he smart factory trend continues to gain speed, especially in the way that software and sensors work together to provide real-time, actionable information on what’s happening with metalforming equipment.

Cincinnati Inc., which designs and sells press brakes and shears, laser cutting and additive manufacturing systems, is among those machine builders that have embraced and advanced Industry 4.0 on behalf of their North American clients.

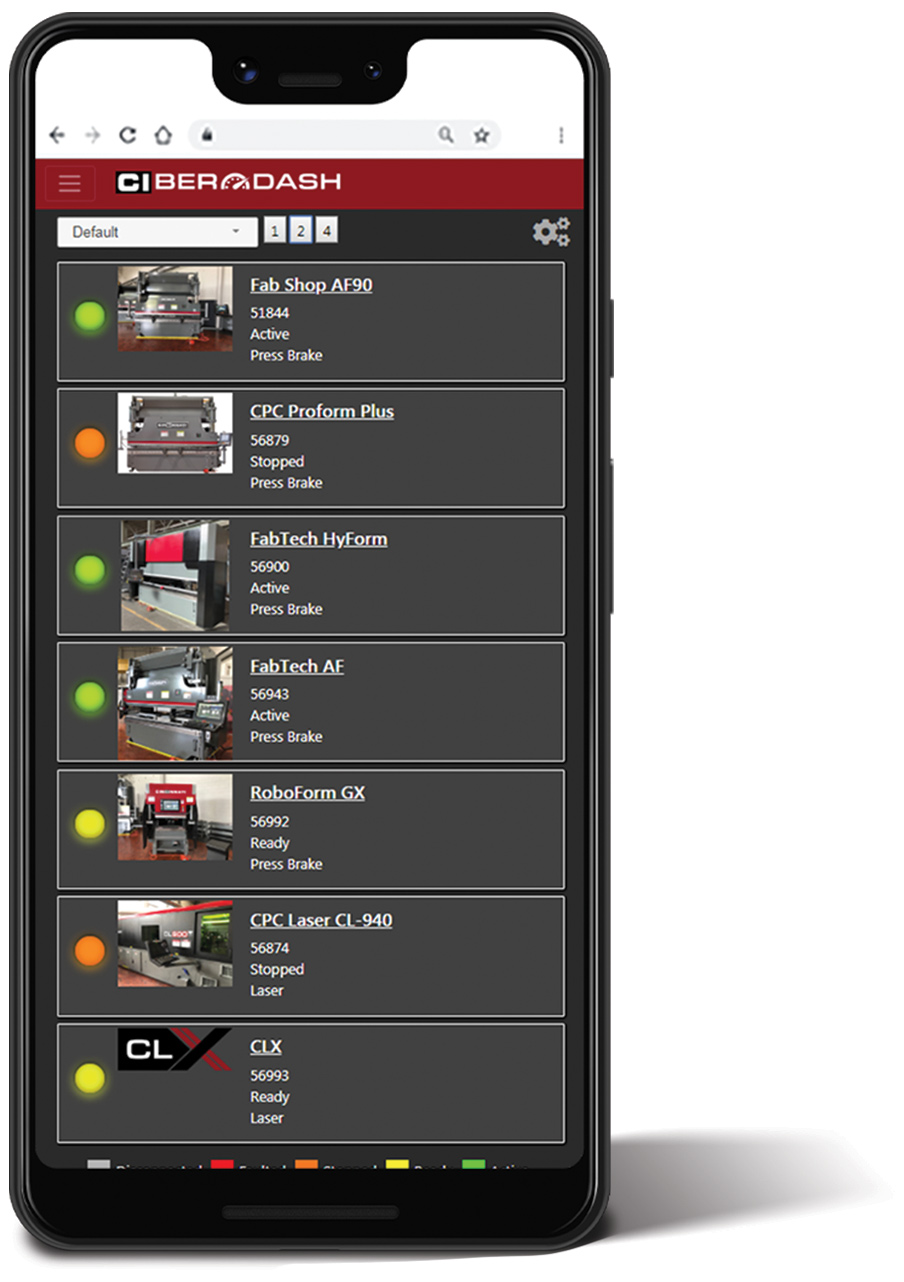

CIberDash, developed over the past two-plus years, allows real-time monitoring and daily logging of production data from Cincinnati equipment by connecting machines to the cloud through ethernet or a cellular transmitter.

