ver the past 50 years, the U.S. industrial sector has seen a lot of heartache, with permanent factory closures and layoffs and machinery moved offshore or just scrapped. It’s heartwarming when you find a manufacturer that was most certainly bound for the dustbin of history but clawed its way back to relevance.

Skana Aluminum Co., an aluminum mill on the western shore of Lake Michigan, began life as the Aluminum Goods Manufacturing Co., which established the Mirro cookware product line in 1917. It was sold in 1983 to Newell/Rubbermaid and was shuttered in 2000.

When in 2009, the rolling mill assets became available, Thomas Testwuide Sr. and four friends came to Manitowoc, Wisconsin, to see what could be done to purchase, revitalize and operate the mill. The doors reopened in April 2010, and by early July, Skana Aluminum cast its first aluminum slab. Two years later, Skana acquired the assets of Scott Aluminum in Clarksburg, West Virginia, which included a cold mill and slitting capacity. Today, Skana Aluminum employs approximately 225 people across its two plants.

Ten years on, Testwuide continues as president and CEO; Steve Gallimore is executive vice president, sales and marketing; Kristine Raeder is CFO; and Dave Hauser is COO and vice president of operations.

According to Gallimore, the Manitowoc complex is fully integrated, with melting, casting and a hot mill, rolling slabs and converting them to hot band coils. Those coils move through cold mills both in Wisconsin and in West Virginia.

“We think of ourselves as a minimill,” says Gallimore. “We produce common alloys, grades 3003, 1100, 3004, 1350, and in 2020 we got back into 5052. That’s a big deal for us.”

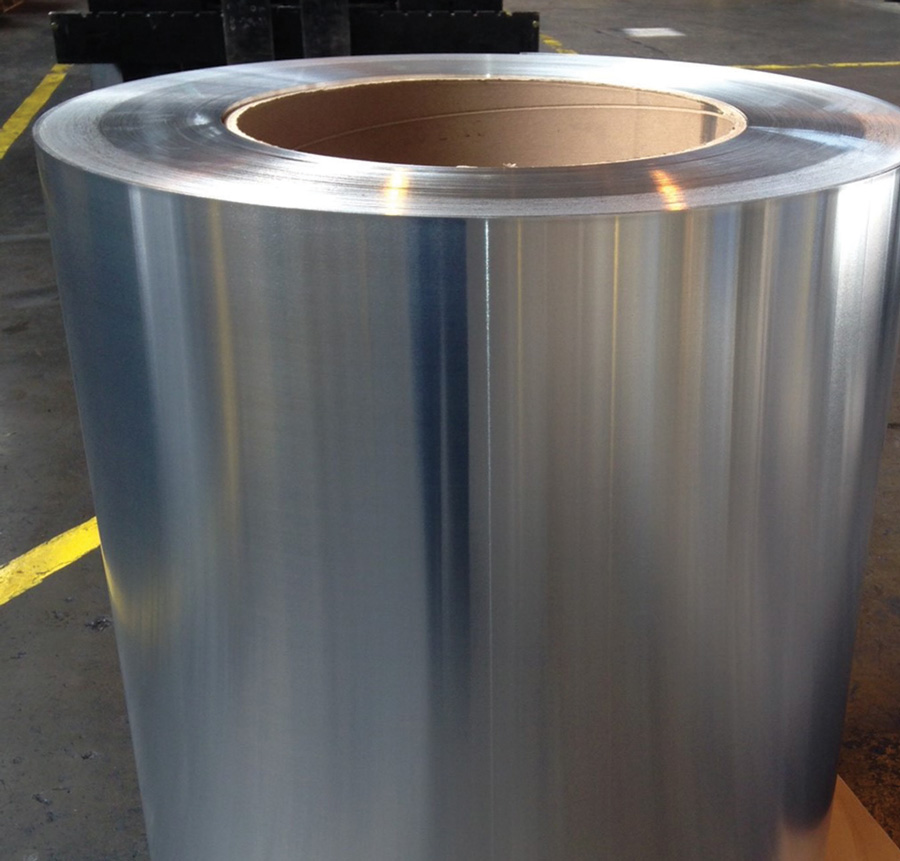

Skana ships about 80 million pounds of aluminum per year. “We support distribution and OEMs—electrical transformers, bakeware, cookware and some automotive as examples. We also offer one-side bright. And we have found markets for that.”

Gallimore concedes that gaining customer recognition and acceptance was difficult initially, considering the mill had been idled for a long while before being restarted. “We have a smaller sized coil, so it was a matter of finding the customers that accepted a smaller OD coil. Many times, machine shops prefer a smaller coil because they run what they need and pull it off their lines.

“We overcame that challenge,” he says, and then developed a laser fusing system, whereby Skana can fuse two coils together to make a bigger OD coil. “The laser fusing system was developed in house; it uses only the aluminum it is fusing.

When customers roll the larger coil, “the weld is smooth and there’s no seam. You can even stamp that part, depending on the application,” Gallimore says.

Skana Aluminum, despite its growth, continues to make custom products. “We offer slit widths and gauges in multiple sizes,” compared with the standard sizes offered by other mills. “Someone can ask us for unusual sizes, and we will deliver that for them.” Products are qualified by an in-house laboratory.

Someone can ask us for unusual sizes, and we will deliver that for them.

Someone can ask us for unusual sizes, and we will deliver that for them.

“We are just completing a two-year, $19 million expansion of our Wisconsin facility. This mill was built in 1960. Our project replaces the original furnaces and casting pit with state-of-the-art systems. We also extended the building for the new furnaces while still running the old ones,” Gallimore says.

Thorpe Technologies Inc., San Dimas, California, has built two identical tilting melt furnaces. Each has melt capacities of 54,000 pounds and will support an annual cast plan of up to 125 million pounds. “These furnaces are more energy efficient, require less maintenance and provide more uptime than older generation systems,” Gallimore notes.

The new casting pit is manufactured and installed by Wagstaff Inc., Spokane Valley, Washington. It will be fully automated with continuous lubrication, internally guided cast cylinder and in-line degassing.

Being integrated, says Gallimore, “means we can be very flexible with our product offering. We offer value-added products in house.” He cites the ability to offer circles and cut-to-length sheet up to 48 inches wide and up to 144 inches long. “We have four stamping presses with over 100 die sizes up to 48 inch. That’s an important need for many markets.”

The company can also provide tension-leveled coils for applications requiring superior shape control. Its slit coils range from 0.5 inch to 48 inches wide.

In addition to traditional pattern sizes, Skana will produce nonstandard width and length blanks, saving customers processing time and scrap. Skana also produces and processes H-Temper and O-Temper sheet and blanks.

“We are a completely domestic U.S. manufacturer, supporting American families,” says Gallimore. “We are an excellent domestic source for quality aluminum,” which ships throughout North America.

Regarding the continued renewal of a once-defunct manufacturing facility, Gallimore says, “This is a huge project and one that will make us a sustainable long-term player in the market. We are building for the future.”