a nationwide network.

Our team is here, there and everywhere ready to help when you need it. Let us bring your business the ultimate flexibility and competitive edge so you can deliver the most consistent product to your customers!

serving metal service centers, fabricators and OEM/end users since 1945

serving metal service centers, fabricators and OEM/end users since 1945

Features

dvocates for metals consumption issued statements of strong support after the Senate passed a $1 trillion infrastructure bill, which was to be reviewed by the U.S. House of Representatives during the last days of August.

“We applaud the Senate for advancing this bipartisan legislation that will spur economic growth and job creation throughout the country,” says Kevin Dempsey, president and CEO of the American Iron and Steel Institute, Washington, D.C.

teel was an integral component when Henry Ford’s first Model T rolled off the assembly line in 1908. Fast forward 113 years and steel remains a key ingredient in the production of today’s “horseless carriages.”

Automotive design and manufacturing technologies have changed dramatically over that timeframe. What hasn’t changed is automakers’ reliance on steel to get the job done on highways, byways and dirt roads.

lue collar” is a term I despise. My collar was blue the day I wrote this article, and I work behind a desk. I know a welder who makes nearly double my salary. Categorizing career paths by the color of one’s collar is irrelevant and demeaning. Forget about the collars, focus on the career, and stop stigmatizing a critical function in society.

For decades, students have been steered away from industrial work. Manufacturing was painted as dangerous, dark, dirty, or only for those that couldn’t make it through a four-year college. If this misinformation campaign wasn’t so rampant, the $1.7 trillion in U.S. student debt might be a bit lower.

“Price increases on carbon products continue to climb as lead times remain extended. LME aluminum [prices] continued to rise into the third quarter on strong global demand against tightening supply conditions,” said Ryerson Holding Corp. COO Mike Burbach.

with a deadline of under 10 months, kingspan panels allowed for quick installation.

with a deadline of under 10 months, kingspan panels allowed for quick installation.

ersatility and ease of use are two of the highest attributes found in metals, so metals are often chosen for both the structural components and outer finishes of high-profile building projects.

Florida-based Kingspan Insulated Panels North America has developed a line of products that has gained favor with award-winning architects in the United States and Canada. Some recent projects for which Kingspan has supplied solutions include a professional soccer stadium and team training facility; a manufacturing facility for a maker of explosives used in oilfield applications; a multifunctional civic center; and a clean, bright and weatherproof East Coast boathouse.

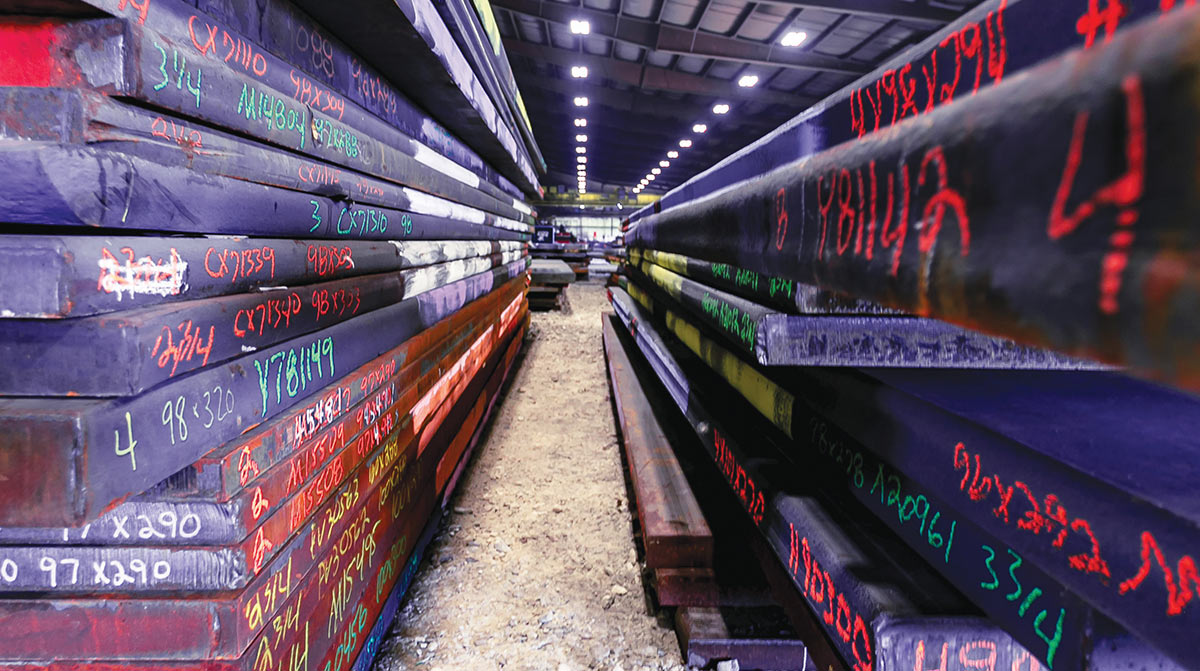

aunched in 2014 with what company President Jim Stevenson calls “the dirty dozen” employees, Churchill Steel Plate now has 50 people working two shifts to keep up with demand.

“We are a very niche business,” says Stevenson. The distributor stocks carbon and alloy steel plate from 0.25 inch through 24 inches thick, but its specialty is processing material 6 inches thick and above. Services include high-definition plasma, flame and saw cutting, furnace treatment, grinding and ultrasonic testing.

When commodity markets move into territory rarely seen in years, a curious person wonders if and how participants have prepared for the unexpected.

outhern Steel Group is the largest privately owned steel supplier in Australia. It has been operating for more than 60 years and employs over 1,000 people nationwide.

