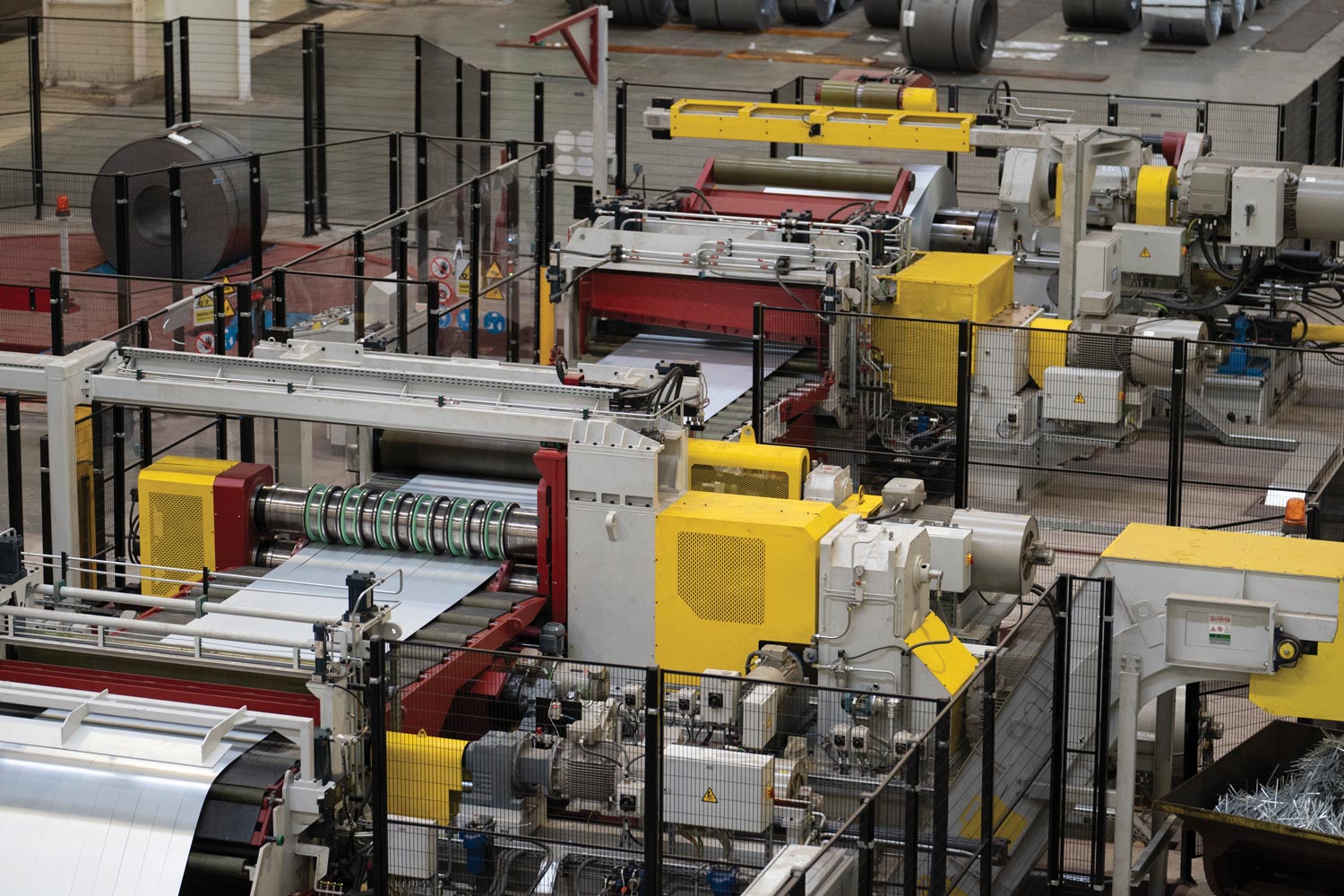

o many variables go into the process of specifying, installing and commissioning a metal processing line. For the team at Coilplus Illinois, Plainfield, the capital project to design and purchase a new slitter was time consuming, but has proved worth the effort.

The Plainfield processing center is one of 10 branches Coilplus runs across North America. After running a slitter practically full out for nearly 30 years, the team sought to widen the gauge range and grades it could slit, while moving ahead of the curve by employing robotic technology and automation.

Plant Operations Manager Paul Kacmar says the Plainfield branch was working overtime on the existing slitter, which ran master coils up to 1/8 inch thick. In late 2019, Coilplus installed a new line from Fagor Arrasate, Spain, that can slit coils up to 1/4 inch thick. The line ramped up gradually during the pandemic.

