he pandemic laid bare some of the negative aspects of globalized supply chains. Although there is no real likelihood that purely localized economies will return, there has been substantial consideration for reshoring work that has been done overseas for years. This is a positive development, but one critical aspect that goes into the decision of how and where a product is produced is simple consideration of profit margin. Wealthier nations have labor forces that are considerably more expensive than those in the developing world. Setting aside the current disruption, for domestic production to make sense it must be efficient—and it must be intelligent.

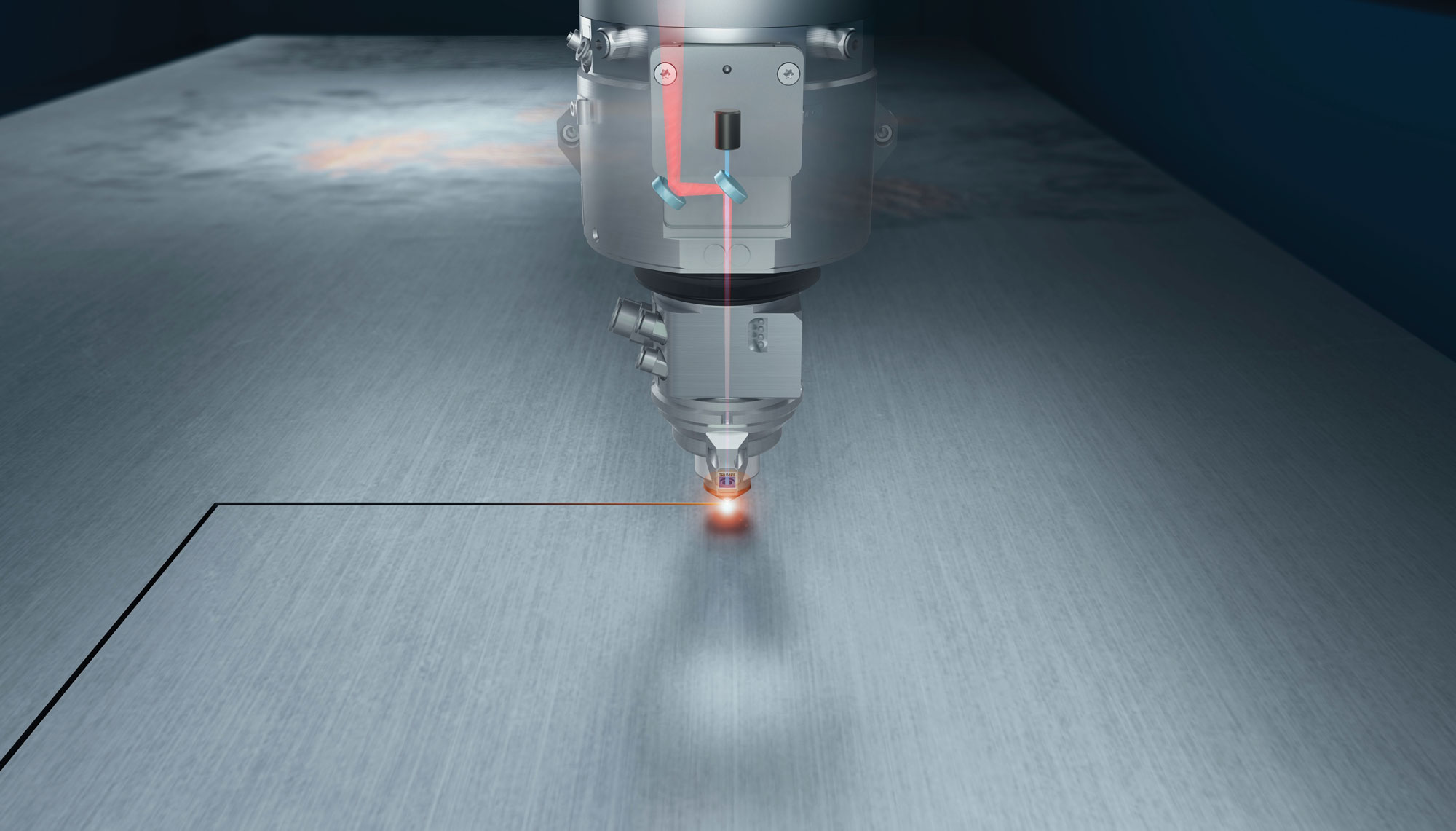

When considering how to make manufacturing operations smarter and more efficient, one must first look at technology designed to address the cutting process itself. Numerous factors can affect the quality, reliability and the speed at which parts can be cut. The consistency and quality of a material’s surface condition should be taken into account. And various alloys and deviations in thickness can influence cutting processes.

Other factors include heat transfer into the material and surface coatings (e.g., vinyl or oil) and the condition of the laser cutting machine itself. Basic questions to ask are: Is the operator keeping the protective glass clean? How is the beam alignment, focus and nozzle condition?

Numerous factors can affect the quality, reliability and the speed at which parts can be cut.

Numerous factors can affect the quality, reliability and the speed at which parts can be cut.

