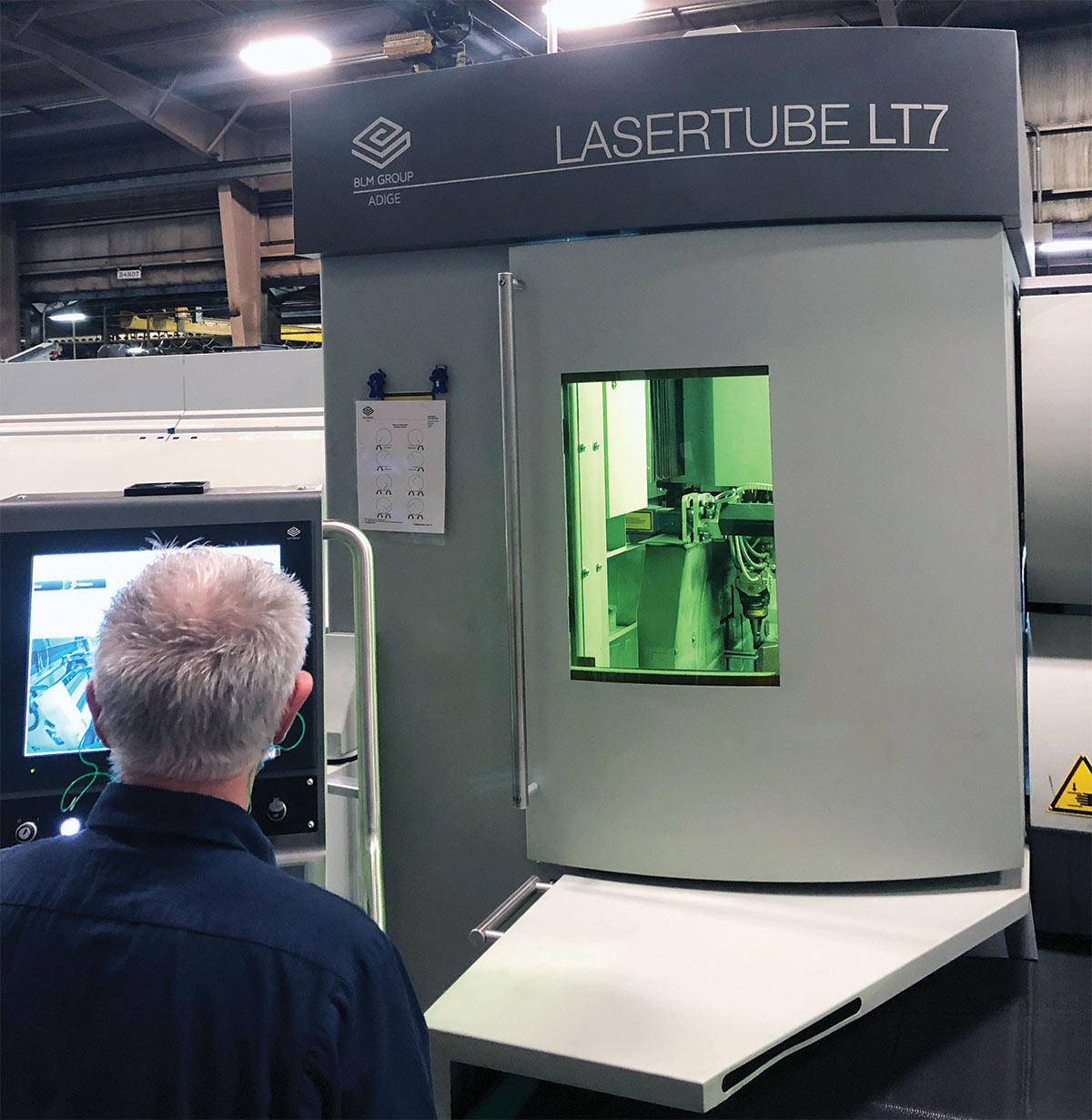

abricators have always worked to become faster and more flexible, but advances in equipment technology make that goal easier to attain. Riker Products has been bending and processing tube since Walter Riker founded the Toledo, Ohio, company in 1932. It has streamlined its operations over the last several years by installing lasers and electric benders from BLM Group, Novi, Michigan.

Riker and BLM Group began working together after meeting at a Fabtech show, says Shelly Vargo, Riker’s executive vice president. “We needed to do some upgrading on our shop floor, so we took a team of employees to the show.” After reviewing quotes and visiting BLM Group’s North American headquarters in Michigan, the Riker team believed the machine tool manufacturer was a good match.

Riker Products installed two Elect 150 benders in 2018—and “once we ordered those, BLM Group invited two people from Riker to join them in Italy, where they have their main headquarters,” Vargo notes. There, they saw other products in the BLM Group line, watched parts run and “asked all the questions we wanted to ask. While we were there, we came to the decision to not only upgrade the benders but also add lasers, which would help us automate and diversify,” says Vargo.

The benders are improving our efficiencies and operational excellence tremendously.

The benders are improving our efficiencies and operational excellence tremendously.

Having a set of machines from the same manufacturer is helpful because “they communicate with each other. The benders communicate to the laser and the laser can also communicate with the benders—both programming and scheduling aspects.”

In addition to the new business, Mark Foster, Riker’s president, says the two lasers have “helped operational efficiencies on the welding side. We’re now able to cut tubes on the tube lasers and take them directly to welding without a lot of the secondary operations that we have needed in the past. Instead of having to move a particular part throughout the shop for multiple cuts, we can do it all on the tube laser and go right into welding.”

Riker Products, Toledo, Ohio, 800/292-9744, rikerprod.com.