here is a lot of potential for digital solutions in the metals industry, according to a recent survey by McKinsey and Co., which collected perspectives from 30 leading metals companies around the world. The results showed that there are five main success factors to scaling digital and analytics: setting bold targets and strategies, investing, setting up a flexible data and technical architecture, building skill sets, and implementing the right governance behind data and analytics programs. “Companies that successfully harness the potential of digital will be the first to capture breakthrough increases in top-line revenues, capture the next 10 to 15 percent of cost improvement and leapfrog ahead of the rest of the industry,” the consultancy’s analysts said.

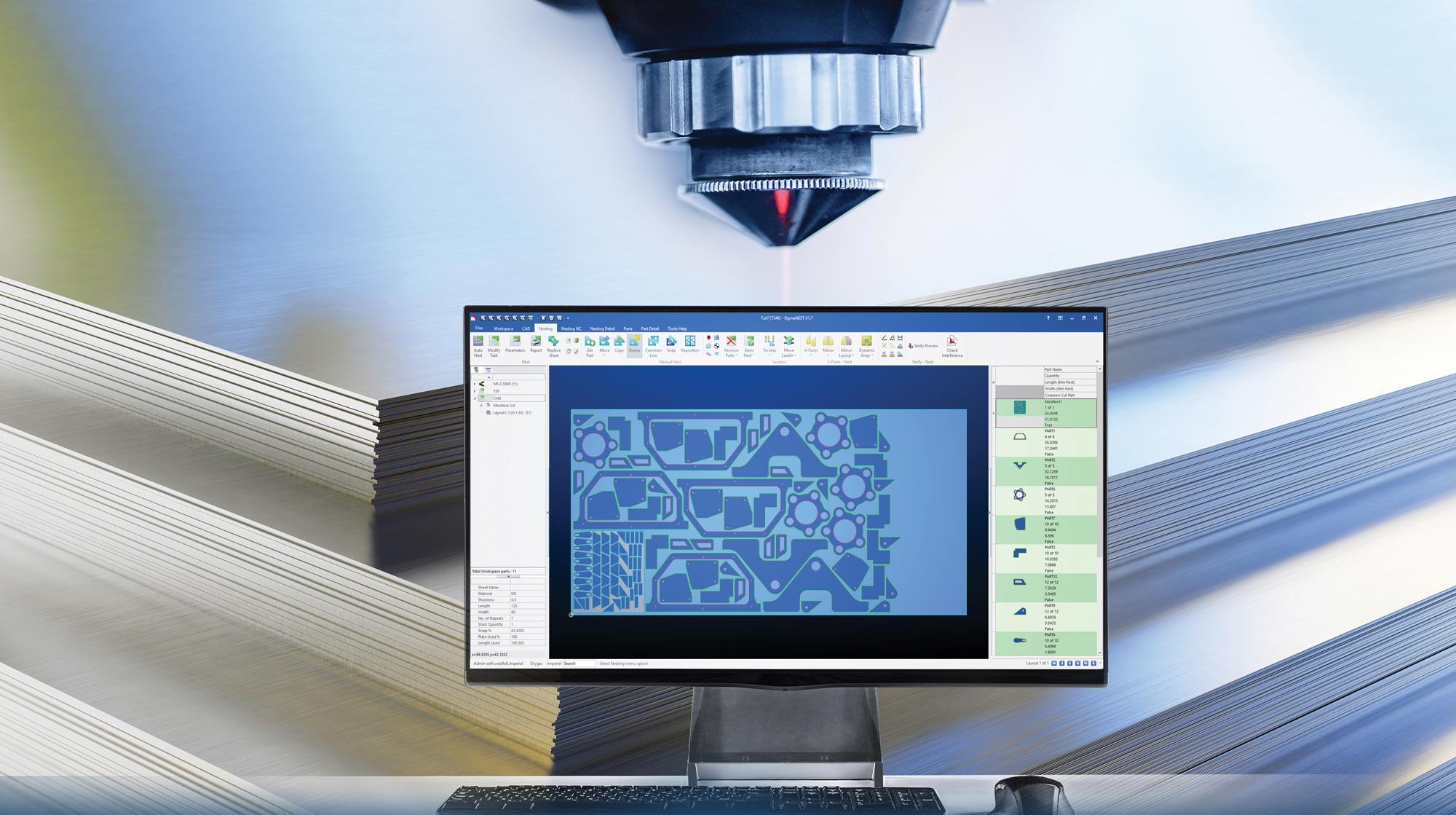

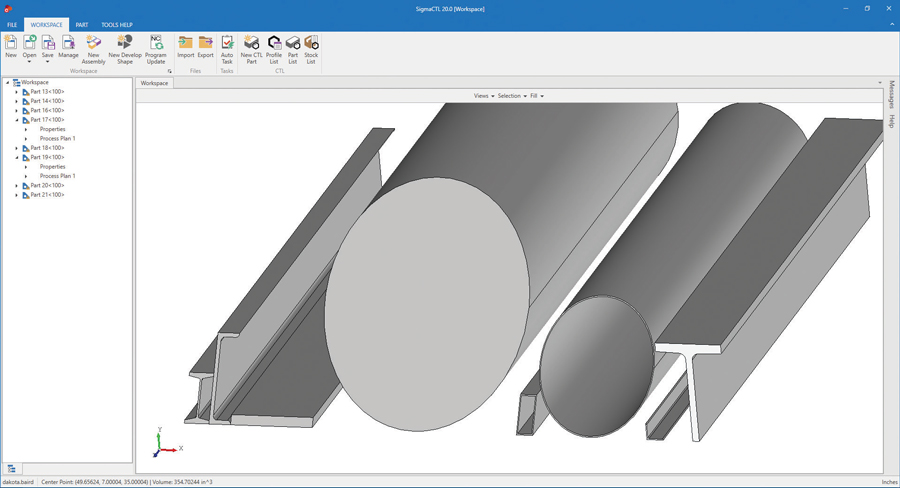

SigmaNEST can import parts from any major CAD system, automatically sort them into tasks by material and machine, optimize material usage and machine motion, post programs to profile cutting machines, and track productivity from start to finish.