CIberDash gives companies using Cincinnati products the ability to monitor performance remotely from a dashboard. On a smartphone, desktop or tablet, the digital tool displays each machine’s information and program details as well as the current 24-hour status of production. CIberDash also creates daily log files for each laser cutting table and press brake, and users can extract more than 50 separate categories from the logs, from product name to machine strokes to cycle time.

To instantly check the status of Cincinnati machines, a virtual StackLight graphic lives alongside each machine. Machine statuses range from “active” to “ready” to “stopped” to “faulted,” which lets managers and operators immediately identify machines that need attention.

“Are setups and changeovers taking too long? The operators might say no, but the shop floor manager says yes. With good data, you can now begin to make very thoughtful decisions in running your shop.

“We are trying to do this in a way that is not horrendously expensive,” Watson says. “A big problem about software for Industry 4.0 is customers cannot justify the cost-benefit ratio right off the bat.”

The Canadian government tried to address that, he says. “In Canada, companies can write off a portion of Industry 4.0 software,” which amounts to a 25 percent discount on the purchase. Most of the software that’s available “does a good job but it’s hard to write the check. As a result, we wanted to offer something economical that ties Cincinnati machines together.”

A manager can now look at the scoreboard, see what every machine is doing and know “instantly what to pay attention to,” Watson says. “Once you see the dashboard indicating a deficient work cell, you can go to the cell and talk to the operator about how to improve the situation.”

Users can see—by shift, by operator, by work cell—what the performance has been on a particular press brake. “You can collate information by part number. What differences are appearing when making these parts month over month?”

one customer said they hooked up 22 machines in one day. It highlights how simple this is.

one customer said they hooked up 22 machines in one day. It highlights how simple this is.

If very few error codes appear for tip touches, a follow-up question might be, “Maybe there is something else?” Finally, the operator acknowledges that the forklift driver is not delivering material fast enough and, as a result, he runs the laser dry until he gets the material. “So the tool is also a BS detector,” Watson says.

Performance can be improved, too. Sometimes the greatest improvement in performance has nothing to do with data; it may be simply the peer pressure from the large scoreboard on the shop floor. “We had a company that did a beta test with us but they didn’t want to do a whole lot of data analysis. They did want the scoreboard. After the first month, throughput went up 15 percent across 18 machines. That’s an advantage that equates to two or three work cells, which means they didn’t have to add machines” to keep up with the increased workload.

In response, Cincinnati offers API (application programming interface) calls, which Watson explains are “triggers that a software engineer can write” to import the necessary data from CI’s cloud into the third-party dashboard.

Users can also use OPC Unified Architecture, a machine-to-machine communication protocol for industrial automation. Using those methods, CIberDash becomes “friendly with all equipment makes and works well with third-party systems.”

The rate of adoption among customers that have sampled CIberDash “has been good. For the customers that bought it, it’s not sitting idle. It’s being used all the time. It is possible that a customer would buy it, and then leave it sitting on a shelf. But that’s not what’s happening,” Watson says.

“Trane has a lot of Cincinnati press brakes throughout their factories,” he says, and the company monitors detailed information such as how many strokes it takes to produce a part, how many parts are made per shift, whether a machine is on or off.

“This provides the equipment manager a quick look at what’s happening. The data is accessible, exportable. What do you do with it then? The answer varies,” Garbarino says. “It’s to be proactive—to maximize machine productivity and minimize downtime.”

It gives manufacturers a chance to react more quickly to situations. Multiple machines across multiple locations can be recorded in the dashboard and produce daily logs and reports, notes Garbarino.

Combined with other upgrades, CIberDash provides an opportunity for customers to extend the life of machines in some cases, he says. “In the case of Trane, they upgraded controls on older machines. So even if the iron is old, the controls are new and can be placed on the network, and those can be monitored, too.”

In other words, “instead of replacing a whole machine, for a fraction of the cost you can replace the controls. We have hundreds of customers that could perform similar upgrades. And CIberDash ties into that idea: better controls, better monitoring.”