COIL PROCESSING

Gentle treatment

ystems for the packaging of master coils, small coils, slit strips and sheets must meet differing requirements depending on the material. The finishing format as well as the number of pieces, size, thickness and possible coating also play a role. They may require, for example, particularly gentle handling of very sensitive surfaces, compliance with short set-up times or handling partial coils.

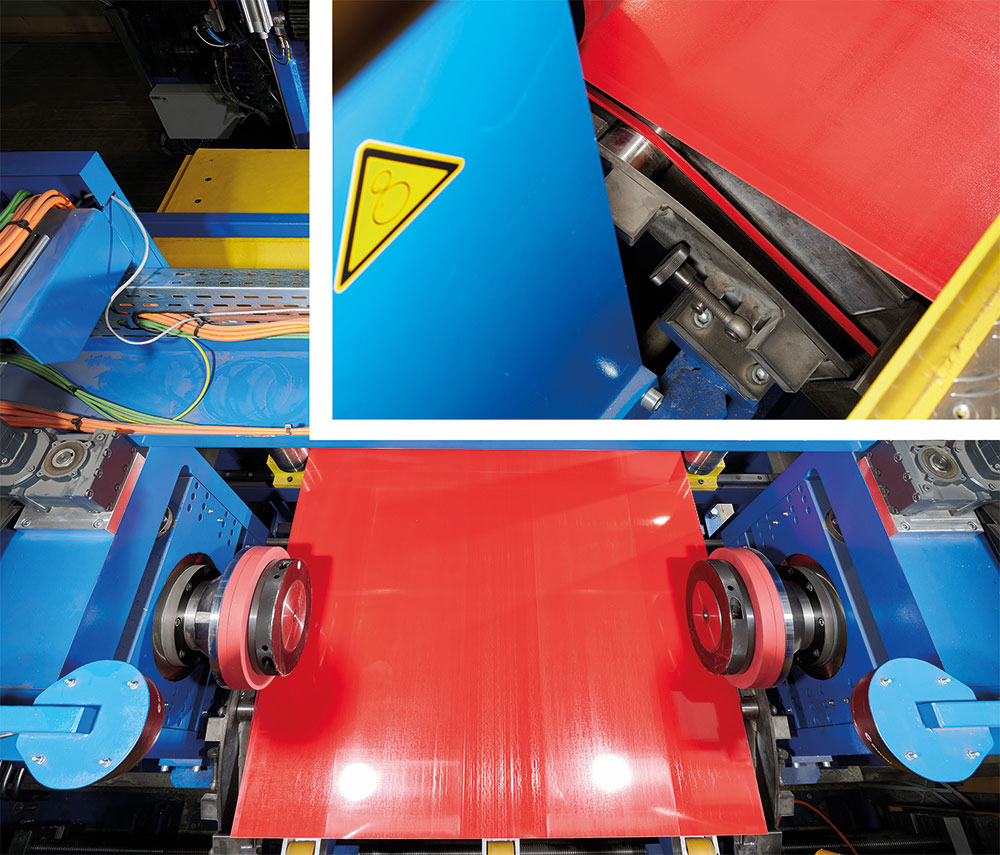

Fischer Stahl told its equipment supplier—Schnutz GmbH, a division of b+s group, that it was important to be able to offer small batch sizes processed from partial coils. Fischer chose the Schnutz line, in part, because it would be gentle in treating coated and pre-painted material surfaces. That is achieved with a special foiling system upstream and corresponding intermediate rollers within the leveling machines. A flying, high-precision slide shear also minimizes the cutting tolerance.

A flying, high-precision slide shear helps exceed customers’ cutting tolerances.

The shear control makes it possible to maintain low shape tolerances of the sheets.

The shear control makes it possible to maintain low shape tolerances of the sheets.

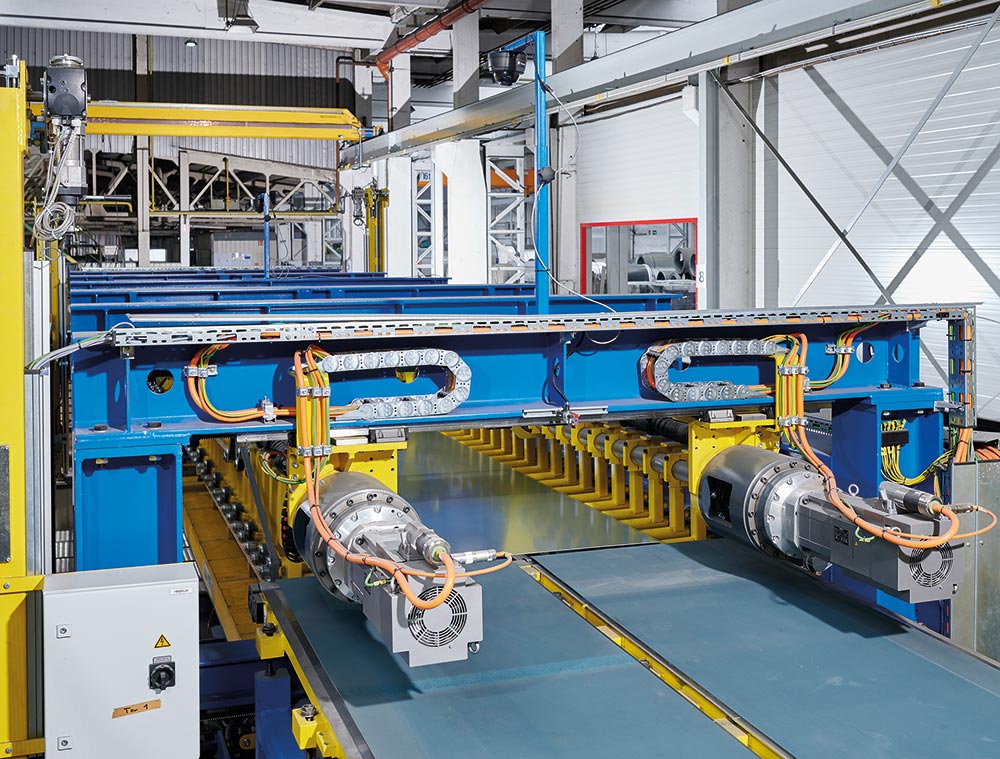

Decoil and rewind

The b+s trimming shear offers a burr-free cut; the cutting gap is adjusted by axially moving the upper cutter shaft. The line can trim edges on both sides of the coil up to 30 millimeters. The trim scrap is shredded by a special scrap cutter, which can be adjusted to the different material thicknesses by means of an electromotive cutting air adjustment.

The shear control, developed by b+s Automation GmbH, makes it possible to maintain low shape tolerances of the sheets at the specified belt speeds.

At the end of the line, a Burghardt+Schmidt swing-arm stacking machine ensures that sensitive material surfaces are treated gently through to the final processing steps. It features two stacking positions, which can also be used together for long sheets. All stops in the stacking area are moved electrically so that no damage to the belt edges occurs during destacking.

When developing the system, b+s group felt it was important to be readily responsive to machine operators. Should problems ever arise, the automation built into the line provides b+s technicians full remote access to Fischer Stahl’s line for consultation and troubleshooting.

Schnutz GmbH, Siegen, Germany, schnutz.com.

Wolfgang Fischer Stahl GmbH, Netphen, Germany, fischerstahl.de.