Transportation & Logistics

i’ve been here almost 15 years. I stay because i love sunline and wouldn’t want to be anywhere else

i’ve been here almost 15 years. I stay because i love sunline and wouldn’t want to be anywhere else

manuel soriano, sunline driver

t’s a story most readers have heard before—the one where a few overworked, overtired “kids” didn’t know any better but still figured out how to make a go of a startup company. That is the story of Sunline, a San Antonio, Texas, asset-based carrier that started out as a family enterprise in 1994 with four owners and it still retains all the original kids.

Over time, this family worked to cultivate long-term relationships with vendors, employees and customers based on intelligent solutions so that all stakeholders could grow successfully together. Today, the company employs about 70 people, including drivers.

Sunline operates both domestically and internationally. With its roots in South Texas, the core business began with international shipments from the region but quickly grew to serve several other border regions from Texas to California and, ultimately, Canada. From those beginnings and relationships, domestic coverage has also increased year over year, including a strong presence across the Midwest.

Sunline recognized an opportunity to change its culture, which has kept the company ahead of its competitors. Procedures include developing efficiencies such as loading schedules at low peak hours and proactive and measurable communication for critical shipments. The culture, meanwhile, ensures that everyone at Sunline shares ownership in the final result, which is being the dependable choice for clients, employees and drivers.

Internally re-educating staff and operators on the importance of meeting on-time pickup and delivery is just part of the continued education at Sunline. Other procedure-based training includes cargo securement, timely communications and molding services for each client, rather than the client having to settle for a boxed form or service.

