New Products

WATERJET

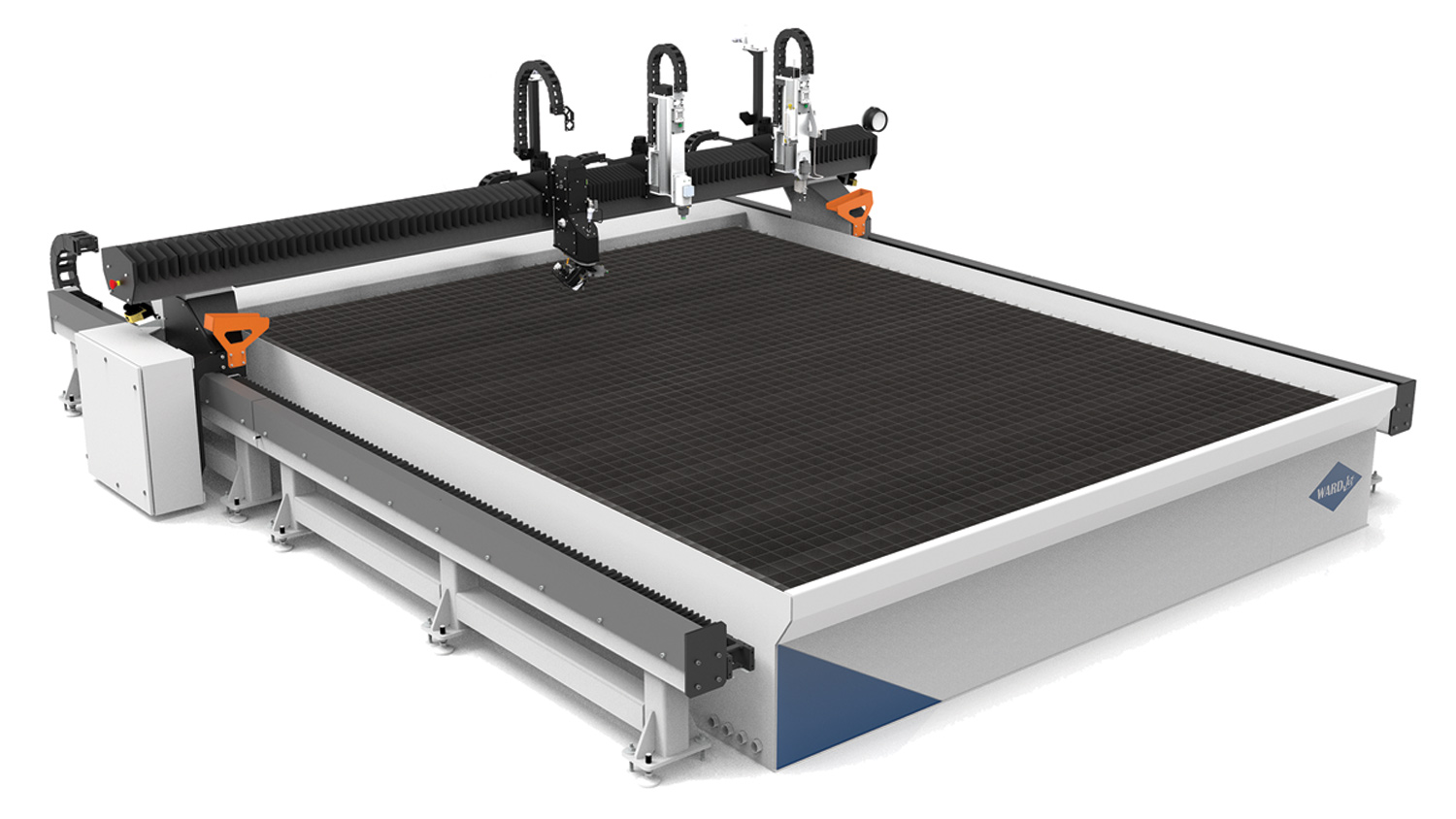

Cutting multiple sheets made easy

The M-Series is a high-speed, high-acceleration, large-format waterjet solution for large and multiple sheet production. Designed for industry standard sheet sizes, the waterjet maximizes access to all sides of the cutting area. It features WARDJet’s touch control software. A hardened helical rack-and-pinion drive allows up to 1400 ipm high accelerations while maintaining accuracy.

WARDJet Tailored Waterjet Solutions, Tallmadge, Ohio, 330/677-9100, wardjet.com.

ROUTING

High-performance metal cutting

The Metalworker was designed for end users looking to process small to large-sized sheets of material including aluminum, copper, zinc, metal composite and more. A rigid frame coupled with a stress-relieved gantry reduces tool motor vibrations and provides improved edge quality. The interface drives all machine tasks and is designed to optimize operations. Users can perform tool changes, set up work offsets, call up new files or optimize cut speeds.

AXYZ Tailored Router Solutions, Burlington, Ontario, 800/361-3408, axyz.com.

PLASMA CUTTING

cartridge combines tasks

Three new air plasma systems called Powermax SYNC feature built-in intelligence and a single-piece cartridge consumable. Powermax SYNC and its SmartSYNC torch replaces the traditional five-piece consumable stack-up with a single color-coded cartridge. Technology embedded in each cartridge automatically sets the correct amperage, air pressure and operating mode and lets operators know when a new cartridge is needed. Additionally, controls on the SmartSYNC torch allow operators to adjust the amperage and change the cartridge without returning to the power supply.

Hypertherm, Hanover, New Hampshire, 800/737-2978, hypertherm.com.

