Features

o say this has been an interesting year is an understatement. Since March, each of us has been impacted by the pandemic both at home and at work. In our industry, we all have had to learn to do things differently. Sales personnel have been unable to travel and talk with customers face to face. Instead, employees have had to connect through Zoom conferencing and learn to use platforms like YouTube to conduct equipment demonstrations. Trade shows have ground to a halt, including the metal fabricating industry’s premier events like IMTS and FabTech.

One of the things that remains a constant in a sea of changes is our dedication to finding unique solutions for the market. We are always looking for innovative ways to help companies tell their stories, whether it’s a technology advancement, a new product roll-out or the next step in a software product’s evolution.

usiness conditions at architecture firms stabilized in June, following significant declines in previous months, according to the American Institute of Architects. While June’s Architectural Billings Index score of 40.0 for the month means the majority of architecture firms saw billings decline month over month, the pace of that decline slowed.

Inquiries into new work nearly returned to the positive in June, as clients began trying to restart projects. However, the value of new design contracts lags behind, as many potential clients are price shopping to multiple firms but will ultimately select only one to work with. Firm backlogs began to tick back up, rising from an average of 5.0 months in March to 5.3 months in June. Concerns remain about whether the momentum will continue or if recent gains will be reversed by a resurgence of COVID-19 cases.

The Dodge Momentum Index, issued by Dodge Data & Analytics, fell 6.6 percent in June to 121.5 from the revised May reading of 130.1. The index measures the first report for nonresidential building projects in planning, which typically lead construction spending for such developments by a full year. The institutional component of the Momentum Index fell 11.7 percent while the commercial component declined by 3.5 percent.

