he team at Plasma Systems Inc. has more than 25 years’ experience in the plasma cutting industry. Working with a variety of customers has given the company a broad understanding of how to implement the right machine for the work environment, material specifications, available shop space, budget restrictions—and even staffing considerations.

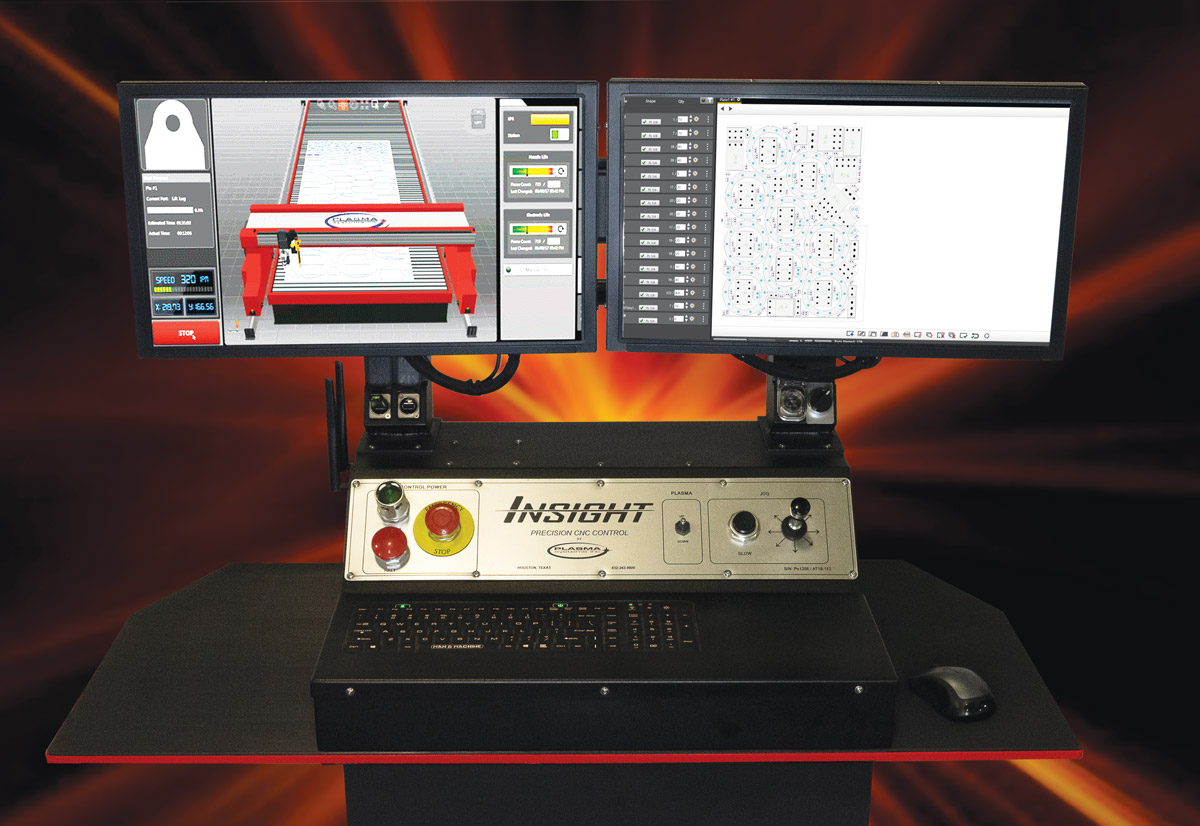

Drawing on that experience, the Houston-based company recently developed and released its new InSight controller, which features an open architecture that combines tight security with the ability to add necessary tools to the system.

“The same old controllers have been around for years—but the cutting machine capabilities have changed,” says Richard Keeton, president of Plasma Systems. “Machines needed to be more precise, easier to use and adapt to a changing market quicker. Three years ago, we partnered with Atek Automation to produce a state-of-the-art controller,” and InSight was released after a year of thorough testing.

“The idea behind the controller was to migrate toward a lights-out-type system,” Keeton says. The system also operates using laser technology to measure both distance for plate skewing and torch height. “With the laser measuring, we can automatically locate the plate while the controller can sit off the machine and receive large packets of information in real time.”

Keeton says that industrial automation is more intelligent when paired with precision plasma.

“The controller can now monitor movements in real time and make corrections. This allows for maintenance scheduling of the machine for less down time and more throughput, as well as remote monitoring of the output of the machine without being on the shop floor.” As a result, “the operator is freed up to perform part programming, nesting or more tasks other than just watching the machine run.”

Industrial automation is more intelligent when paired with precision plasma.

Industrial automation is more intelligent when paired with precision plasma.

Another sticking point with older controllers is the ability to replace components easily. On previous generations, parts were proprietary and more than likely unavailable. Because the older generation controllers embed Windows, the customer’s only option would be to buy a new controller. A simple replacement, such as for a motherboard, required an expensive special order.

For the InSight controller, all replacement parts can be purchased at big-box electronics stores, such as Best Buy or Microcenter, and then swapped out with the problematic part for a quick change that keeps the machine running. These features decrease service cost and down time.

The controller also reduces pierce times, can process structural material, handle complex beveled parts, keep track of remnants for later processing, and display the estimated time it will take to complete a part or nest.

“Most of the current controllers on the market rarely get software upgrades,” Keeton says. “The software in most of these controllers is over 15 years old. We constantly ask our customers what they would like to see in a controller, and we take that information and generate two or three major updates each year. I think it is imperative that the controller evolves to stay on the edge of new technology.”

The controller also is capable of adjusting an in-progress nest to accommodate rush jobs, skipping forward to a part, cutting it out and then going right back to where it left off, and the ability to change the kerf on the fly.

He says this customer has always relied on offline nesting to stage the machines, but several years ago the manufacturer retrofitted this equipment with the InSight controller and laser system.

“The company had just instituted a new system where the parts cut today will be welded the next day. With the new controllers, engineering just sends a list of parts to each machine, and the operator does the nesting on 50 plates. Five minutes later, he is cutting the nests.”

The client’s cutting tables, he notes, accommodate two plates end-to-end with a 12-inch gap in between.

“With the laser doing the automatic plate alignment, it takes less than three minutes to start cutting the next plate. Overall, production has increased and mistakes have decreased. Increased productivity increases the bottom line.”