MATERIAL HANDLING

Combilift launches new electric model Lift truck

In line with the growing demand for electric-powered equipment, the Combi-XLE multidirectional forklift with up to 5-ton lift capacity combines emission-free operation with performance. Combi-XLE helps clients achieve their environmental goals with its versatile “3 forklifts in 1” models, which work inside and out, reducing fleet size and thereby the carbon footprint. Combilift products allow increased storage capacity without expanding footprint, resulting in lower energy consumption and associated costs such as heating, lighting and maintenance.

Combilift USA, Greensboro, North Carolina, 877/266-2456, combilift.com.

ABRASIVES

Polishing discs offer quick, easy finishes

The Norton Rapid Polish felt polishing discs feature premium quality, press-hardened, thick felt material for quickly and easily creating exceptionally smooth surfaces with single digit Ra and mirror finish shine. At 2,000 to 3,000 RPM, Rapid Polish discs stay cool and do not produce vibration, ensuring optimal final finishes. Rapid Polish Discs are available in both depressed center discs with a 5/8 in.-11 in. or 7/8 in. holes, and in 2 in. or 3 in. TR (Type III) quick-change discs.

Saint | Gobain Abrasives, Worcester, Massachusetts, 508/795-5000, nortonabrasives.com.

LASER TECHNOLOGY

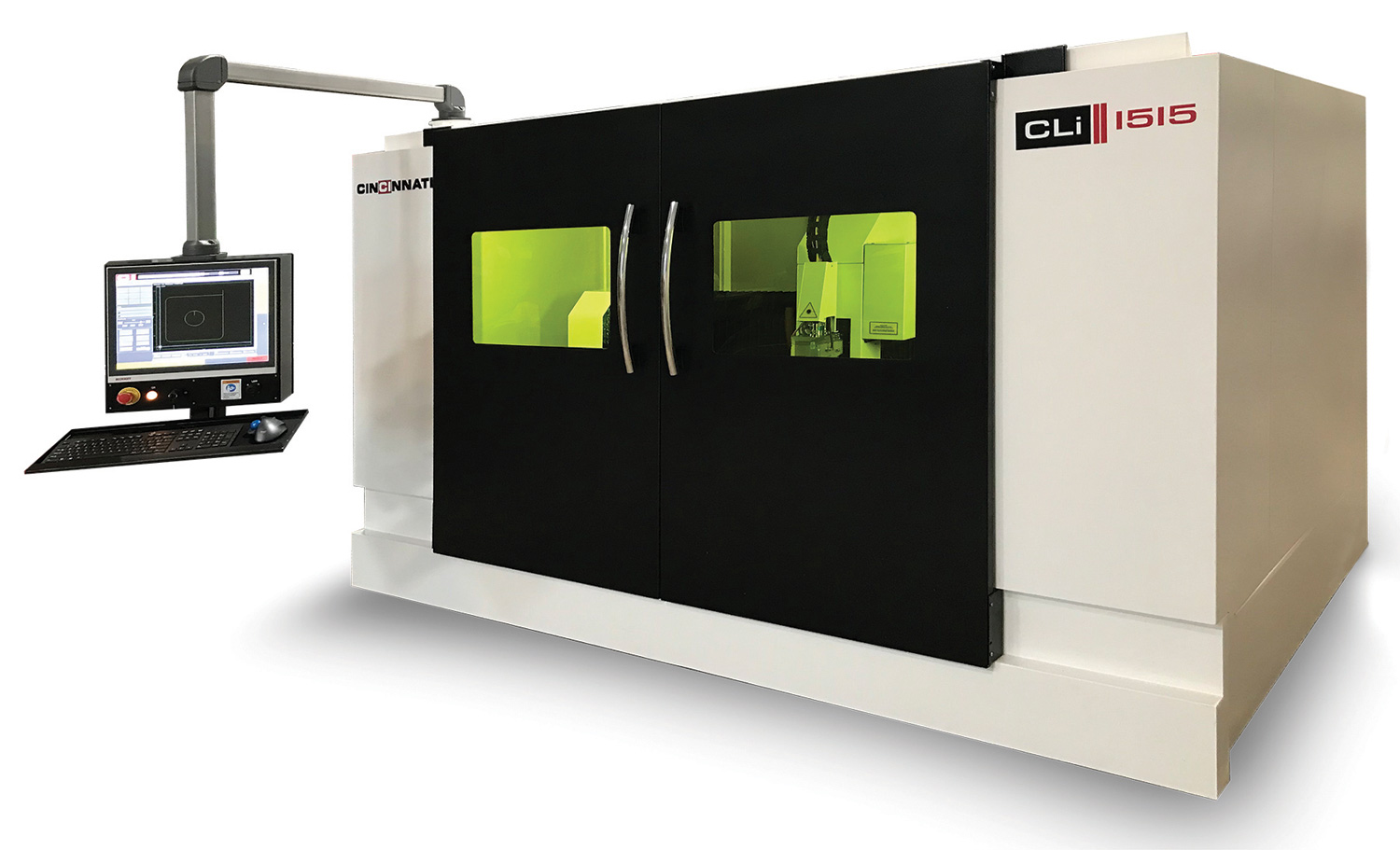

Fiber laser has compact footprint

The CLi fiber laser users no longer need to count on contract manufacturing partners and mysterious lead times if they need laser cutting done. The lowercase i in CLi stands for introductory, meaning it’s an ideal starting laser for shops that want to make parts rather than outsource. The CLi packs user friendliness and easy operability due to its HMI control and dual-screen Windows-based interface. The 5 ft. by 5 ft. table is packed into an economical 10 ft.-by-11 ft. footprint, meaning it can fit just about anywhere on a shop floor.

Cincinnati Inc., Harrison, Ohio, 513/367-7100, e-ci.com.