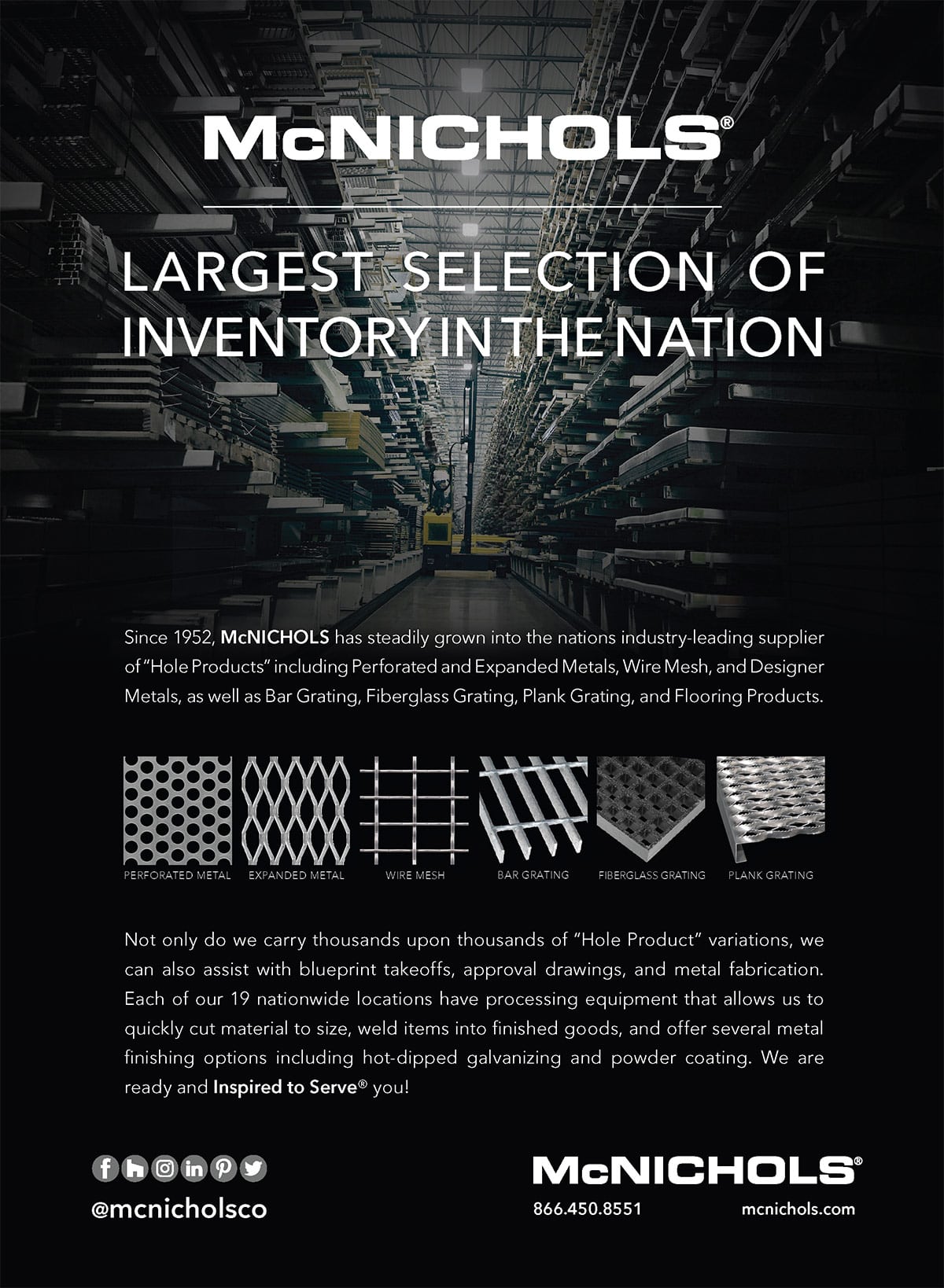

We’re relentlessly committed to passionate customer service, offering versatile operations and the industries’ most expansive national footprint.

Come ride the VORTEQ wave of momentum for your coil coating needs! Let’s get started at vorteqcoil.com

Features

ow.ly/Mi3030qhKm3

@GreenCarCongres

he U.S. Air Force released a $169 billion budget proposal Feb. 10. A large portion of those funds are focused on people and sustaining readiness.