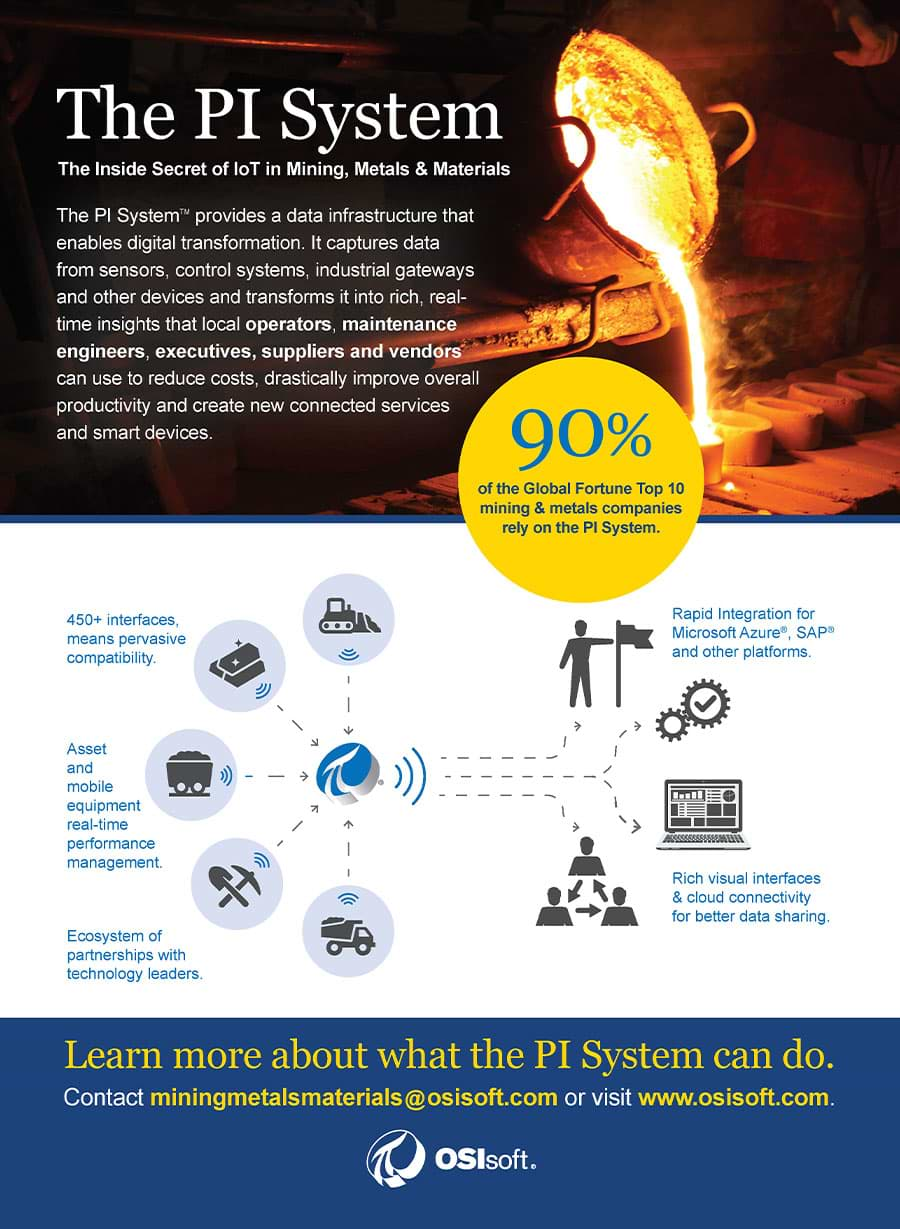

rices for both aluminum and steel have decreased steadily during the last 10 years—in the case of aluminum, dropping by nearly half since its 2011 high. Yet, energy and labor costs are on the rise. Energy costs alone can take up over half of a company’s operating budget. To adjust to these challenges, metals companies must either reduce their costs or produce more tonnage.

WIELAND ACQUIRES MARJAN AND NASCO

Industrial Magnetics Inc., Boyne City, Michigan, appointed Aaron Evans as regional manager for its Western U.S. territory, which includes Arizona, Utah, central and southern California, and southern Nevada.

Olympic Steel, Cleveland, promoted Andrew F. Wolfort to vice president of specialty metals. Wolfort will continue to lead the teams at Olympic Steel’s Schaumburg, Illinois, and Gary, Indiana, facilities as well as the Berlin Metals business. He’ll also support the Integrity Stainless business in Latrobe, Pennsylvania, and Streetsboro, Ohio.

Tim Fabian has joined Shape Technologies Group, Kent, Washington, as vice president of marketing and product management. Fabian has more than a decade’s experience in sales and customer service for metal processing machinery manufacturers.

FAB Supply Inc., Glendale Heights, Illinois, hired Ron Laws as vice president of sales and marketing. He has more than 30 years of experience in metal fabrication, including work with a large metalforming equipment builder.

Automatic Feed Co., Napoleon, Ohio, named Derek Faber as manager for the company’s automation integration manager (AIM) software suite. He supervises the AIM technical team and supports all AIM customer installations.

alifornia State Polytechnic University Pomona (Cal Poly Pomona), part of the sprawling state university system, sought for years to build a new Student Services Building but budget constraints dashed those hopes for a while.

In 2019, however, the dream was realized when the school opened a 140,000-square-foot facility that consolidates enrollment, registration, financial aid, cashiering and prospective student services into one-stop service centers adjacent to administrative functions.

alifornia State Polytechnic University Pomona (Cal Poly Pomona), part of the sprawling state university system, sought for years to build a new Student Services Building but budget constraints dashed those hopes for a while.

In 2019, however, the dream was realized when the school opened a 140,000-square-foot facility that consolidates enrollment, registration, financial aid, cashiering and prospective student services into one-stop service centers adjacent to administrative functions.

