eople make all the difference in organizations. And that is especially true for companies that persevere. Future Metals is celebrating its 50th anniversary in 2021, and it would have not braved the vicissitudes of market cycles without the right people to create, maintain and grow the company.

Founders John Porfidio, president; Charles Woodard, vice president of finance; John Ferrara, vice president of sales; and Bill Menze, vice president of warehouse operations, had all worked together at Tube Distributors before becoming entrepreneurs.

Beth Erickson was hired at the tender age of 15, working part time after school as a filing clerk and telex operator. “There were no computers back then, other than the punch card data processing equipment we used for billing,” she recalls. Erickson joined the company full time upon graduating high school in 1979.

Erickson appreciates her colleagues, those who “have been instrumental in the success of this business. Our product offerings have continued to mature and grow,” including through acquisitions. “We now have 11 divisions worldwide serving the global aerospace industry.”

After 44 years, Erickson still wears many hats: “I am a salesperson, a customer service advocate, a program manager, a key account manager. It does not matter what title I go by—the learning never stops.”

That incident told Ball all he needed to know about the company leadership’s willingness to treat employees as family members.

Along the way, “I met so many good people. I was in outside sales my entire career so I got to know so many customers—from San Diego to Maine, from Florida to Montana. I became friends with many customers. I traveled and saw things I would not have been able to see,” he says.

One of the Future Metals team’s greatest accomplishments was landing a contract as the sole supplier of tubing for a company that bends the material for aircraft engines. “We have kept that contract for 25 years.”

Challenges have included “rising and falling nickel prices, some mills going out of business, lead times stretching to 52 weeks. Another big challenge was 9/11 when nothing was flying for a while. But that was nothing compared to COVID-19, which is a great challenge for the travel industry. When planes are sitting in the desert, they don’t need sheet and tubing,” says Ball.

Since then, Future Metals “steadily kept on building customers and contracts enabling us, in 2004, to turn the office in The Netherlands into a service center for a smooth JIT supply into Airbus facilities and subcontractors throughout Europe.”

Future Metals’ EU operations also expanded to cover the maintenance, repair and overhaul market for aircraft “by shifting required materials into the European service centers for a same-day delivery for airliners and repair centers’ aircraft-on-ground requirements.”