“Our parent company [based in Japan] has service centers all over the world,” says Tim Dilbeck, general manager of operations. “The service centers in Japan have had robotic knives and separators set up for decades already. We just weren’t able to bring that to the United States. I wanted to incorporate that technology.”

U.S.-based machinery builders offered to put a robot-aided line together but acknowledged it would be their first such tryout. “I didn’t want to be the guinea pig. I have done that before, and I’ve seen more failures than success. We needed this to be right and immediately productive and not spend months working bugs out,” says Dilbeck.

Eventually, Coilplus chose Fagor because it pledged to have service and support personnel on the ground in the United States. Fagor will open a technical center in Portage, Indiana, later this year.

“That level of support is extremely critical for us,” Kacmar says, in part because there are “a lot more sensors and a bigger computer running the machine. We must know not only what the machine is doing but we also have a second sensor confirm that the first sensor is accurate and is not failing.”

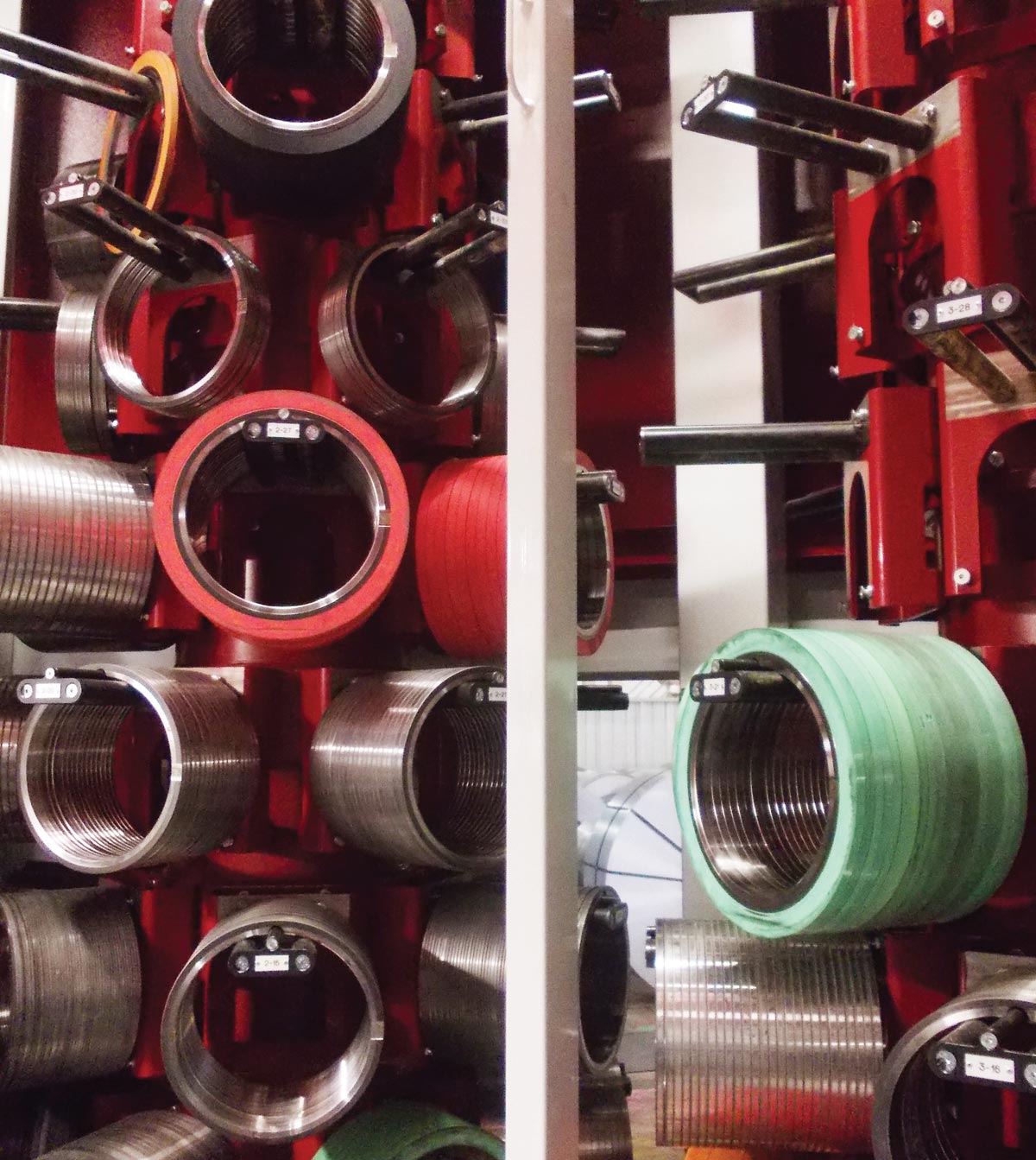

The key difference between what Coilplus Illinois has and what all other U.S. metal processors have is robotic technology on the slitter head.