At the heart of the Department of the Air Force’s strategy for winning conflicts is creating a resilient battle network that connects ships, ground forces, planes and satellites, allowing them to fight together at speeds far surpassing any adversary.

The 2021 budget provides funds for a rapid experimentation, prototyping and development effort supporting the Joint Staff’s initiative to connect every sensor and shooter in land, sea, air, space and cyber.

The budget proposal also addresses what the service calls “logistics under attack,” ensuring equipment, personnel and supplies are available when and where they are needed to sustain high-tempo actions in combat operations. Research and development funds will total $26.9 billion in fiscal 2021.

any proven efficiencies in manufacturing have come from leaders in the metal stamping industry. They have a keen skill set in areas such as pricing, project management, quality and performance of their vendor base, notes Tom Lytle, vice president of Delta Industrial.

A: Delta Industrial has been providing custom press pit foundations for more than 25 years. We have always positioned ourselves as design-build specialists and have continued to grow in no small part due to our diversity of knowledge in all areas of construction.

Our project management process hasn’t changed over the years: we evaluate every aspect of the job—from analyzing soil conditions to ensuring we have appropriate staffing—before the job begins. The only thing that is different is that the press foundations we do have grown in scope.

he first time I ever cut anything with a band saw blade was at a public-use shop, where I had a monthly membership. I thought I was there to invent the next industry-leading CNC milling machine. In retrospect, however, I was doing a lot of learning by trial and error.

“There must be a formula that will allow me to cut through a piece of metal faster than this,” I thought, as I waited about an hour for the rickety horizontal band saw to trudge its way through a piece of 4-inch-round scrap aluminum.

ESAB Welding & Cutting Products, Annapolis Junction, Maryland, finalized the transition to the Exaton brand name for all welding filler metals, which were part of its 2018 acquisition of Sandvik Welding Consumables. For stainless consumables, the Sandvik name has been replaced with the Exaton followed by the AWS/ASME classification of the product. For example, Sandvik 317L is now Exaton 317L. Its nickel-based consumables, previously sold under the Sandvik and Sanicro names, are renamed, too—for example, Sandvik NiCrMo-3 is now Exaton NiCrMo-3.

The Aluminum Association chose Tom Dobbins as president and CEO. Dobbins previously spent 13 years as the head of the American Composites Manufacturers Association. Dobbins is a recent member of the board of directors of the National Association of Manufacturers Council of Manufacturing Associations. He is also a past chair of American Society of Association Executives Public Policy Committee and Lobby Task Force.

Michelle Pearson-Casey has joined Olympic Steel Inc., Cleveland, as vice president for corporate communications and marketing. She is a former Olympic Steel employee, rejoining the company with nearly 16 years of prior service and close to 20 years of experience in communications, change management and human resources.

Troy Kreter has joined Central Tube and Bar, Conway, Arkansas, as territory manager for the Midwest region. He has over 20 years of fabricated tubing sales experience.

Emuge Corp. appointed Scott Lowe as national accounts manager for the U.S. and Canada. Lowe previously spent over 13 years at Kennametal, most recently as sales manager for nearly six years and before that as senior applications engineer.

HGG Profiling Equipment, Medina, Ohio, appointed Michelle Cooper as customer account manager for the Americas. She supports HGG U.S. regional managers with quotations, purchase order processing and invoicing and supports HGG customers with inventory management and parts acquisitions.

After seven years working at Bystronic Inc, Elgin, Illinois, and a career in sheet metal fabrication spanning over five decades, Paul LeTang, press brake product manager and bending guru, has retired. LeTang has been a resource for bending in the sheet metal fabrication industry for years.

Gordon Kushner, senior vice president, general counsel and secretary for ECI Software Solutions, was recognized as a 2020 Top 50 Corporate Counsel Award winner at the OnConferences Icon Awards program. The Top 50 list is based on peer recognition of performance, impact and contributions to the legal community.

MC Machinery, Elk Grove, Illinois, appointed Shannon Morris as a regional sales representative for North/Central Texas and a portion of East Texas; and chose Mark Kauffman as regional sales representative for Southern California, Nevada and New Mexico.

For heavy-duty cutting applications, Steelmax Cermet-tipped saw blades offer superior wear and heat resistance for long cutting life. These blades feature a super-thin kerf for fast, efficient cutting and laser-cut stabilizer slots that reduce noise and vibration. Steelmax’s proprietary blade geometry, incorporating wide and shallow tooth pockets, combined with its Triple Chip Grind, provide speed and durability for clean, burr-free cuts in even the hardest alloys.

