hen cutting steel profiles and girders for construction applications, end users will usually seek a band saw blade that keeps its teeth intact, minimizes burr formation and is less susceptible to vibration. Mike Masters, chief technology officer for WIKUS Saw Technology Corp. in Addison, Illinois, says the company’s Proflex M42 bimetal blade does all of that. The M42 grade of high-speed steel for the blade has a flexible alloy backing to slow material fatigue.

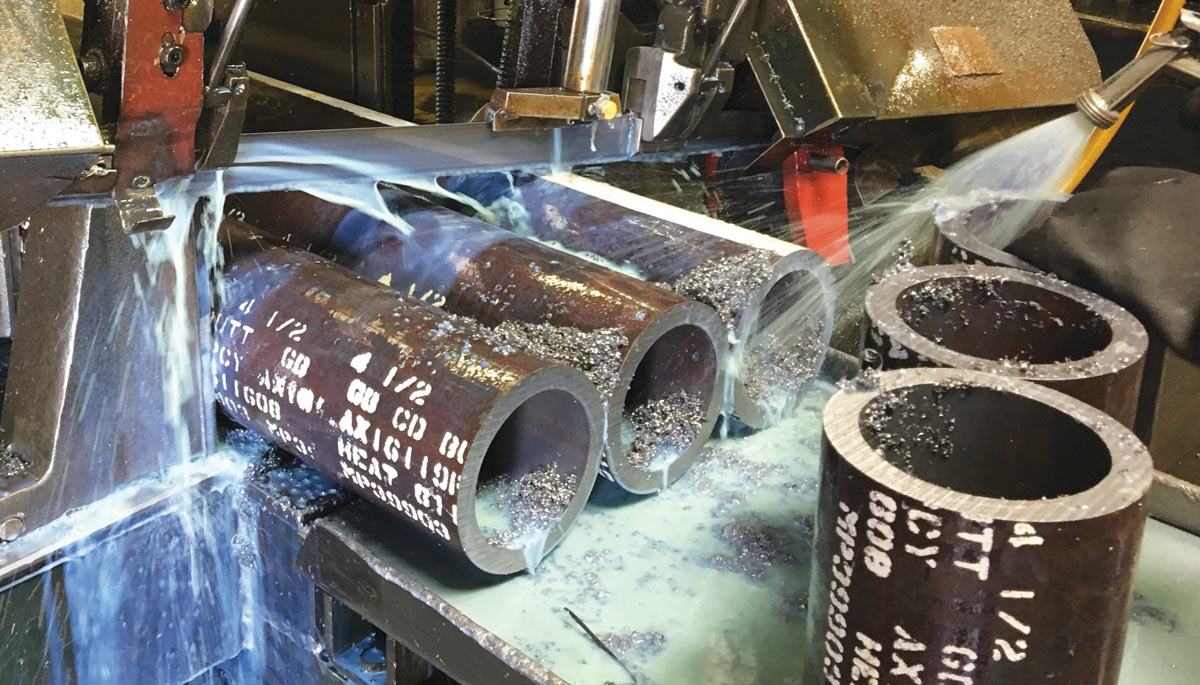

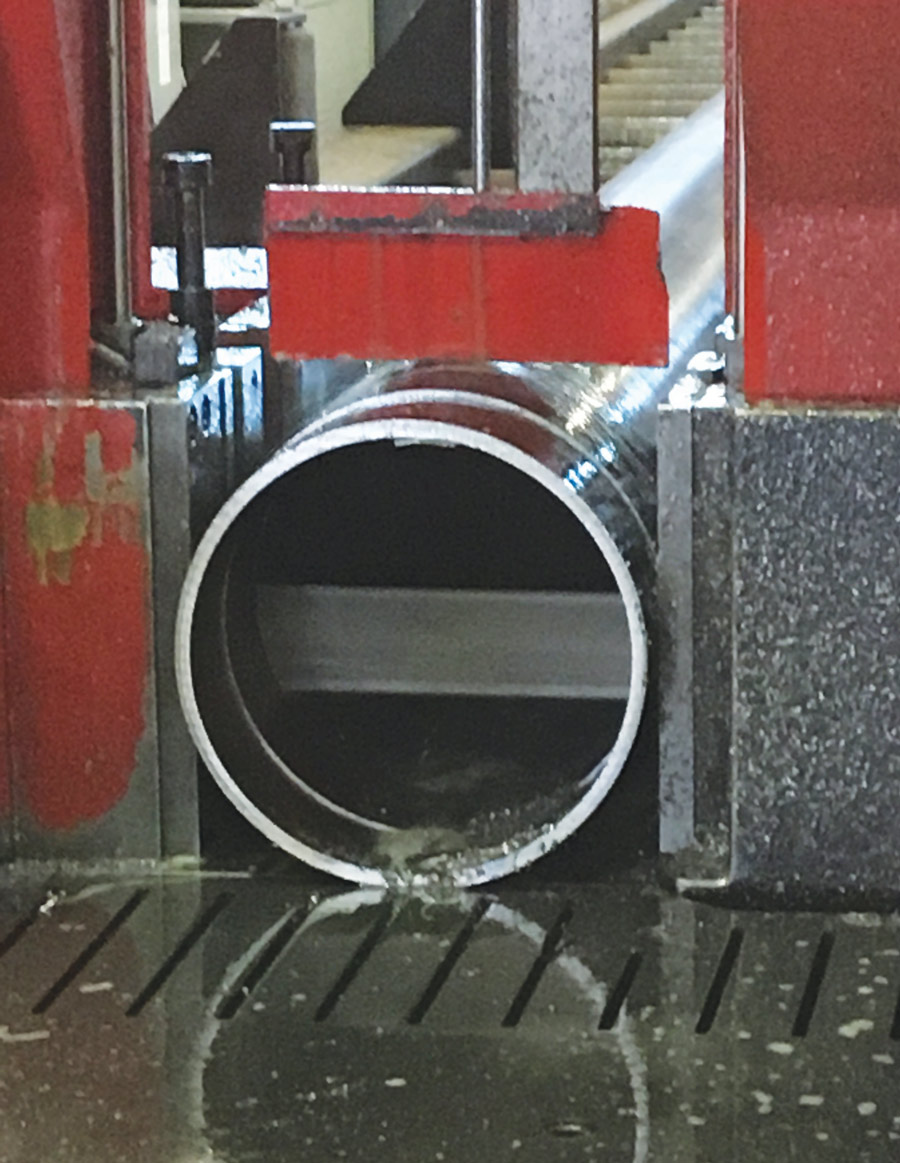

Although it is a universal band saw blade, the Proflex’s tooth design makes it optimal for sawing structural steel workpieces, which require overcoming the challenges of sawing with an interrupted cutting channel. For example, Masters says, when cutting a pipe, the saw blade initially moves into solid metal in which the blade is fully supported and the teeth are spread over a large section of the pipe. Soon, however, the blade passes through solid metal and starts cutting two walls separated by space. “Now you are supported by two small sections and it creates a lot of vibration,” Masters says.