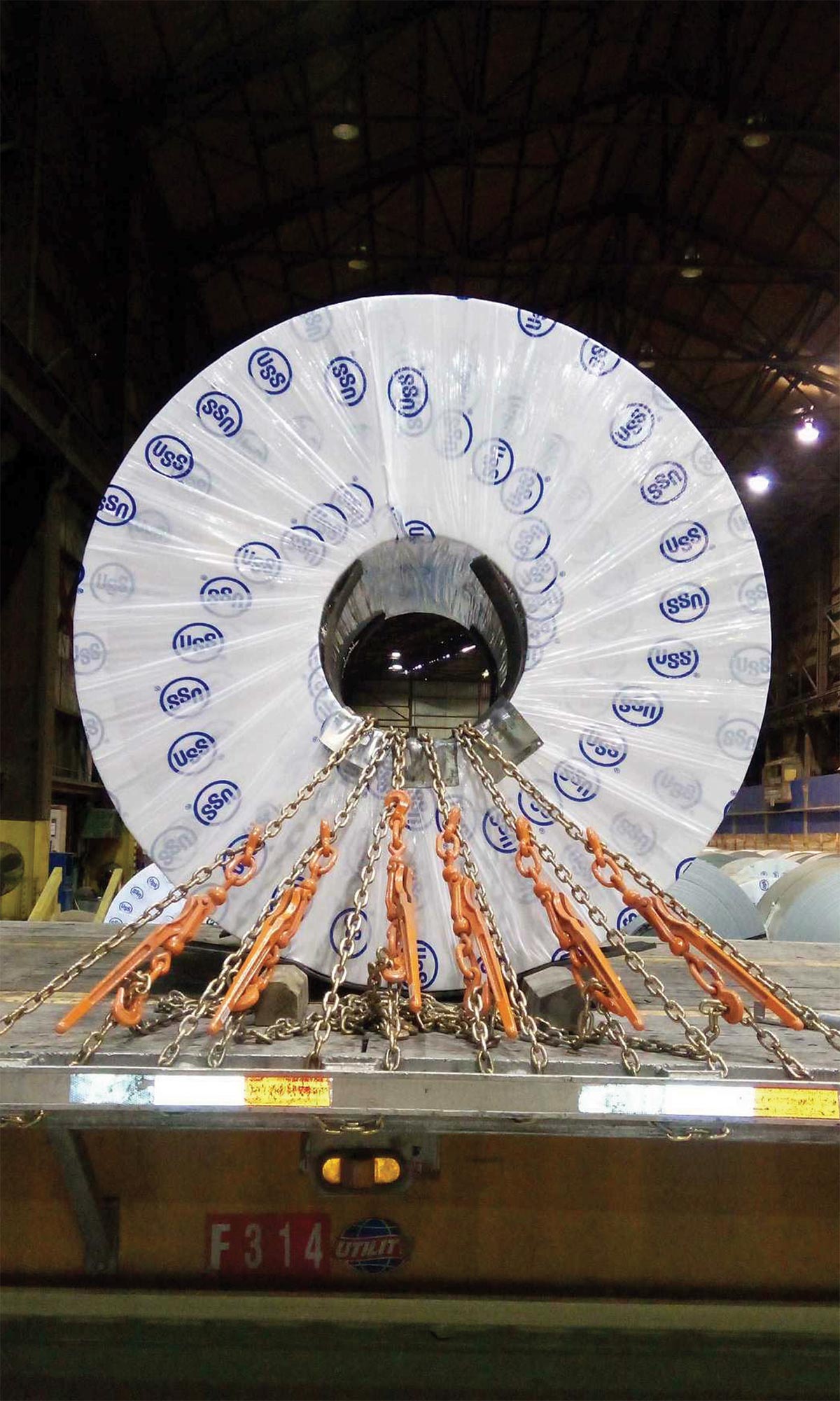

Adding transparency, many of Sunline’s procedures were developed after in-person visits at client locations and creating the teamwork ethic so that everyone is clear on how each commodity is supposed to be handled, secured and delivered to the final consignee. This has been key for Sunline in achieving the expected results to the end users, drivers and operational staff.

At first, the company attempted short-term fixes to the expanding issues but soon realized the new norm and started looking at more permanent plans, including:

- Scheduling drivers around peak loading/delivery times.

- Assigning Sunline personnel for on-site loading procedures and training.

- Detailed reporting for on-time and transit time performance.

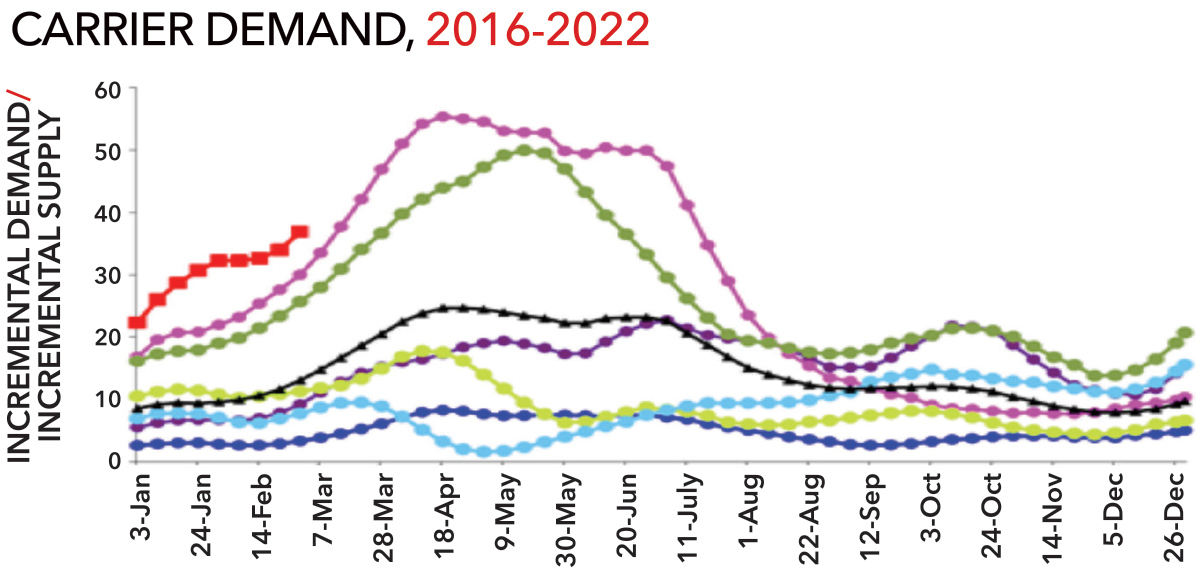

- Sharing market trends that clients might not have access to.

- Dedicating groups of drivers for certain lanes to avoid learning curves.

- Single point of contact for each client, cutting down on communication variances.

With a long track record of being a relationship-based company, Sunline has the capacity to serve additional metals industry clients both domestically and internationally and offers a fresh and nuanced outlook on supply chain solutions.