Steelmax Tools LLC, Centennial, Colorado, 303/690-9146, www.steelmax.com.

Multiple rounds of testing, prototyping, and optimization with professionals in the field led Simonds Saw to develop four new bi-metal bandsaw blades that are perform across various functions. The new blades were designed with the specialized depth to meet all metal cutting applications, including production cutting, structural steel and tough exotic alloys.

Simonds Saw, Fitchburg, Massachusetts, 978/424-0100, www.simondssaw.com.

.S. citizens are largely trusting of our military, and for good reasons. Service members sacrifice to protect Americans and American interests at home and abroad. What we rarely think about is what it takes to keep the planes flying, in a timely fashion, and how innovative ground crews, technicians and others have to be to achieve that.

A vital tool in the arsenal is, of course, the Air Force Research Laboratory (AFRL), whose mission is to lead “the discovery, development and integration of warfighting technologies for air, space and cyberspace forces.” Let’s take a look at how that works in the real world.

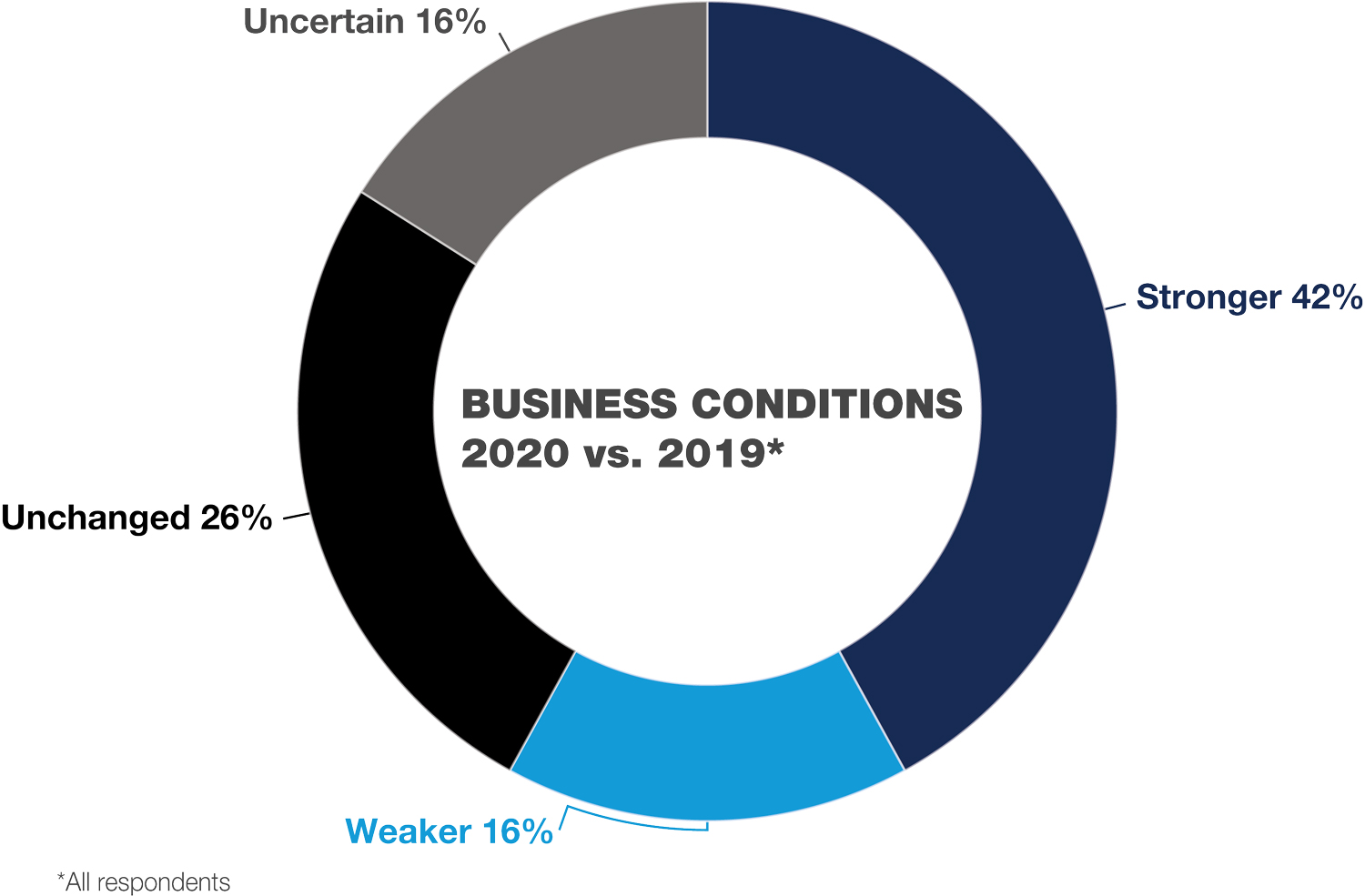

lections always call upon business leaders to consider whether the U.S. economy drives the results or vice versa. “As with any debate, there is perception and then there is reality,” say the authors of a report from Ryerson, based on a survey it conducted of its customers.

Among the questions posed to customers for “The Metal Perspective” was whether they believed the presidential election would affect business. A thin majority (51 percent) said it will depend on the outcome.

ince its founding in 1951, the Copper and Brass Servicenter Association (CBSA) has been dedicated to the success of its members in the red metals industry. As the supply chain continues to evolve, so does the association.

To help ensure that the association is best serving its members, a Strategy Task Force forms every other year. This task force is chaired by the vice president of CBSA and comprises members of the CBSA board of directors.

Previous task force teams approached their work by having in-depth discussions with members about the products and services CBSA members provide, what they value and what they would like to see from CBSA.

