Plyometric cutting action and dual-patented Kerflock technology. “Plyometric cutting action keeps the tips engaged in the material while cut angles change dynamically throughout the cut,” says Sekhar Rakurty, head of research at M.K. Morse. Blades with KerfLock technology are precision ground to minimize side-to-side forces. This creates a constant kerf that extends blade life by reducing tooth wear and pinching. “Combined, these technologies allow users to cut up to 30 percent faster while extending blade life up to 100 percent when cutting superalloys and other hard-to-cut materials,” Rakurty says.

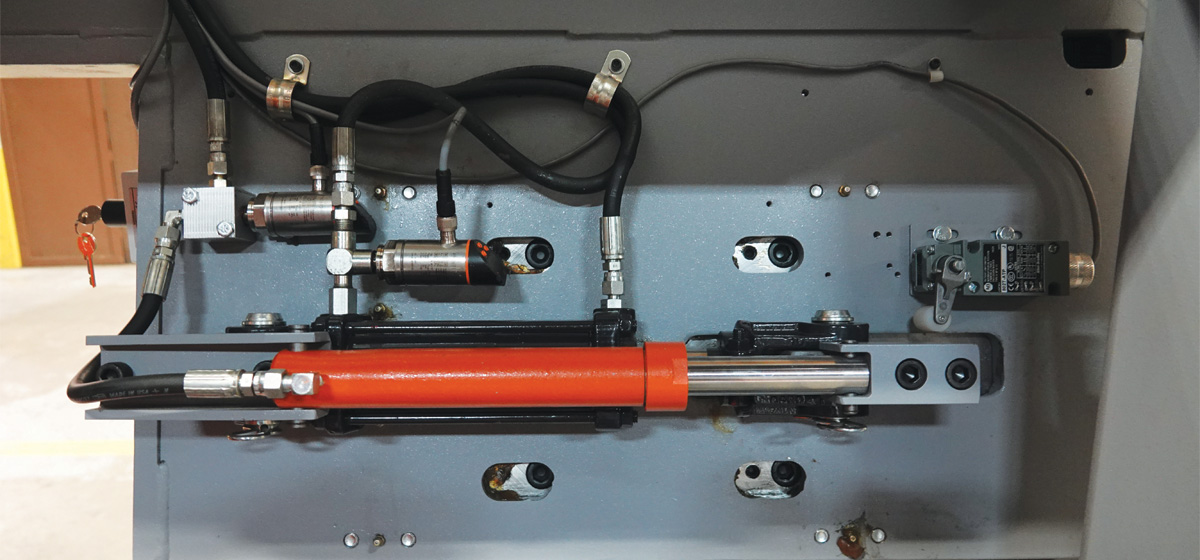

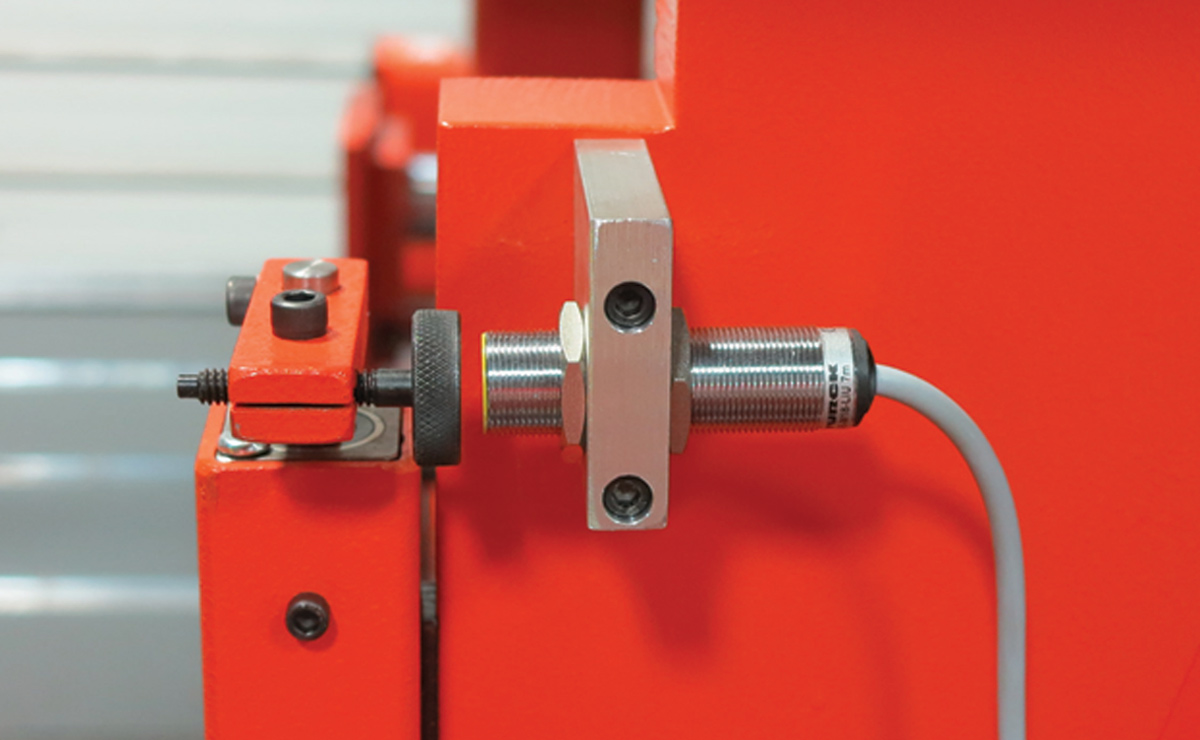

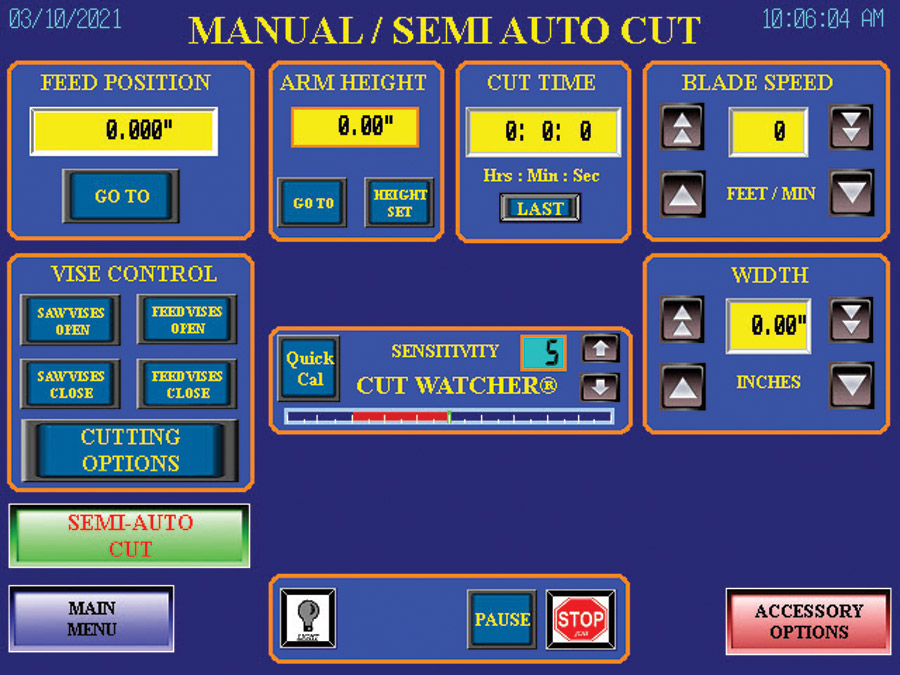

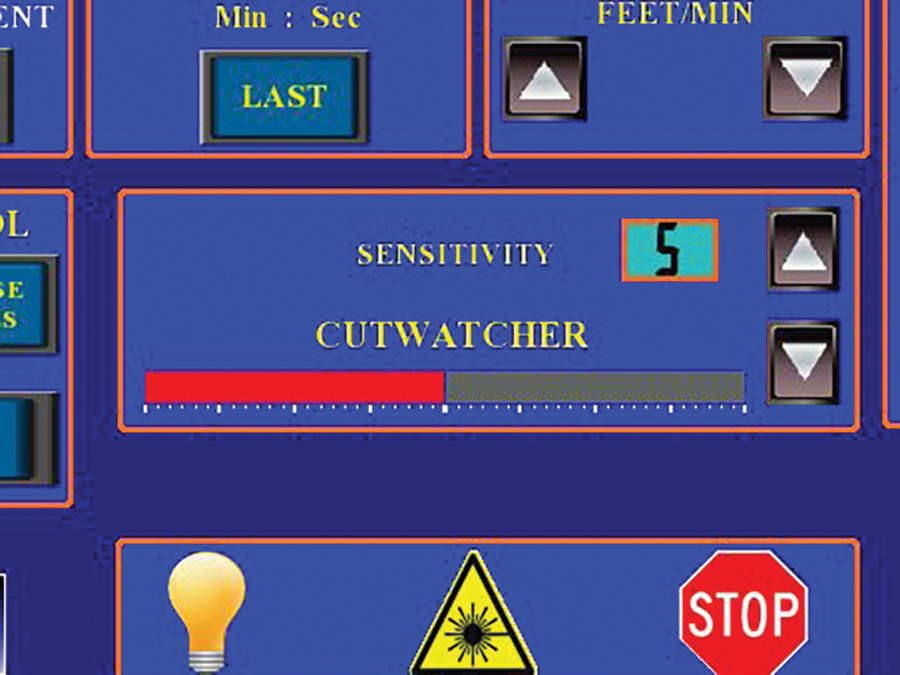

Cut Watcher automatically increases tension on the blade using a cylinder to exert additional pressure. The increased tension makes the blade more rigid, helping it to maintain a straight cut.

Developments in band saw technology occur more quickly than ever before and, along with improvements and updates to existing features, are operating more like the other CNC machines that the industry has employed for years.