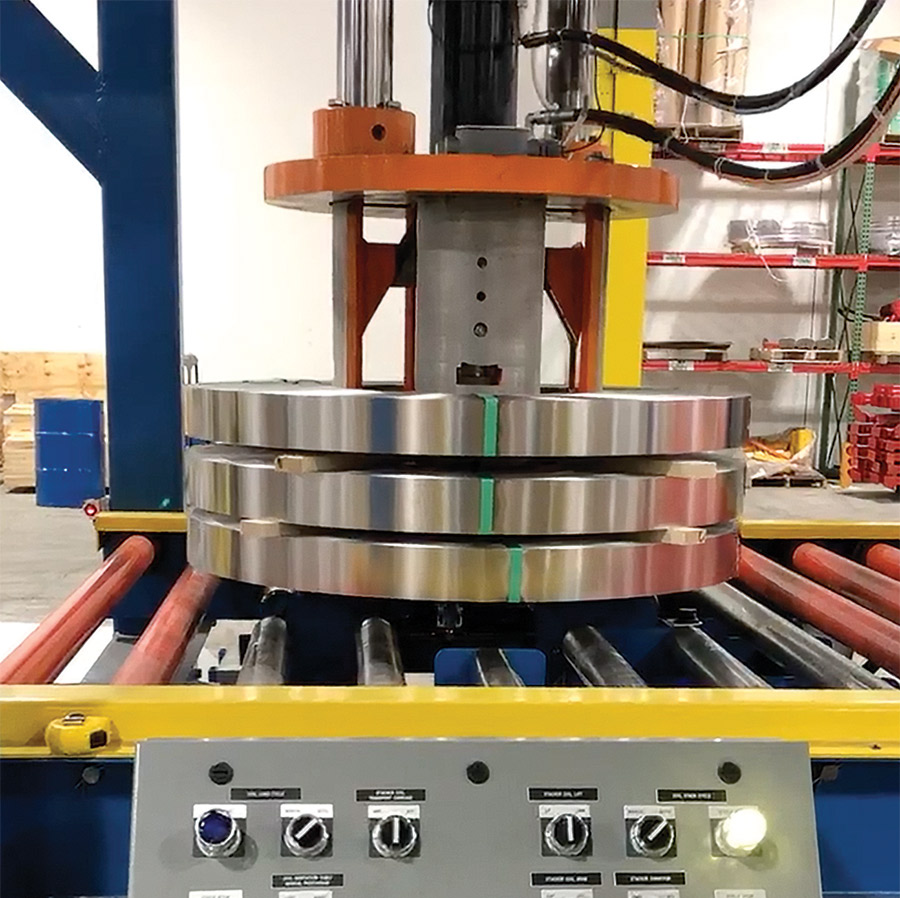

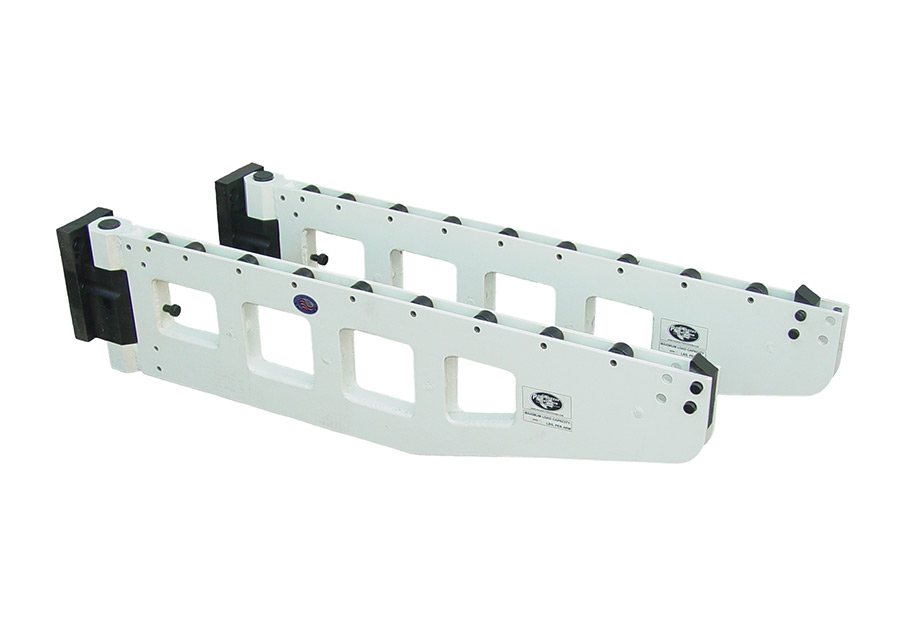

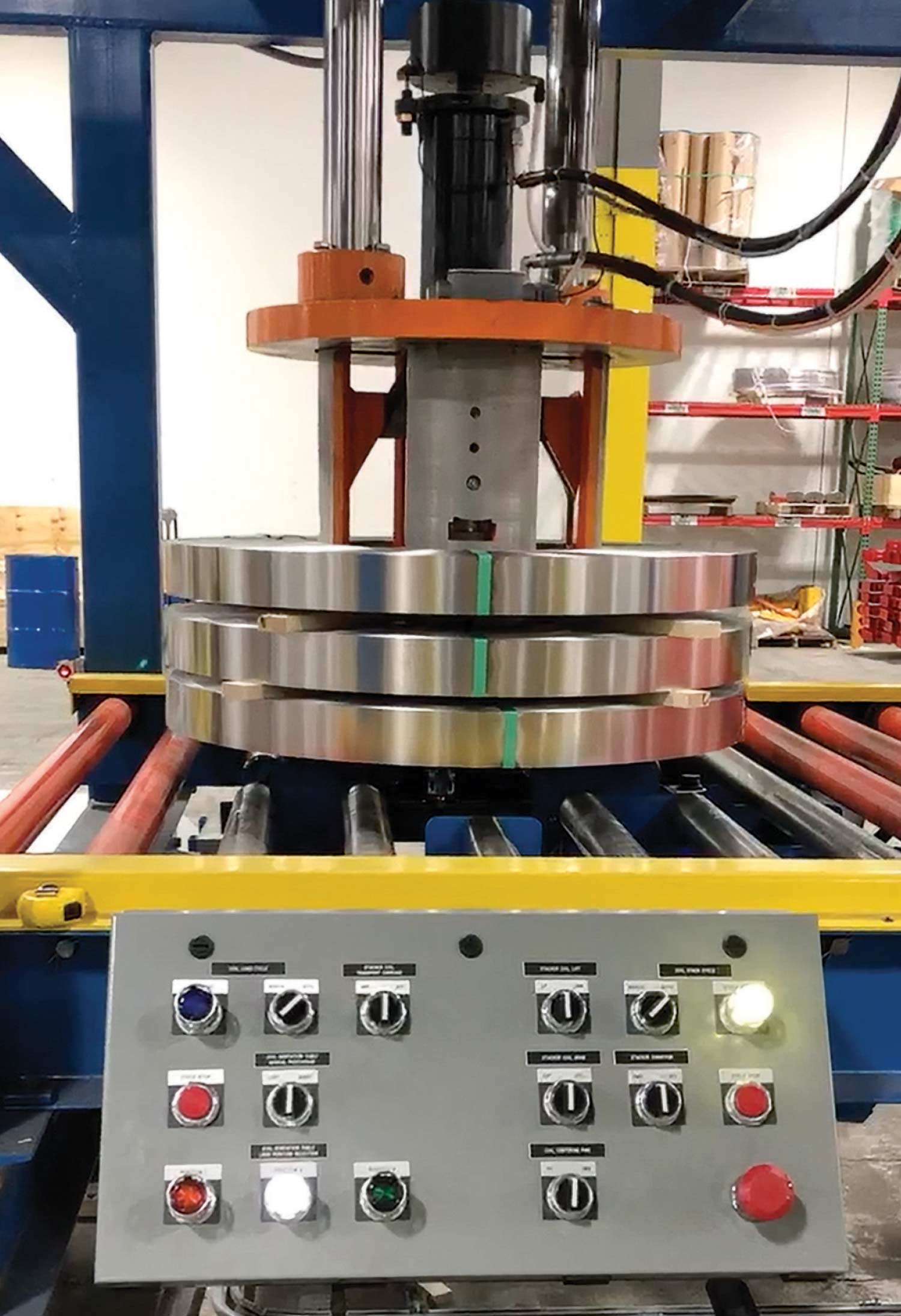

nyone who’s ever tried to cram an odd-shaped item into a box, or stuff a pile of unfolded clothing into a suitcase, knows that packing is easier when everything is organized and you use the right tools. When packing metal products to ship, there’s the added issue of safety, so not only does a structured operation create ease but it also reduces employees’ risk of injury, particularly when handling heavy materials.

Implementing an automatic coil stacker at the end of a processing line helps eliminate the ergonomic and safety concerns that crop up when handling coils manually, improves operator safety and creates highly organized stacks for packing.

here’s a metal fabrication shop in East Boston, located on the Inner Harbor waterfront and seconds from the runways of Boston Logan International Airport. Blue Atlantic Fabricators LLC’s specialty is assembling structures for heavy civil, bridge and marine contractors.

This requires the receipt, storage, in-house movement, processing and outbound shipment of large, long and heavy pieces of steel and aluminum, including large-diameter pipe, plate girders, piling and structural sections like rectangular tubing and I-beams.

option

option

here’s a metal fabrication shop in East Boston, located on the Inner Harbor waterfront and seconds from the runways of Boston Logan International Airport. Blue Atlantic Fabricators LLC’s specialty is assembling structures for heavy civil, bridge and marine contractors.

This requires the receipt, storage, in-house movement, processing and outbound shipment of large, long and heavy pieces of steel and aluminum, including large-diameter pipe, plate girders, piling and structural sections like rectangular tubing and I-beams.

any of the domestic steel industry’s roots are sunk into the soil of Gary, Indiana. The city was founded in 1906 by U.S. Steel Corp. as the home for its new Gary Works. It’s had ups and downs over the years, like many other Rust Belt towns, but it’s rebuilding for growth. Indiana as a whole is home to the world’s second-largest automotive industry and leads the nation in creating manufacturing jobs, among other accolades like second-ranked infrastructure in the nation and Chief Executive Magazine’s 2019 Top Five states for business.