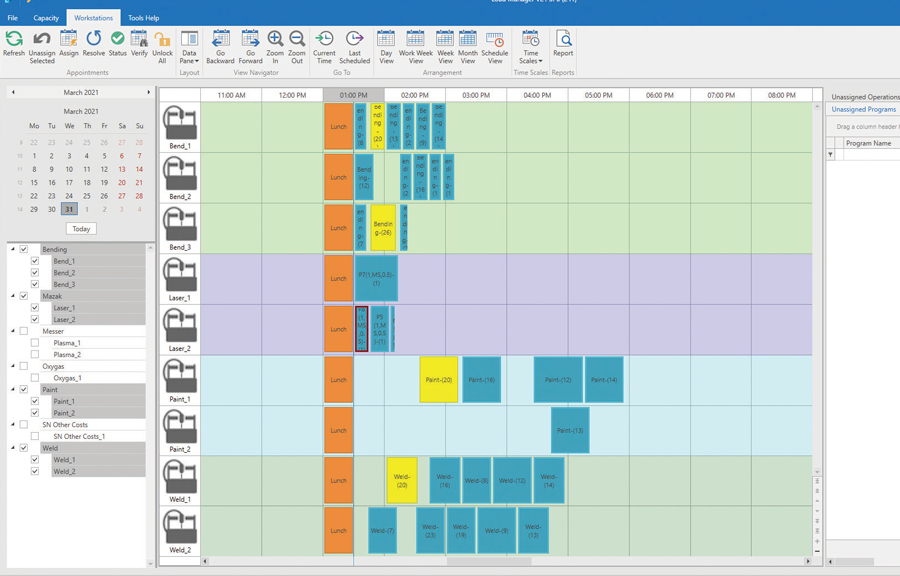

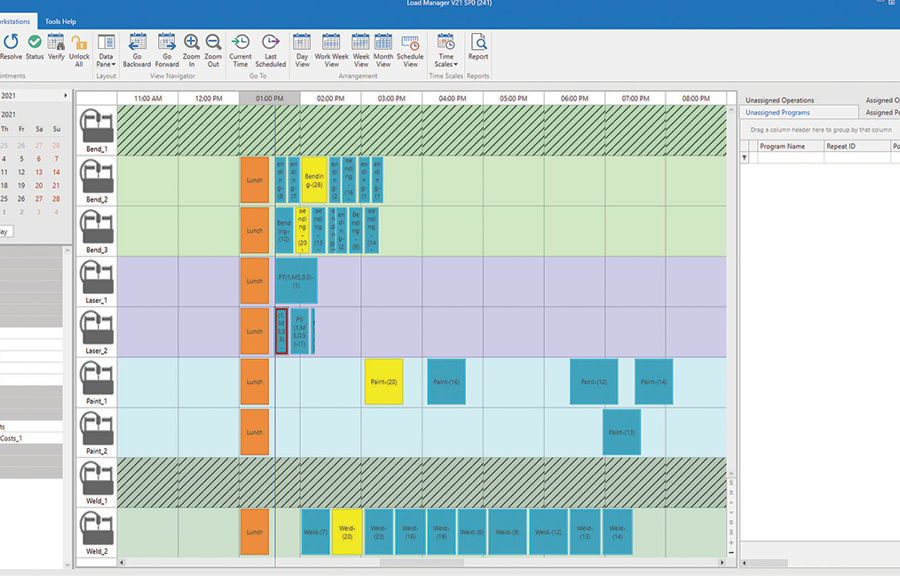

These smart functions mean that customers no longer have to manually keep track of parts, and it makes it easier to shuffle jobs based on priority. “If you have a bunch of nests set up and then get a hot order, you have to find the nests that contain the hot part so they can be cut first,” says Cathers. “I’ve seen companies go into a conference room, take all the pieces of paper with the programs they need to cut for the day, lay them on the conference table and pick out the hot parts. With scheduling software informed by CAD/CAM integration, we push a button and readjust the schedule.”

SigmaNEST software helps control many different shop functions, including inventory purchasing, programing cutting machines, and moving material. “We work from the start with the customer to fully understand their business, how they operate and how they manage their data,” says Baird. “We do that discovery process up front so we can ensure customers receive the software that can bring them the most benefit.”

With a fully integrated system, you don’t have to go looking for information.

With a fully integrated system, you don’t have to go looking for information.

“With a fully integrated system, you don’t have to go looking for the information. It’s always just right in front of you,” says Cathers. He points out that after implementing this type of system, companies can’t even fathom returning to their previous methods since previously cumbersome tasks are now done with the click of a button. “Customers can’t imagine going back to doing everything on paper or having an army of people to manage and schedule and complete all these tasks that the software just does automatically.”