800/423-6472, 781/933-8300, fax: 781/937-4469

www.admiralmetals.com

PRODUCTS: Brass, copper, bronze, beryllium copper, aluminum, stainless, rod, bar, sheet, plate, tube, custom and standard shapes

SERVICES: Sawing, grinding, waterjet cutting

401/736-2600, fax: 401/739-5797

www.wieland-metalservices.com

PRODUCTS: Architectural copper; copper and copper-alloy coil, strip, sheet, bar, rod, wire, tubing and nails; copper roofing sheet and flashing rolls; lead-coated copper; freedom gray; brass sheet, coil and wire; stainless steel sheet and coil; mill-finish aluminum coil, sheet and strip; painted aluminum sheet and coil; anodized aluminum sheet and coil; aluminum foil; painted carbon steel sheet and coil; and aluminum composite panels.

SERVICES: Slitting, leveling and cut-to-length, blanking, shearing, traverse winding, tinning, coating, cleaning, edging, make-and-hold programs, and inventory management.

A premier value-added metal service center

For almost 100 years, Wieland Metal Services, formerly A.J. Oster, has been a processor and distributor of copper and copper alloy sheet, strip, and foil, aluminum sheet, and coated aluminum products.

864/227-5262, fax: 864/227-5206

www.gindrecopper.com

PRODUCTS: Bar, shapes, strip, rod, wire

800/431-7460, 989/983-2800, fax: 989/983-4530

www.h-htube.com

PRODUCTS: Tube, hydroform, impact extrusion

SERVICES: Annealing, drilling, polishing, roll forming, tapping, beading, bending, flaring, precision cutting, vibratory cleaning

abrication machinery needs to be tough to cut parts day in and day out, and, when well maintained, it has a long useful life. But technology is always advancing and, sometimes, replacing old equipment can result in big gains.

In 2017, the York, Pennsylvania, warehouse of Kloeckner Metals, one of the largest metals manufacturing, supply and service companies in North America, was evaluating its laser-cutting machines. At the time, it had two CO2 machines that were falling short both in cutting thicker material and in speed. One of these lasers was 15 years old; the other had been worked for 12 years.

“They were in need of some fairly costly repairs, and it didn’t make sense to repair them,” says David Schott, regional fabrication manager for Kloeckner. “They were also quite a bit slower than current laser technology.”

