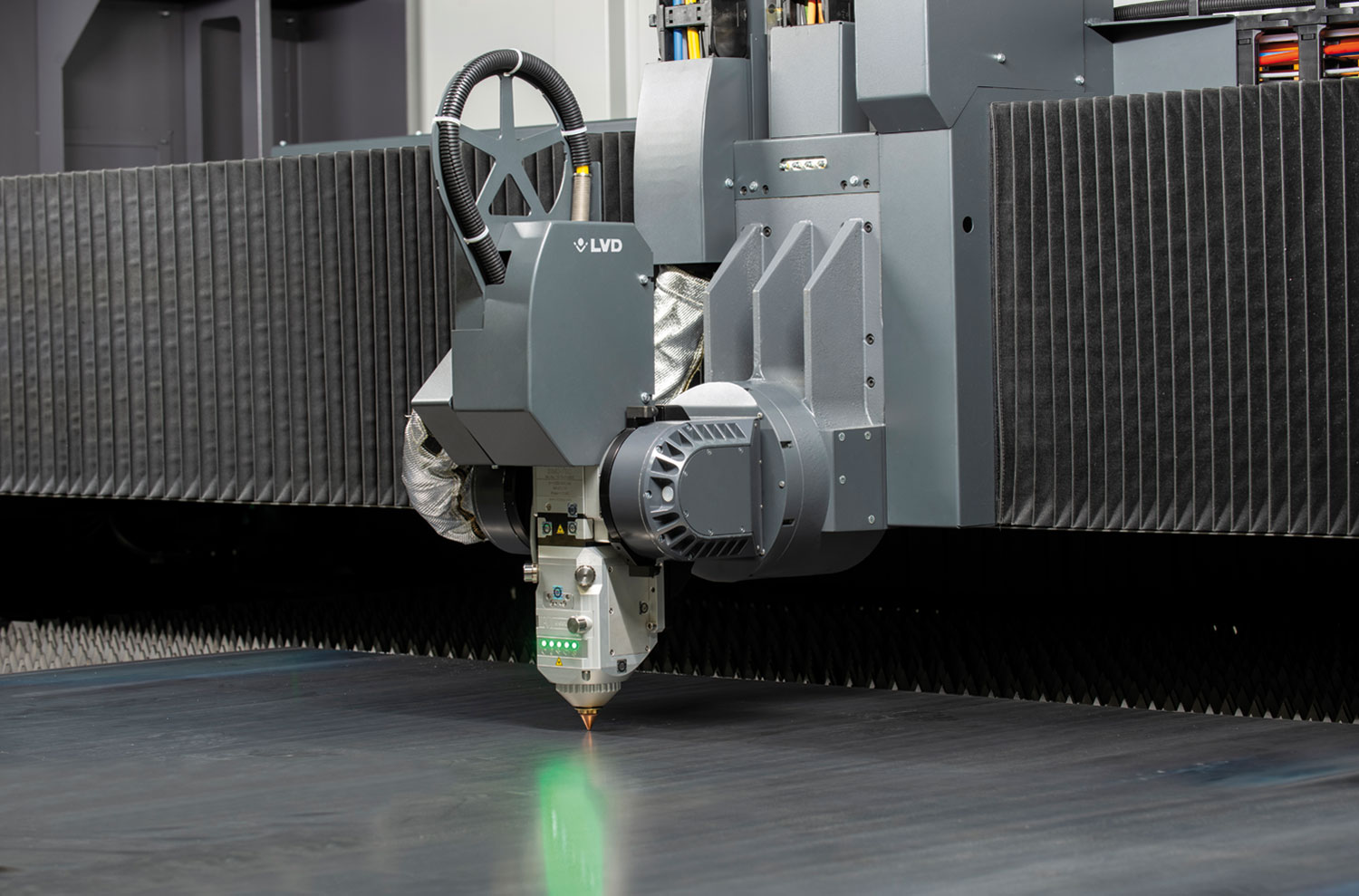

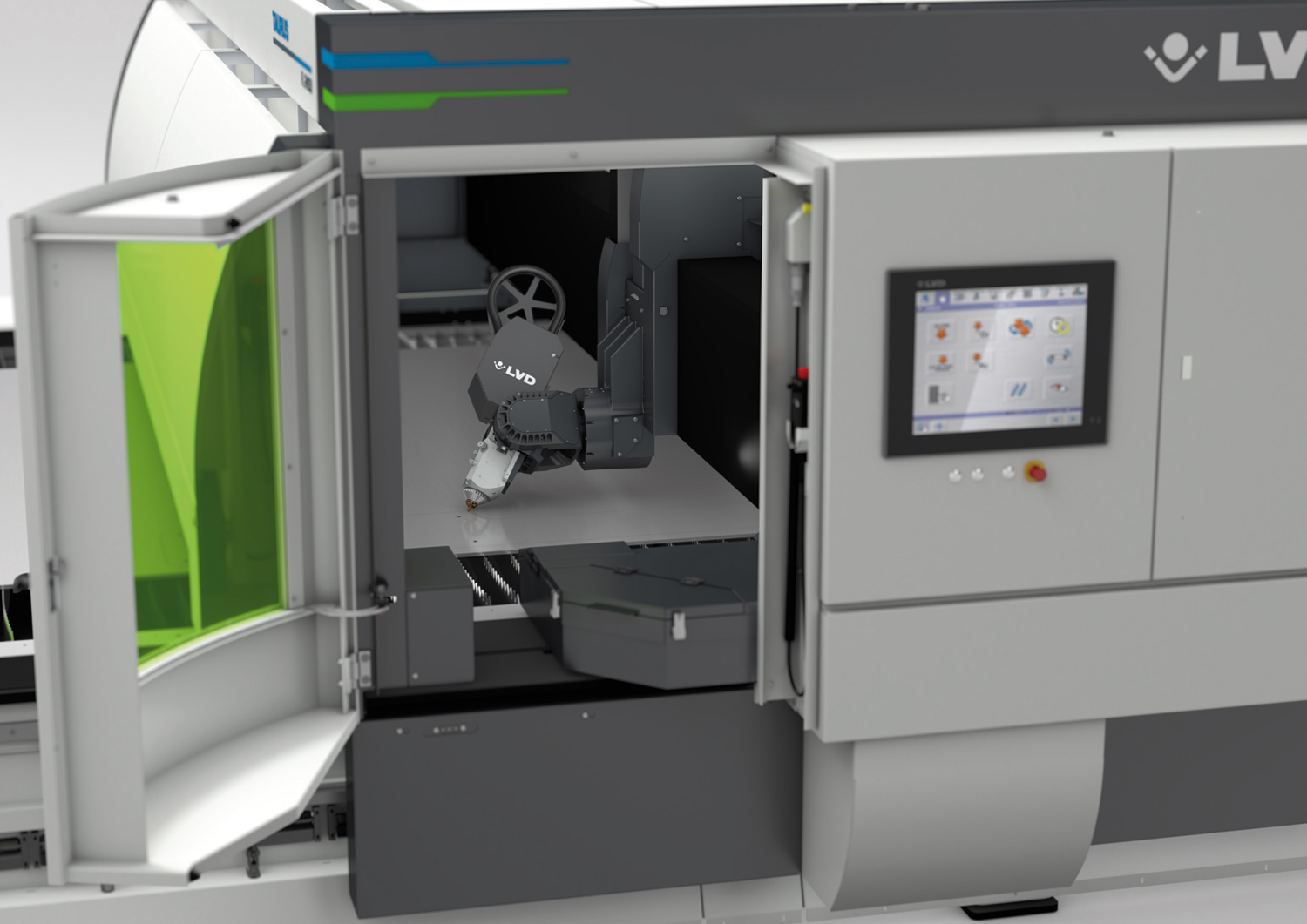

LVD’s Taurus is a large-format gantry-style fiber laser machine engineered for extra-large cutting capacity.

XXL

Large-format fiber laser has big cutting capacity that helps fabricator prioritize parts

cala, Florida-based contract manufacturer OFAB Inc., has been humming along since 1984 and has served the fire and emergency vehicle industries since 1988, providing services from laser cutting to finishing. OFAB also fabricates and machines parts for the mining, engine distribution, military and agriculture sectors.

“When we first started with laser cutting, they were rare machines,” says Mike Klinkroth, manufacturing manager. “Most cutting work was being done with plasma. We [owned] the first laser in our area, and selling laser work on a 5-foot by 10-foot cutting bed was pretty easy. Now, as lasers have become a mainstream piece of equipment, customers expect their parts will be cut with lasers.”

In a competitive market, fabricators are always striving to stand out. As capacity grew, Klinkroth says, “adding a fifth 5-foot by 10-foot cutting bed to our shop floor did not offer anything for our sales force to excite customers. We wanted to find an option that gave us a clear advantage and a new direction to discuss with customers, sort of a reset to the early days when laser cutting was new.”

So OFAB went big, installing an LVD Taurus 10 kW fiber laser cutting machine. This XXL-format machine has a modular design, with a bed length that begins at 32 feet and can be expanded in increments of 13 feet to a maximum of 137 feet. OFAB’s Taurus machine is 39 feet long.

The large cutting bed gives OFAB that “wow factor,” Klinkroth says. “It is our new avenue to approach customers and offer them something that others can’t.”

The flexibility of the large cutting bed is the key feature.

The flexibility of the large cutting bed is the key feature.