These additional factors can determine whether production will be successful, or whether it will be frustrating and costly. Active Speed Control from machinery builder TRUMPF Inc. ensures that quality and performance meet the users’ expectations. It’s a completely automated solution that proactively addresses cutting process conditions. Prior to this type of automation, any change in conditions required operator invention; a person would have to first notice that a problem was occurring and then react. Even in a best-case scenario where the operator does promptly intervene, it can never be done as quickly as Active Speed Control, which is a virtually instantaneous response to ensure the laser keeps cutting.

Active Speed Control also can speed the laser up over its baseline feed rate. When, for example, TRUMPF’s TruTops Boost software provides an estimate, that number is based on the feed rate from the cut speed chart. When Active Speed Control is enabled, the times are typically based on a feed rate that is approximately 8 percent slower than what the machine will run at. At a high level, the process reliability and the reliability of the OEE estimate are key to ensuring profitability, particularly when margins are tight.

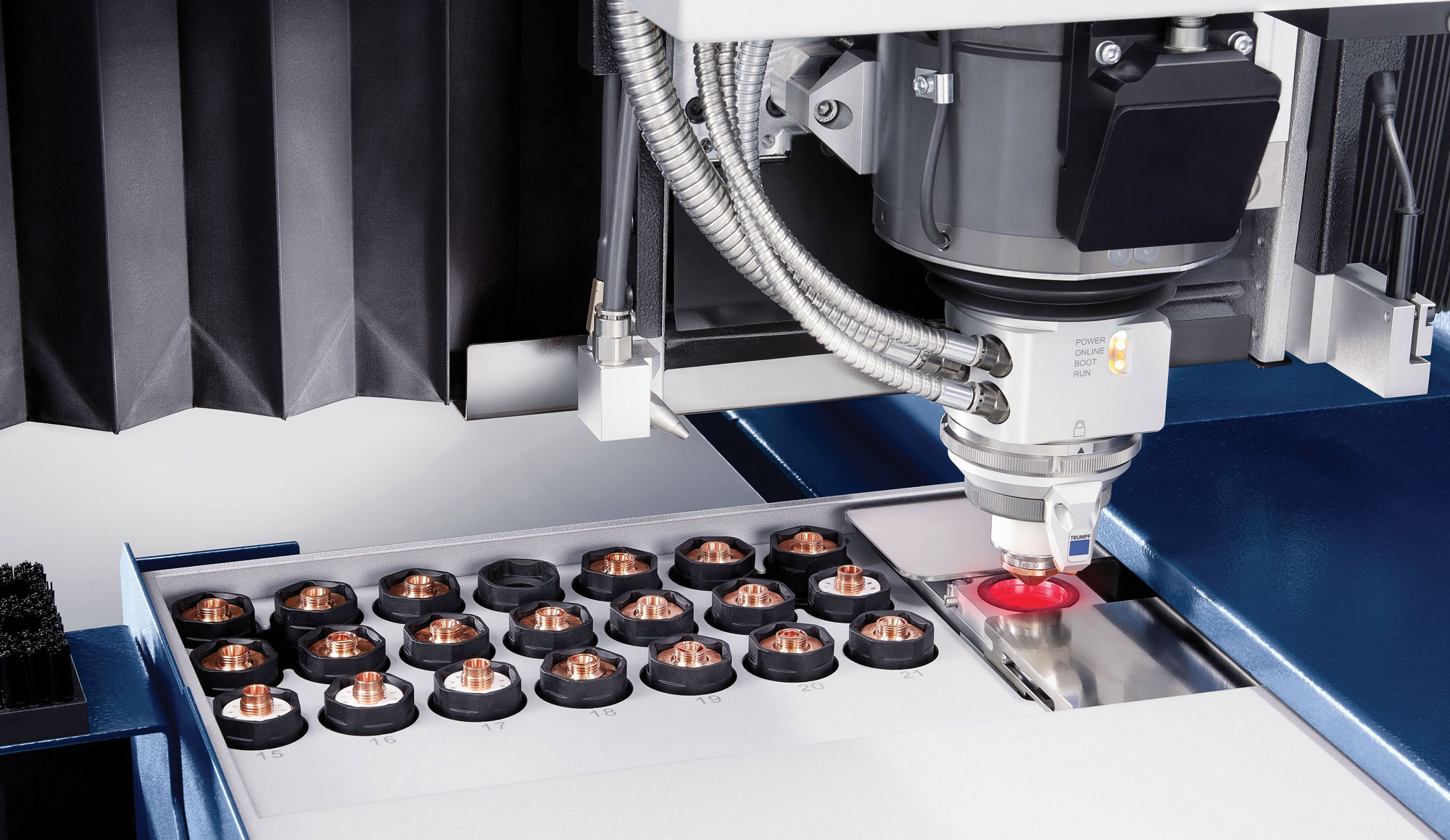

What if an issue arises that has less to do with the material and more with the hardware? Unattended production will often necessitate tabbing of the parts in the nest. The reason for this is if you have a tip-up, then you might have a collision, which causes damage to the nozzle. A damaged nozzle means poor cutting quality.

The Active Speed Control system will ensure that a damaged nozzle won’t cause production to go bad, but it still requires a way to inspect the nozzle without a person in the immediate vicinity to intervene.

