abricating high-end residential and public art requires a machine tool that’s versatile enough to cut a variety of materials and programming software that is user friendly. Scott Gallagher, a partner at Metalistics, says he found what the Everett, Washington-based manufacturer needed in the Mach 500 abrasive waterjet cutting machine and the FlowXpert software for 3D modeling and programming from Flow Waterjet. In addition to waterjet cutting, Metalistics provides rolling, forming, fabrication, installation and design services. The company’s other partner is Scott’s brother, Chris, and eight employees work 10-hour shifts four days a week at Metalistics’ 10,000-square-foot facility. The two brothers founded the company 20 years ago.

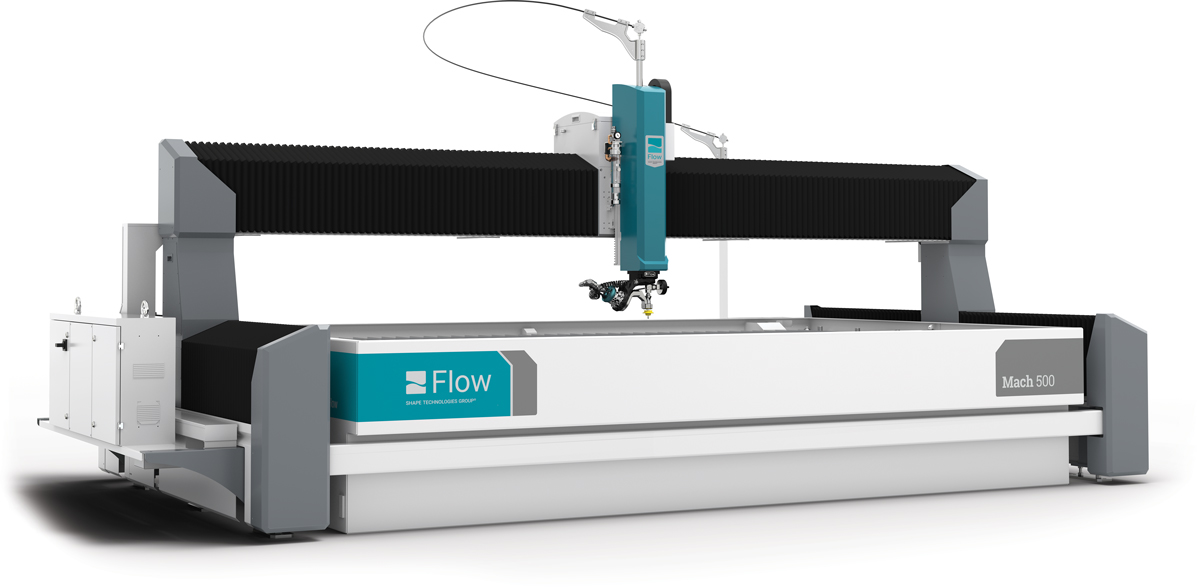

Purchased in spring 2021, the Mach 500 with the Dynamic Waterjet XD cutting head replaced the company’s previous Flow waterjet machine, which worked well but did not have taper control, Gallagher says. The latest model features taper control, as well as 5-axis capabilities. “We were constantly shimming the head to get straight cuts out of [the older machine].”

The 5-axis head proves advantageous, for instance, when cutting intricate stair stanchions for a table rail and when holes need to be pierced at an angle that matches the stairs and enables a cable to run correctly through a pipe, he says. “It’s quite a machine.”

The Mach 500 has the HyperJet 94,000-psi intensifier pump from Flow. The previous machine’s pump was rated at 60,000 psi, Gallagher explains, but the fabricator runs the ultrahigh-pressure pump at about 80,000 psi to extend its life between rebuilds. “We’re still cutting faster than we were with the old one.”

When shopping for the new waterjet, Gallagher says he didn’t want to limit his options or accidentally overlook a new technology, so he conducted research. All that research brought him back to Flow. For example, he found people are typically happier with Flow waterjets versus other brands. “That kind of steered us back to what we already knew.”

We use the waterjet for just about everything now. It’s quite a machine.

We use the waterjet for just about everything now. It’s quite a machine.

The company also serves laser cutting shops that are unable or too busy to perform all of the incoming orders in house, he adds. “We do a lot of outside work.”

For its own fabrication projects, Gallagher says Metalistics is gravitating more toward waterjet cutting and rarely shears parts anymore.

“We use the waterjet for just about everything now. The guys have gotten so lazy that nobody likes to drill holes or anything anymore and lay them out,” he quips. “They can draw it right on the screen and cut the plate with the holes in it.”

Gallagher adds that Metalistics tries to keep as much work as it can in house. “I rarely buy anything cut to size anymore from the metal suppliers unless it is something I can’t do.”

Gallagher says he also appreciates that waterjet cutting doesn’t create a heat-affected zone on workpieces, which prevents discoloration, and because most architectural metal components must be aesthetically attractive.

Although the FlowXpert software for 3D modeling and programming was new to the fabricator, Gallagher says the software is intuitive and enables Metalistics to directly import from the 3D CAM programs it uses. “It’s a really awesome program for modeling and programming the machine for the 3D cuts.”

The package also covers replacement parts, but very little service work has been needed, he says. “We had a couple of parts go bad, but we’ve been doing this for so long that we just install them [ourselves].”

Gallagher says Metalistics runs its waterjet programs through simulation software and then performs a dry run on the machine before actually cutting a part. Sometimes, however, the simulation will go smoothly but the machine won’t like the program for some reason, which he refers to as crashing, but no damage to the machine occurs. “You just reset the machine after it shuts down.”

To troubleshoot a programming issue, Gallagher says he sends to the program to Flow and the machine builder’s programming specialists will determine the cause. “It’s all part of the game.”

Gallagher says Metalistics is “super busy” and doesn’t see the demand for its public art and other projects subsiding anytime soon. And if the fabricator needs more waterjet machining capacity, Metalistics will go with Flow.

Metalistics, Everett, Washington, 425/348-9377, metalistics.com.