hen a piece of equipment is central to a company’s operation, reliability is essential. That’s the case for Metal Supermarkets’ stores.

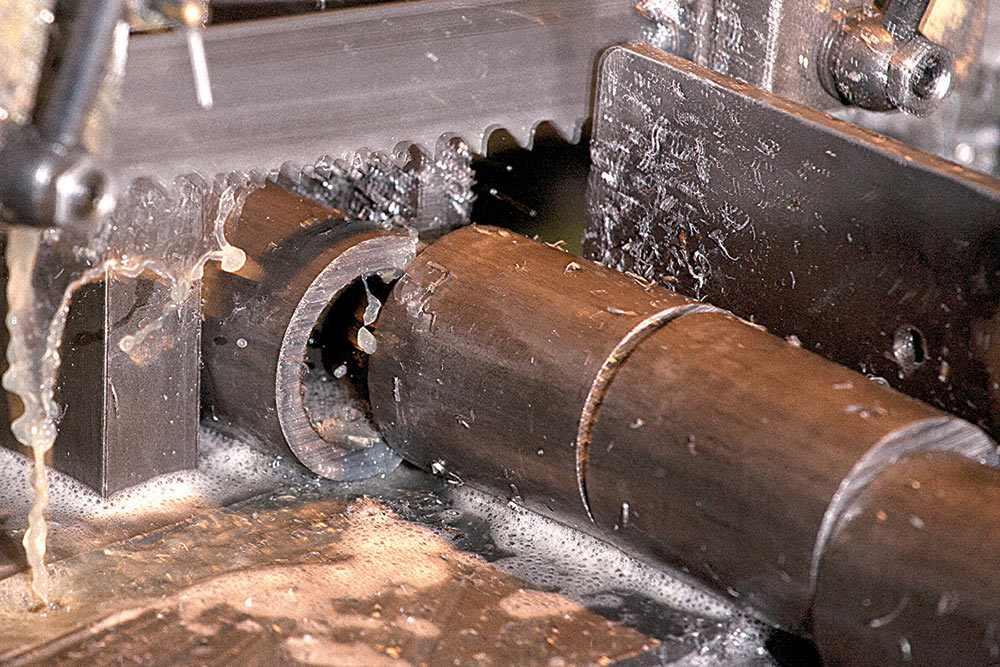

Bill Bittorf, owner of Metal Supermarkets Denver (Commerce City), opened his franchise last July and primarily uses a SH-500M semiautomatic swivel-head mitering bandsaw, which features hydraulic lifting of the saw frame and a full-stroke hydraulic vise. Built by Charlotte, North Carolina-based Cosen Saws International Inc., the machine cuts more than 8,000 types, shapes and grades of metal. The customer base includes fabricators, building maintenance personnel, trades professionals and hobbyists.

After researching more than a dozen franchise opportunities, Bittorf says Metal Supermarkets rose to the top. “After [performing] due diligence and talking with a lot of the other owners and the folks at corporate headquarters, I decided to pull the trigger and start a Metal Supermarkets franchise.”

Arminen differentiates Metal Supermarkets from conventional metal service centers based on the quantities these stores provide. “A service center would love to sell a large manufacturing facility 10,000 or 50,000 pounds of a particular product,” he says. “We sell 100 pounds of a single product or an inch of something to get the job done.”

Metal Supermarkets requires its franchise owners to purchase Cosen sawing machines, typically starting with the SH-500M, because the company has determined the equipment to be cost-effective, reliable and versatile, Arminen says. “If a saw goes down, we need someone to fix it quickly. One of the reasons for selecting Cosen is the service network they have for support.”

He also appreciated that a national sales representative for Cosen called to arrange a visit to Bittorf’s store while he was visiting Denver to attend a conference. “He dropped in, took me to the saw and talked about some of the capabilities I didn’t know it had,” Bittorf says, adding that he subsequently learned how to operate the saw more efficiently.

“I rely on the Cosen as the center of my operation,” he says. “We are using it throughout the day.”

Eric Rogers, owner of Metal Supermarkets Atlanta South, started supplying customers with cut-to-size metal in March 2019 and added a Cosen C-510MNC bandsaw early last year. The South Atlanta store also initially purchased a SH-500M automatic bandsaw, which is used to quickly cut metal for walk-in customers while they wait, whereas the other saw is for production applications or when the warehouse worker needs to multitask and saw metal while shearing and loading material. One repeat job requires 2,000 pieces of flat bar to be cut to size. “We are able to cut that pretty quickly and get that over to the customer,” Rogers says.

The automatic saw has cut workpieces up to 8 inches in diameter, while the semiautomatic has processed beams up to 14 inches wide. The store can also saw bar stock down to a diameter of 1/8 inch.

Due to his previous experience in sales and management, Rogers says he appreciates the training Cosen provided after purchasing the sawing equipment, especially the automatic unit, which requires a bit more knowledge about how the blade cuts and how to set the cutting speeds and feeds, compared with the semiautomatic saw.

I rely on the Cosen as the center of my operation.

I rely on the Cosen as the center of my operation.

The training Cosen provides complements the instruction a new store’s team receives from Metal Supermarkets. “Most of our franchisees don’t come from the metals industry,” Arminen notes. “We have two weeks of training in our stores, plus we’re down there for two weeks prior to opening on how to use the saw, the shears, things of that nature.”

“He is keeping an eye on our blades and sending [replacements]. He might send five blades because he noticed I was running low on this, this and this. It’s one thing we don’t have to do.”

Dimitrov has been running his store for almost two years, and after three months in business, he added a second saw and later purchased a third one. The store’s lineup includes a G260 production bandsaw, a G320 double-column automatic bandsaw and a C-510MNC horizontal mitering bandsaw, which enables programmable material indexing with the mitering function. “The requirement of the franchise was to have one saw, and now we have three and they don’t stop all day.”

The G260 typically cuts harder materials like stainless and other steel alloys, while the other two handle the carbon steel and aluminum, Dimitrov says. “We have different blades on different machines, so this way we can cut the harder stuff on one and the softer stuff on the others. Otherwise, you are changing blades all the time and that’s rough.”

Sawing isn’t generally considered a high-precision machining operation, but Dimitrov says he’s able to achieve tolerances as tight as 0.001 inch.

“With the support of Cosen, even over the phone and with the local representative, I wouldn’t think about another machine builder,” Dimitrov says.

However, having the needed equipment, training and support doesn’t complete the equation for running a successful Metal Supermarkets store. People are also needed, and hiring those with the required skills isn’t as easy as placing a help wanted ad. In one recent instance, Rogers made two job offerings to a candidate on the spot, but he never showed up for his first day. However, “we’ve been fortunate to have the right people at the right time,” Rogers adds, noting that it’s relatively easy to teach operators to use Cosen saws safely and productively.

Metal Supermarkets, Mississauga, Ontario, 905/362-8226, metalsupermarkets.com