Alliance Steel, a supplier and processor of flat-rolled steel, earlier this year completed a move of its headquarters to Gary and plans to become a integral part of the city’s future. The company purchased a facility in Gary that was originally owned by steelmaker Republic Steel and more recently by Gary Metal Products, a manufacturer of building vents and ducts.

We’re relentlessly committed to passionate customer service, offering versatile operations and the industries’ most expansive national footprint.

Come ride the VORTEQ wave of momentum for your coil coating needs! Let’s get started at vorteqcoil.com

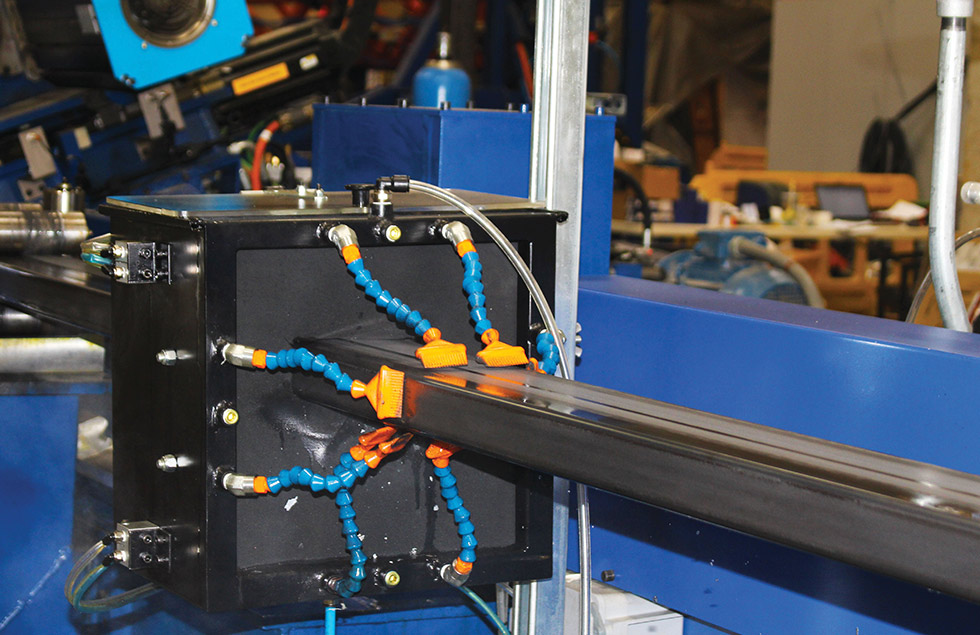

ith over 50 years’ experience in coil coating lines, The Bronx Group has seen many changes and developments within the metals processing industry. Typically, coil coating and processing lines have been large-volume lines, upwards of 100,000 tons per year. These lines required significant orders, long runs, large buildings and extensive working capital to run them successfully.

However, as Bronx Group continued to conduct its business globally, its leaders recognized that in servicing the market, there has been an emerging need for a more niche solution.

Market research found that small coils of varying colors, widths, lengths and thicknesses were in high demand. The coil coaters and those manufacturers who purchase coated coils required flexibility within their stock range while maintaining limited coil stock and pursuing just-in-time delivery. This can become difficult with the larger process lines, which prefer long runs of one color and cross section to run efficiently.

copper&brass

he months have seemed to drag for a lot of people, especially those who have been laid off or who saw serious slowdowns in sectors that are heavily dependent on the consumer economy. The manufacturing sector and the metals supply chain that supports it are essential, which means that although there have been hiccups, Farmers Copper is taking things day by day.

Modern Metals spoke with Co-Presidents Dicky and Bob Farmer, and a new addition to the staff, Macy Surovik, a marketing specialist, to find out how the company has adapted to the challenges of a global pandemic.

“We have been following the guidelines and staying safe and healthy down here,” says Dicky Farmer. “I never thought it would go on this long. I thought it would pass in a couple months. Now we see a spike [in cases]. But we have weathered a lot of storms,” including 2008’s Hurricane Ike.