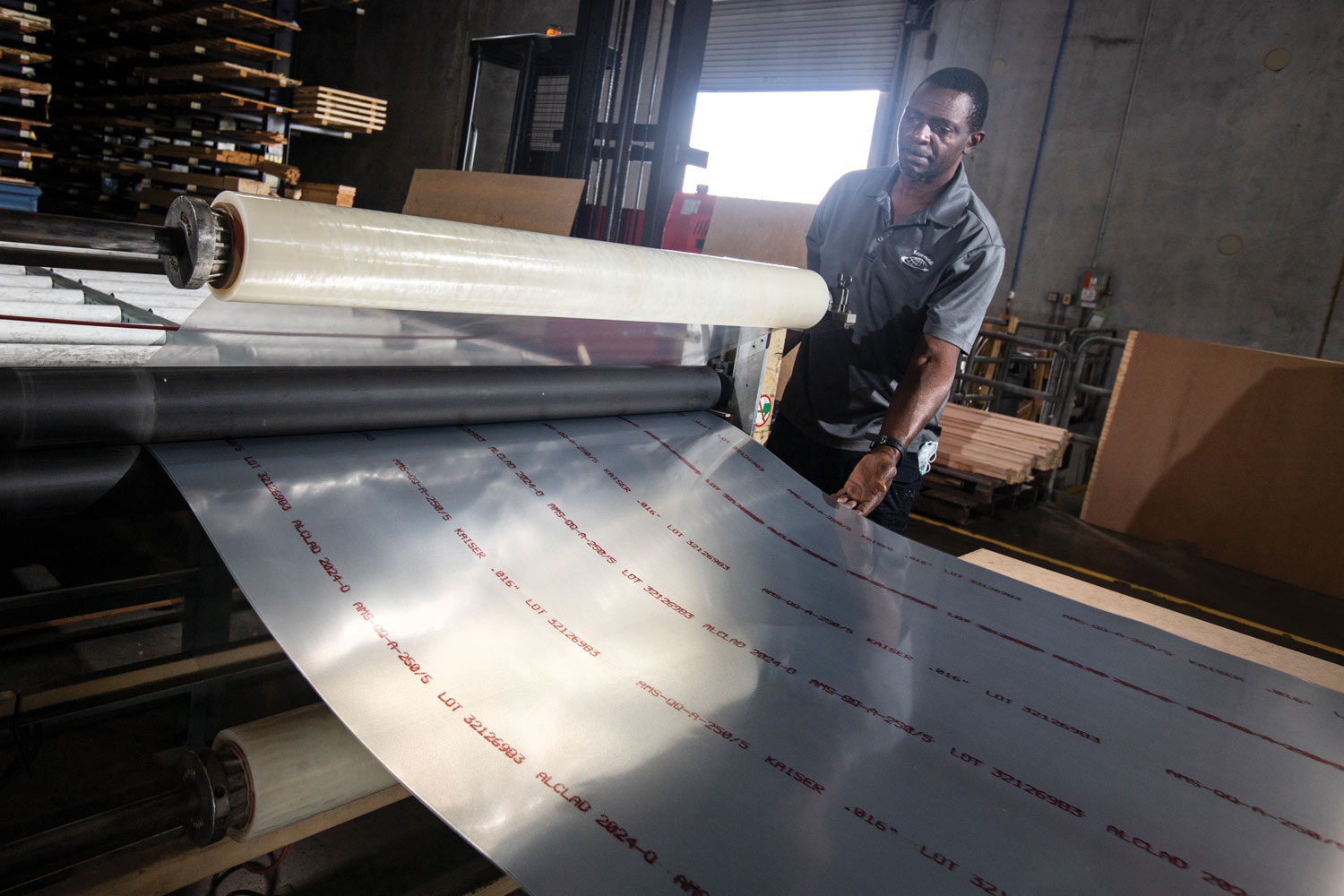

This industry works hard to make sure the metal is always there, it’s quality, it’s always on time.

This industry works hard to make sure the metal is always there, it’s quality, it’s always on time.

Future Metals strategically brings supplies, service and added value to customers around the world, “allowing them to reduce inventory on hand and focus on their core business,” van der Griend explains.

Now that Ramos is in raw material distribution, it’s a chance to “peel back the onion. It gives you a good understanding for the entire process—working with raw materials, working with mills, seeing products installed in engines and seeing an F-35 fly.”

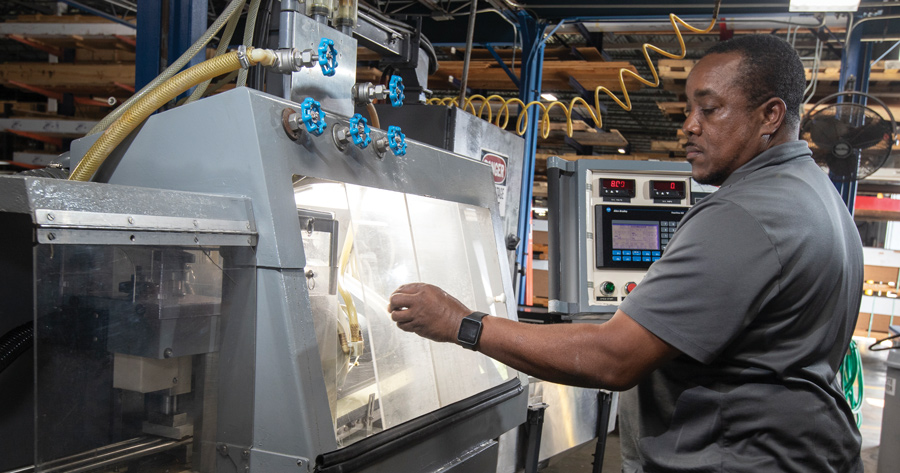

“If we send bad material, we have to address nonconformance and provide a plan. OEMs will also ask us for performance improvements, greater efficiency, all to save the customer money. We have to show improvement and submit projects to them on a regular basis,” he says.

“These are standard asks,” he continues. “When you work with a Lockheed Martin, they are very selective about suppliers. The expectations are very high. When we were named an Elite Supplier, that means there were no quality defects, we were 100 percent on time, we acknowledged every document and submitted continuous improvement projects. You are essentially flawless for a given time period” to achieve the ranking.

Working on the supply side for the past year “has been eye opening,” he says. “When building an F-35, you don’t ask where this tubing comes from. You are worried about engines, wings, helmets, cockpits and fuselages. You don’t ask where the titanium is sourced. It’s just there.

“But that is the start of the process. You need to deliver raw material in a timely manner to start building an aircraft. Even if it is a small part, you need every part. The mission is so important.

“You aren’t just putting metal in a box and shipping it. It helps that our operators know where the product is going. The ownership, the pride in work is taken to the next level. This is an entire industry that works hard to make sure the metal is always there, it’s quality, it’s always on time.”

For perspective, says Ramos, “you can consider this Year 50 or Year 1. You take the lessons from the past, from a legacy organization, but you also plan for the next 50 years. Shaping that now is a big responsibility.”