This is where Smart Nozzle Automation enters the picture. If a collision occurs, then Smart Nozzle Automation will initiate a scan of the nozzle. After the scan is finished, a 3D representation of the nozzle is inspected by the software. This step will determine whether the nozzle has limited or no damage and can continue to operate, or if it needs to be swapped out for a new nozzle. If Smart Nozzle Automation does determine that the nozzle is damaged, it then places the nozzle in a numbered location and locks it out of rotation. Due to the parallel-to-production nature of the nozzle changer, the operator can even access the nozzle station while the machine continues to produce.

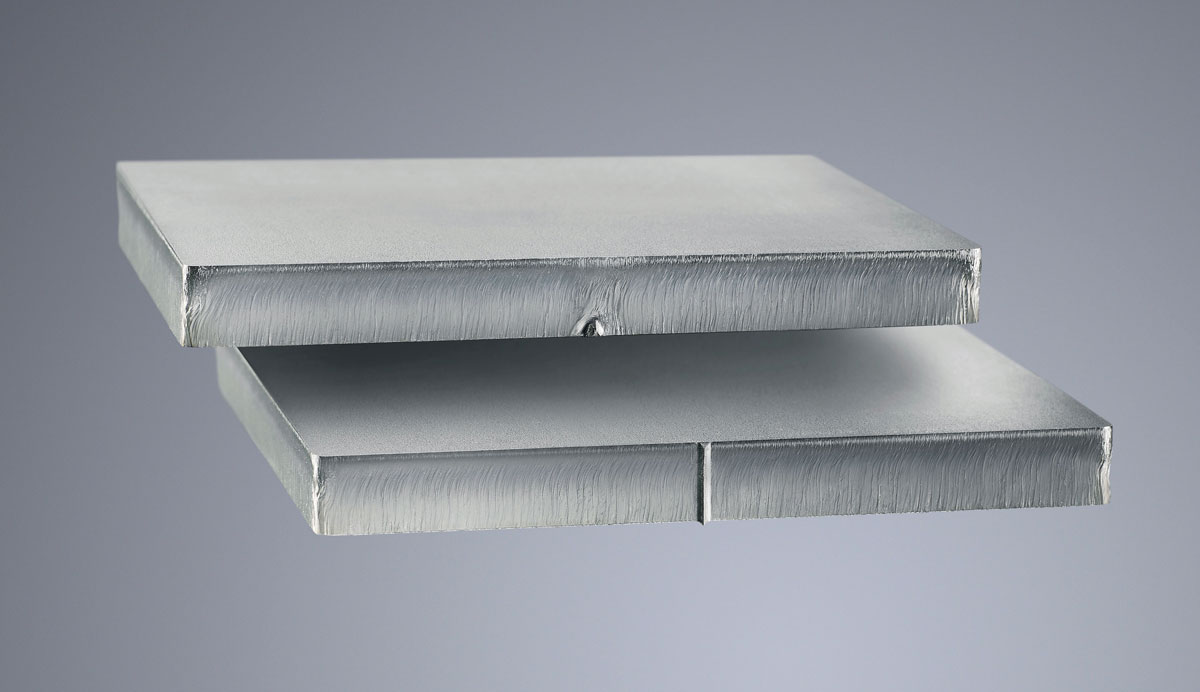

Tabbing parts into a nest is the best way to avoid interruptions to production, such as cutting unit collisions or parts jammed between pallets. Obviously it’s best to avoid these problems, but part tabbing is a classic Catch-22. Neglecting to implement tabs increases the likelihood that something will happen that requires secondary processing. (Tabbing parts always requires some secondary processing.) The real magic trick is to find the best combination of enough tabbing to make production reliable without adding a huge chunk of time on the back end to break parts out of the nest and grind off the tabs. This is where nanojoints come into play.

A nanojoint is made possible by the TruDisk’s beam management system and the onboard TruControl. With this interface to myriad functions and systems on the laser (not just on/off switching), the TruDisk laser can ramp its power level quicker than the blink of an eye to leave behind a tab. But, instead of being the typical through-thickness of the material, this tab is just the smallest remnant left only on the bottom side of the cut. It is so small that an application of powder coat covers it completely, eliminating the need to grind anything away.

Additionally, a nanojoint has the added benefit of being self-supportive. When a tab is left only at the bottom of the cut, the result is that the tabbed parts fall “together” at the top, keeping them from being separated by their own weight. When picking up the part and moving the edges away, the tab easily breaks, leaving little behind to show the part was even tabbed at all.

Because the nanojoint is created on the fly, an operator can place as many as needed. And, a nanojoint has zero impact on run time, regardless of how many are added into the nest, unlike traditional tabs where more than one tab needs extra time to cut, stop, position, pierce and then resume cutting.

Despite all the pain metalworking companies have collectively experienced during the pandemic, maybe something good can come from it. If more production becomes local, shortening the supply chain, it will help avoid shortages and inflation. The situation can also prompt companies to offer good jobs to more people who can take pride in manufacturing. The only way to compete in a global marketplace is with innovation and efficiency.