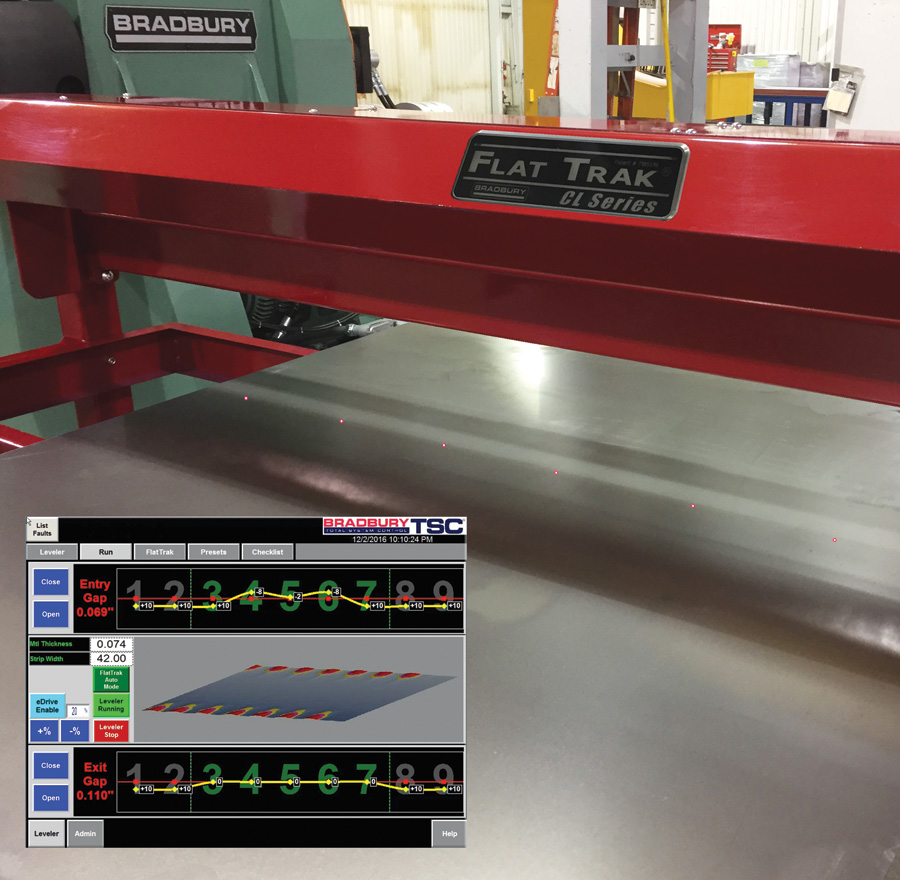

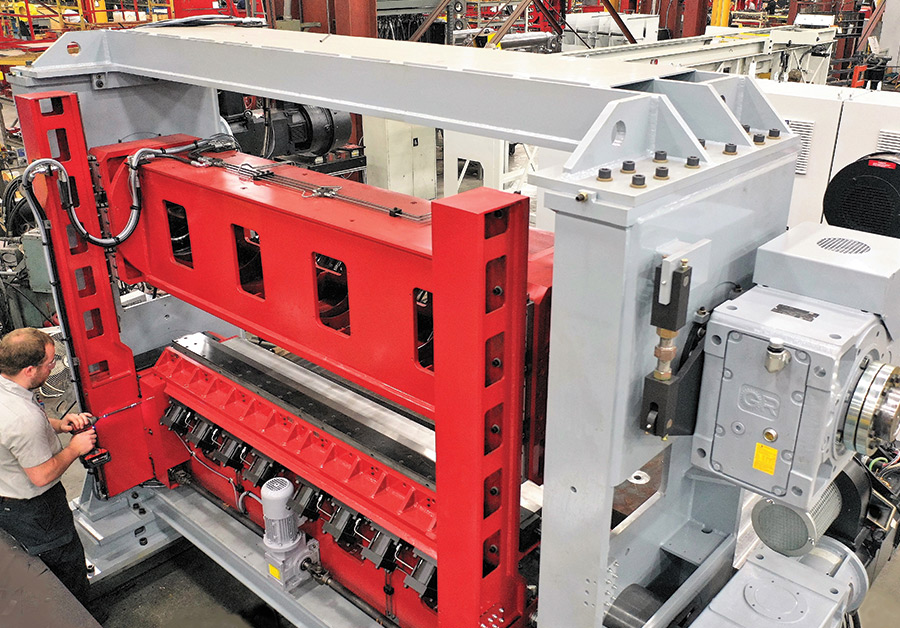

eveling is an experience-driven profession,” says Brownie Cox, leveler product manager for The Bradbury Co. Inc., Moundridge, Kansas. “As the strip moves through the line, it is ever changing, and the operator must react to these changes, making knowledgeable adjustments to counter the wave problems.”

Without an experienced operator at the helm, levelers can create a lot of expensive scrap. “New people require experience to get things set up right,” Cox says. “Scrap is the result of adjustment errors and inexperience. The second issue is inattentiveness. It is difficult to watch the strip all the time.”

