abrication machinery needs to be tough to cut parts day in and day out, and, when well maintained, it has a long useful life. But technology is always advancing and, sometimes, replacing old equipment can result in big gains.

In 2017, the York, Pennsylvania, warehouse of Kloeckner Metals, one of the largest metals manufacturing, supply and service companies in North America, was evaluating its laser-cutting machines. At the time, it had two CO2 machines that were falling short both in cutting thicker material and in speed. One of these lasers was 15 years old; the other had been worked for 12 years.

“They were in need of some fairly costly repairs, and it didn’t make sense to repair them,” says David Schott, regional fabrication manager for Kloeckner. “They were also quite a bit slower than current laser technology.”

kloeckner metals

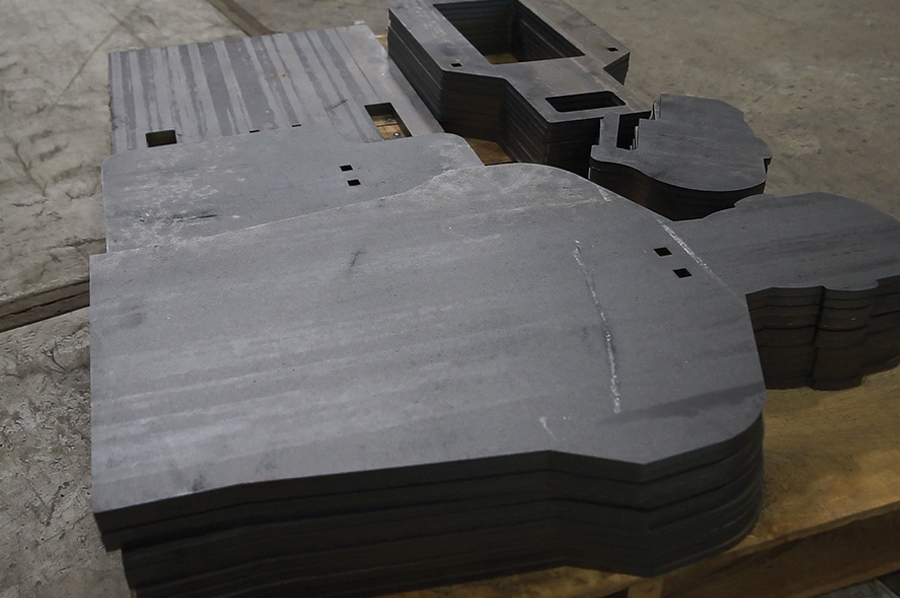

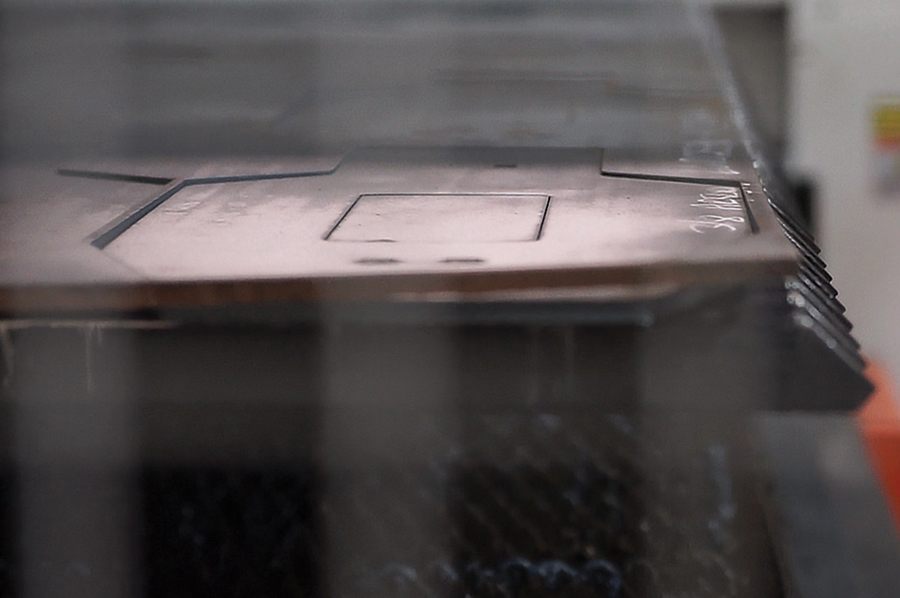

Schott says the laser can cut carbon and stainless steel up to 1 inch thick, and sensors in the multi-function torch monitor piercing and cutting operations. The result is improved throughput and part quality. If an anomaly is detected, the machine either adjusts or pauses the operation to automatically achieve efficient cutting conditions.

“Because of some of the automated cutting–related options (nozzle changing, focus, etc.), it creates a good cut with little operator intervention,” Schott says. “This lets us quickly change from different materials and different thicknesses. It also allows the operator to focus on keeping the machine cutting parts instead of adjusting the machine to cut efficiently.”

Schott says the laser’s capabilities benefit both Kloeckner and its customers. Processing parts more efficiently increases throughput and reduces the cost per part. In addition, the ability to hold tight tolerances mean parts fit together better and secondary processes run more smoothly.

And, with the Extensible Manufacturing Cell’s modular approach, which can flex to accommodate the laser configuration as needs change, Kloeckner is not only cutting faster in the present but also prepared for growth in the future.

Mazak Optonics Corp., Elgin, Illinois, 847/252-4500, www.mazakoptonics.com.