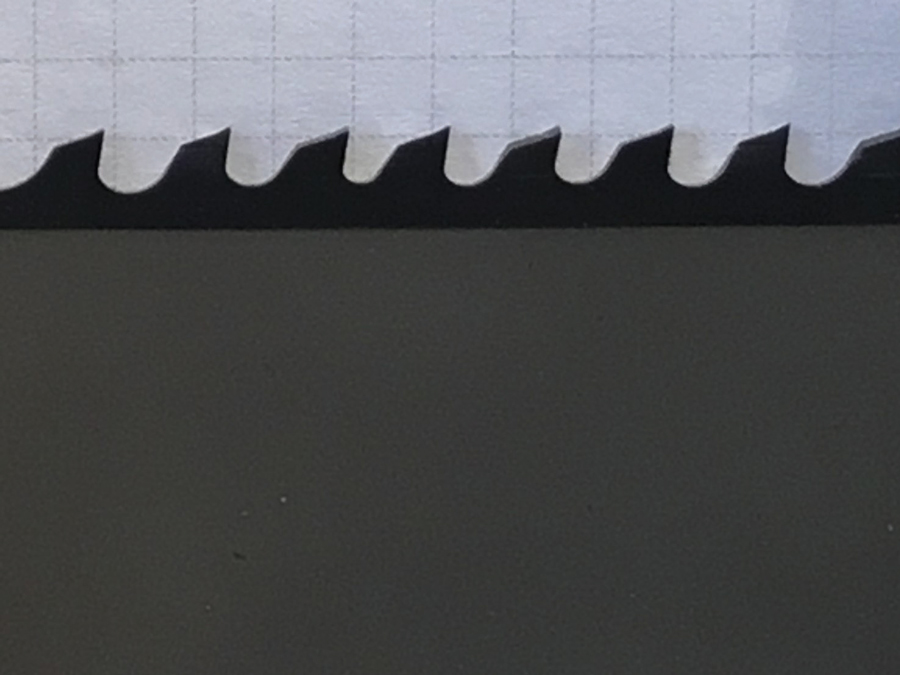

The Proflex blade’s tooth design features a duplex relief angle instead of a single relief angle. “If there is vibration and movement of materials to cause the teeth to chip, it’s designed so that the rest of the teeth don’t strip right off the blade.”

Some of the vibration created when sawing workpieces with an interrupted cutting channel can be reduced by having a machine with side clamping to squeeze both sides of a bundle and a top clamp that presses down, Masters says. Some sawing operators tack-weld the ends of parts together so they can’t spin during the cut or use steel strapping to tightly secure a bundle, but those methods add time and labor.

Heat and vibration are what kill that cutting tool.

Heat and vibration are what kill that cutting tool.

When the wall of a workpiece material is less than ¼-in. thick, Masters says a blade with a positive rake angle tends to shave and lift chips, snagging and pulling on the thin walls and distorting the workpiece. “That’s what is going to jam it into the blade and start stripping teeth.” For those applications, he recommends a blade with a 0-degree rake angle.

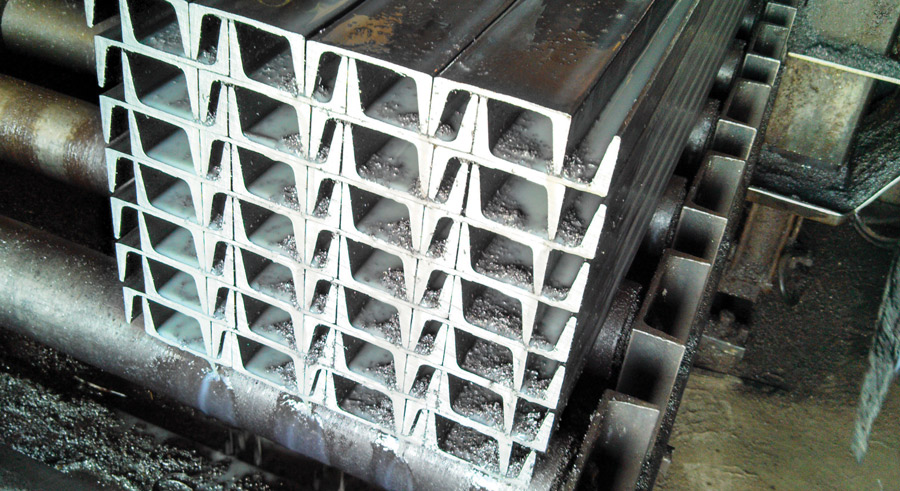

WIKUS also offers the Proflex SW M42 blade. SW stands for “set wide,” meaning the teeth are set a little wider than the other models to create a wider kerf and reduce the risk of the workpiece material pinching the blade and causing it to seize during the cut, Masters explains. “Whether it’s cutting tubes or channels or angles, you’ve got what people refer to as a pinching issue because there is residual stress in those plus the movement of the part.”

That problem is compounded when sawing large I-beams and the tables on the machine are not exactly level, he adds. “When you break through that web of material, that I-beam starts to pinch together because there is a lot of residual stress because of the way I-beams are processed.”

Masters says the Proflex blades are suitable for use on any type of band saw, and customers frequently saw parts that aren’t structural metals, but the majority of applications use flood coolant to lubricate and cool the blade/workpiece interface. “Heat and vibration are what kill that cutting tool.”

When all the sawing components are in order, Masters says the tooth design of the Proflex blade makes it well-suited for sawing structural workpieces. “It’s a real workhorse.”