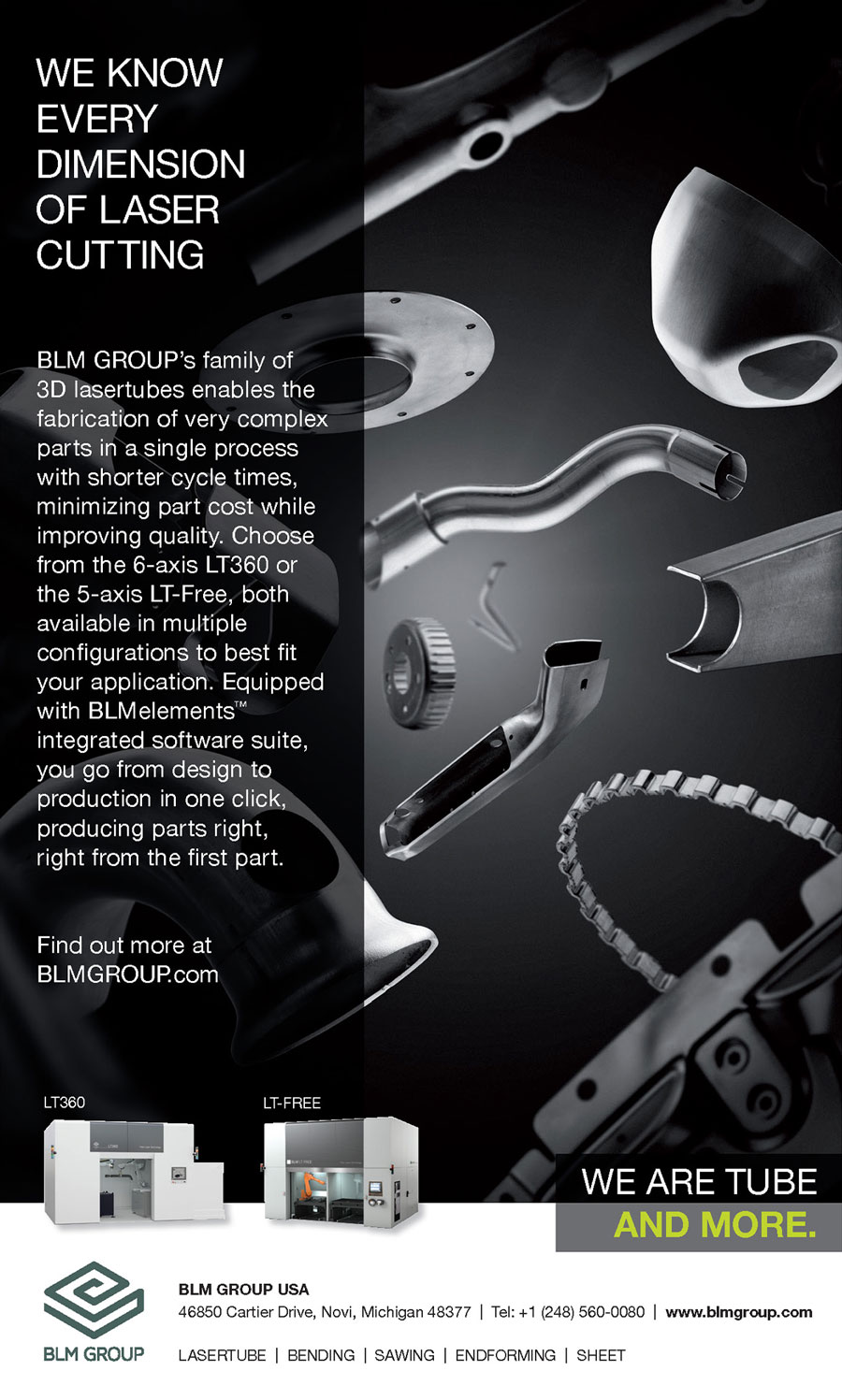

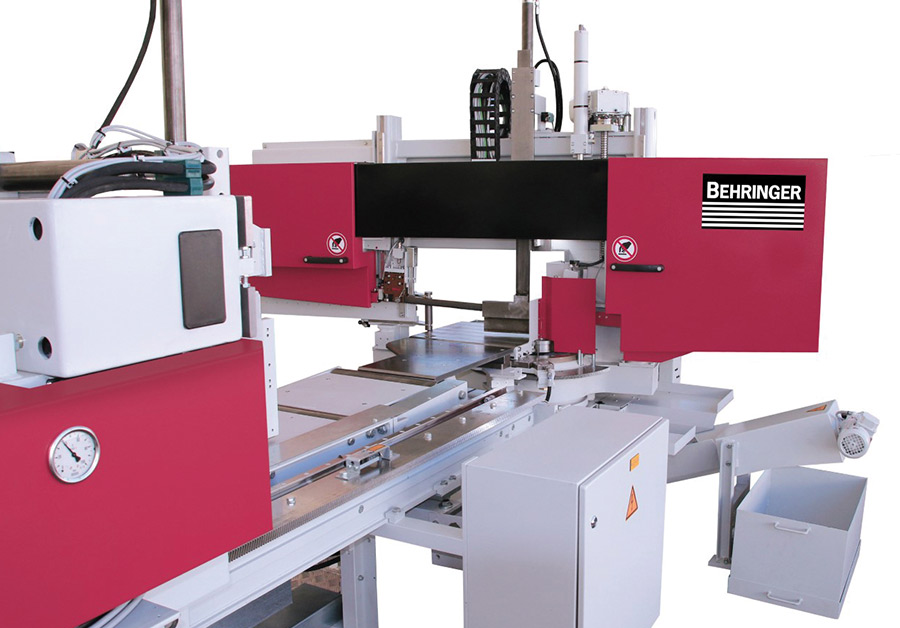

sawing/cutting

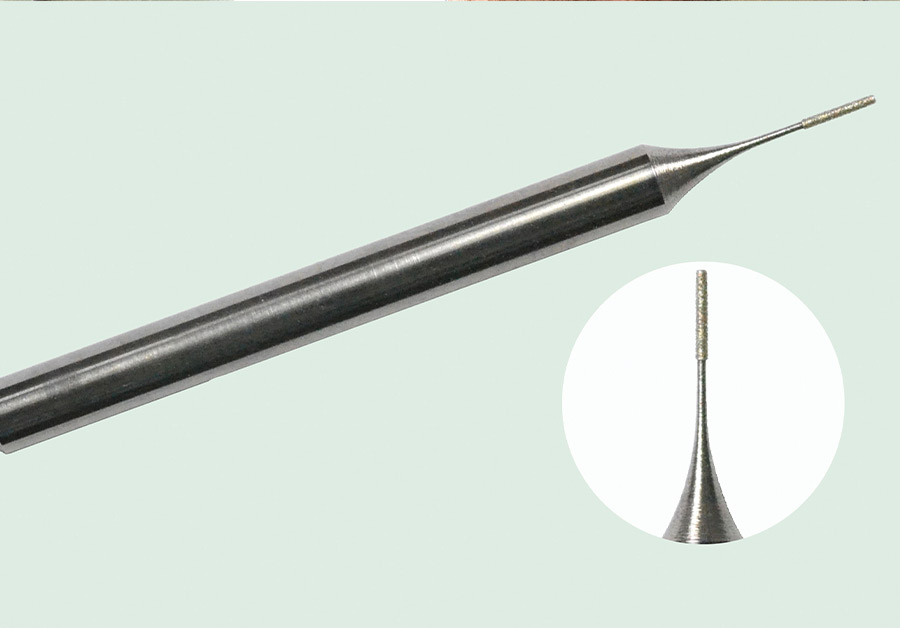

uperalloys are being selected more frequently to replace carbon steel alloys in a variety of applications. Superalloys are specifically designed to have high strength at high temperatures, making them ideal for the aviation and aeronautic industries and other environments where these special properties are required. Superalloys are also more resistant to corrosion, oxidation, and wear and tear.

Composites are a combination of elements in a structure or atomic arrangement, which is often complicated and repeated regularly in the configuration of their structure. Superalloys use the power of “phase variation.” This means that instead of having one atomic arrangement repeated throughout the material, superalloys have multiple atomic arrangements known as “phases.” A simple comparison is water versus ice. Ice has the same molecular composition as water but a different atomic arrangement or phase. The physical properties of the material are much different, even though the molecular composition is the same.

Advertiser Index

View Index

partingshot

Fitness Center

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.modernmetals.com

312/654-2309, Fax: 312/654-2323

mdalexander@modernmetals.com

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@modernmetals.com

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Oklahoma, Pennsylvania, South Carolina, South Dakota, Tennessee, Texas

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@modernmetals.com

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@modernmetals.com

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@modernmetals.com

Modern Metals® (ISSN 0026-8127, USPS 357-640) September 2020, Vol. 76, No. 8 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Modern Metals® (ISSN 0026-8127, USPS 357-640) September 2020, Vol. 76, No. 8 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.