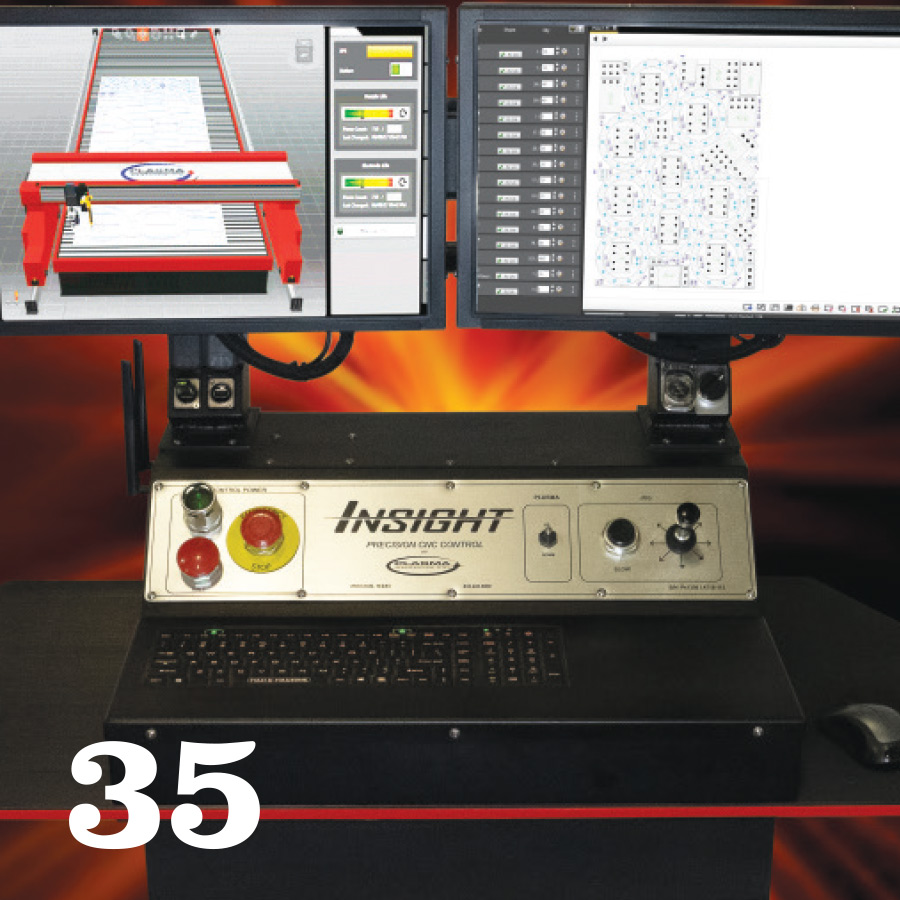

he team at Plasma Systems Inc. has more than 25 years’ experience in the plasma cutting industry. Working with a variety of customers has given the company a broad understanding of how to implement the right machine for the work environment, material specifications, available shop space, budget restrictions—and even staffing considerations.

Drawing on that experience, the Houston-based company recently developed and released its new InSight controller, which features an open architecture that combines tight security with the ability to add necessary tools to the system.

“The same old controllers have been around for years—but the cutting machine capabilities have changed,” says Richard Keeton, president of Plasma Systems. “Machines needed to be more precise, easier to use and adapt to a changing market quicker. Three years ago, we partnered with Atek Automation to produce a state-of-the-art controller,” and InSight was released after a year of thorough testing.

unning several bandsaw machines for 100 hours a week or more teaches you that even heavy-duty equipment can get strained at continuous levels of operation. You might want to specify new machines that deliver more power, more control, more precision, more speed and higher quality.

That was the trajectory taken by Sherwyn Greenfield, Iowa facilities manager for Rosenboom. The company—which has factories in Sheldon and Spirit Lake, Iowa; Bowling Green, Ohio; and China—manufactures custom hydraulic cylinders with typical bore sizes from 1 to 12 inches, typical stroke lengths up to 24 feet and operating pressures up to 10,000 psi. In business 45 years, Rosenboom employs 900 people in the United States.

“We build cylinders for OEMs; they are all custom designed and custom built,” Greenfield says. Cylinder lengths range from 6 inches to 40 feet. Applications for Rosenboom’s cylinders include agricultural equipment, construction equipment and aerial trucks.

partingshot

Advertiser Index

View Index

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.modernmetals.com

312/654-2309, Fax: 312/654-2323

mdalexander@modernmetals.com

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@modernmetals.com

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Oklahoma, Pennsylvania, South Carolina, South Dakota, Tennessee, Texas

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@modernmetals.com

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@modernmetals.com

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@modernmetals.com

Modern Metals® (ISSN 0026-8127, USPS 357-640) March 2020, Vol. 76, No. 3 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.