“We hold a large inventory of plate, structural steel, merchant bar, pipe and rectangular hollow sections, giving us the capability to manage small- to large-scale projects and long-term supply,” says the company’s project manager, Kerrie-Anne Gatt.

“Despite its size, the Southern Steel Group is still a family business that makes excellent customer service its absolute top priority. Our agility and can-do attitude allow us to move fast to deliver accurate, just-in-time solutions to construction, engineering and manufacturing challenges,” Gatt says.

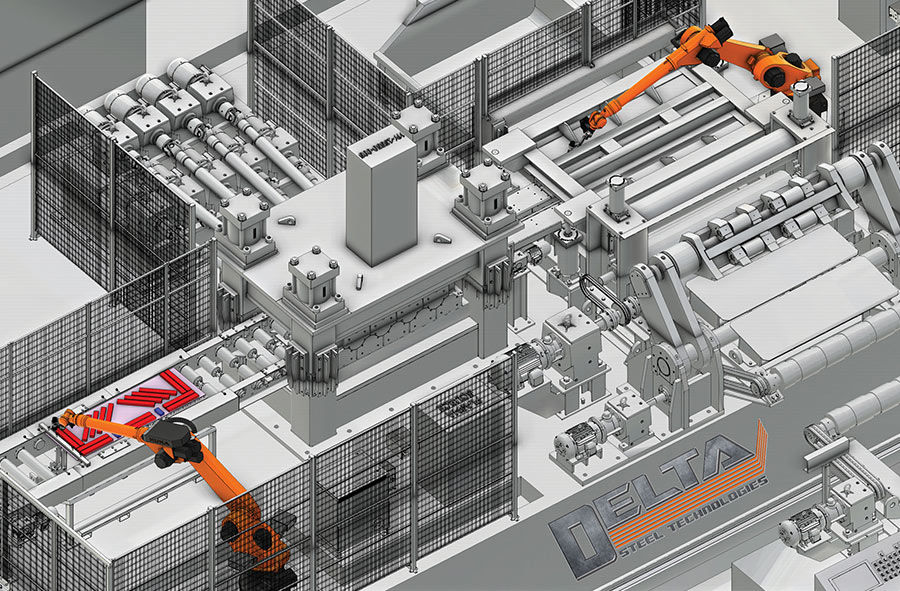

or K&S Machinery Corp., Linden, New Jersey, success can be attributed to a long standing practice of getting to know the customer in order to identify their very specific needs, and being able to translate that into a component or entire processing line that meets or exceeds expectations.

All of the equipment it builds is custom, meaning that it is rare for a duplicate piece of equipment to go through its manufacturing plant.

One of K&S Machinery’s customers had a dilemma. The customer was slitting light-gauge product 60 inches wide and when they ran heavy-gauge, narrow-width material, the arbors deflected due to the increased load.

3A Composites USA Inc.

721 Jetton Street, Ste. 325, Davidson, NC 28036

800/626-3365

3acompositesusa.com

Akzo Nobel Coatings Inc.

1313 Windsor Ave., Columbus, OH 43211

614/294-3361, fax: 614/421-4368

akzonobel.com/ccna

American Metals–USG Interiors

Flack Global Metals

Gulfport, MS 39503-4662

228/575-7733, fax: 228/575-7759

goldinmetals.com

Old Country Mill Work

5855 Hooper Ave., Los Angeles, CA 90001

323/234-2940, fax: 323/234-6564

ocmcoil.com

PPG Industries Inc.

Ply Gem Inc.

Precoat Metals

The Shepherd Color Co.

Cincinnati, OH 45246

513/874-0714, fax: 513/874-5061

shepherdcolor.com

uring a second-quarter earnings call, President and CEO Leon Topalian emphasized that Nucor Corp. is focused on becoming the world’s safest steel company. “We continue to perform well on the safety front, as we look to make 2021 our safest year ever, besting our record set just last year,” Topalian said on the July 22 call.

Despite the challenges presented by the pandemic in 2020, Nucor Tubular Products recorded a profitable year, and the company is on pace for an even better year in 2021. That success is due in no small part to its focus on safety.

Parts, ASAP

Waterjet machines help fabricators get back to business

By Lauren Duensing

s the world inches back toward normal, fabricators are finding their footing. Rashad Galloway, fabrication products manager at Texas-based MultiCam Inc., says that after reducing capacity—or even shutting down—to meet safety requirements, fabricators are “being bombarded with orders.”

FINISHING/DEBURRING

Osborn expanded its line of ATB Novoflex honing tools with additional abrasive grain sizes, abrasive types and diameters. The expanded offering now includes 185 new items and a total standard offering of 271 items. Available for hole diameters ranging from 0.196 inch to 8 inch, Osborn’s small-diameter ATB Novoflex tools are designed with round, abrasive silicon carbide beads fastened to the end of flexible nylon filaments providing an edge break not possible with conventional honing stones. These self-centering tools conform to the bore surface resulting in a consistent, even surface finish over the life of the tool. In addition, the long brush length is ideal for reaching into holes and crevices where other brushes cannot.

Osborn, Richmond, Indiana, 765/965-5333, osborn.com.

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.modernmetals.com

312/654-2309, Fax: 312/654-2323

mdalexander@modernmetals.com

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@modernmetals.com

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Oklahoma, Pennsylvania, South Carolina, South Dakota, Tennessee, Texas

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@modernmetals.com

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@modernmetals.com

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@modernmetals.com

Modern Metals® (ISSN 0026-8127, USPS 357-640) AUGUST 2021, Vol. 77, No. 8 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Modern Metals® (ISSN 0026-8127, USPS 357-640) AUGUST 2021, Vol. 77, No. 8 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.