Each slitter knife and spacer is etched with a three-dimensional label that is read by the robot. As the robot maneuvers inside a tower stocked with knives, it can verify that it is selecting the exact right tooling for the job.

“There is a verification that this is the proper tool for this setup. Sometimes, when a human handles the tooling, the blades will bang together and may get dinged,” says Kacmar. “The robot does not mishandle tools. It manages them perfectly every time, mates them perfectly every time. That reduces our tool maintenance.”

The robot is also equipped with a knife edge assessment tool. A laser scans the edge of the knife, as the knife rotates 360 degrees. It ranks any imperfections. A knife with zero imperfections can be used for the most critical applications. Knives that have a few more defects on the edges, or that are not as sharp, can be used on lesser applications, says Dilbeck. “We can know the quality of the edge on each specific knife and how each knife should be used. The robot selects the knives for the purpose.”

Since the line was installed, Coilplus has not sent any knives out for maintenance. So the assessment program has extended the life of the tooling.

To do a good job, slitter operators “must have finesse,” says Peter Swenson, metals division sales manager for Fagor Arrasate. When checking a knife’s sharpness, an operator will “run a thumbnail around the edge of the blade,” and check for surface imperfections by eye. In trying to clean a tool off, the operator will wipe off any debris with a glove or rag.

Associated with Coilplus’ Fagor line is a wash machine for the tools. “It uses an ultrasonic cleaning system with an alkaline detergent. The guys are not picking the tools up, which eliminates the possibility of damage. That also eliminates repetitive motion,” which can cause operator injury over time.

“Coilplus is the first in the U.S. to have this particular technology. It is ahead of the curve,” Swenson says.

The company also installed a camera to measure slit widths. “We no longer have our people measure the width; the camera does it. It saves us time; it is safer,” says Dilbeck. “The system takes measurements several times per second; it measures the coil from beginning to end and gives us a report. It covers every inch of the coil. It is a helpful tool.”

As the master coil is slit, the narrow ribbons of metal are separated to prevent tangling while being rewound into individual coils. Historically, tooling separators were loaded manually.

Often, a first-shift operator will do that one way while the second-shift operator will load the separators slightly differently, even on the same order. “So there is some subjectivity,” says Kacmar.

the robot manages the tools and mates them perfectly every time.

the robot manages the tools and mates them perfectly every time.

At Coilplus, that process is now automated “so separators are loaded the same way every time. We can modify the program, make minor adjustments as needed. If we find we must make a modification for a particular order, we can make it, and it always happens the same way from then on,” he says.

The computer that runs the slitter is connected to Coilplus’ ERP system so when the team writes a work order, that information for sizes and tolerances is all transmitted to the operations computer. “The guys at the machine have everything already preset when they select the order for the coil they are processing,” notes Kacmar. “They don’t have to do any additional calculations.”

Coilplus processes metal for end markets such as HVAC, building products, appliances, automotive, agricultural equipment and electronic enclosures.

“The new slitter doubles our capacity. It gets us into ultra-high-strength steels [UHSS] we couldn’t do before, and that opens the door for additional automotive growth in light gauges,” according to Dilbeck. “You will hear ‘lightweight’ all day, every day, everywhere. UHSS is the direction consumers have chosen, so if we are able to run 180,000 tensile strength versus our older line, running 50,000, that opens a door.”

The Fagor line also opens a door for heavy-gauge stamping, using hot-rolled pickled and oiled. “The new slitter cuts material twice as thick. We didn’t have that ability before.” Dilbeck predicts that the Fagor slitter will also help Coilplus develop and grow its handling of stainless products.

At one time, Kacmar says, high-strength steels were the exception. “Now, it’s the rule.”

Bottom line, “The more coils we process, the more money we make,” says Dilbeck, so the investment in hundreds of hours of engineering and design, installation, integration, commissioning and test runs will be returned. “We have markedly higher productivity than the competition. The machine is doing the work.”

Coilplus Illinois, Plainfield, 815/436-3999, coilplus.com.

Fagor Arrasate, Willowbrook, Illinois, 630/670-6455, fagorarrasate.com.