“To revise the shop floor for the new laser, we removed a 10-foot by 20-foot waterjet, moved a large section of material storage racks and an aluminum extrusion saw,” says Klinkroth. The waterjet was cutting large aluminum diamond plate truck panels, “a highly cosmetic application without a protective laser film. We sent a variety of this diamond plate to LVD for sample cutting and were pleased with the results. We felt confident the fiber pierce and cutting path was not going to damage the highly polished aluminum surface.”

After removing and reconfiguring the equipment, the OFAB team “measured the area and worked out a layout that kept the cutting bed open and cleared the roof support columns. After that, we brought the utilities in from the top—and ended up with a pretty clean installation. Once things were here on site, we actually saved some additional space.

“We were very impressed with Cedric Vlaeminck, who came over from Belgium to install the machine frame,” Klinkroth continues. “It was very interesting to watch three sea containers full of crates transform into the Taurus.”

Operators can access the laser’s entire working area for maintenance and part removal.

This ability to cut unattended allows OFAB to prioritize parts when customers need them on short notice. “It is a big deal when an ambulance or fire truck is out of service,” Klinkroth says. “The Taurus helps us lighten the impact of long-running jobs on the 5-foot by 10-foot fiber lasers which, in turn, allows us to address the regularly occurring, unplanned, emergency needs of our customers without as much disruption to our daily production goals.”

OFAB has expanded options for customers on oversized parts as a result of the Taurus’ large cutting bed and high-powered fiber laser. For example, MAC1 Products, which makes pumps and pump kits for firefighting applications, produces a fire truck water pump and, now, a pump module that is ready to be mounted on the fire truck chassis at the assembly line.

“This increases content for both companies dramatically and offers MAC1’s customers a great option to outsource a very complex component of the fire truck. The unit is built to their design and specifications—and working with OFAB eliminates all the hassle of fabrication, components, painting and assembly for them.”

OFAB, Ocala, Florida, 352/629-0040, ofab.net