t first glance, packaging for metal products seems uncomplicated—wood skids and pallets, dunnage, shrink wrap—mainstays at the ready to receive loads of steel, copper, etc., and carry them to their destinations. But packaging is a process where companies can shrink costs if they switch to materials that better protect products and contribute to a more efficiently loaded truck.

“Our customers’ products are valuable, so it makes sense that the packaging used works without fail to ensure satisfaction and an uninterrupted supply chain,” says Dave Watson, director of national sales for UFP Industrial, Grand Rapids, Michigan. UFP Industrial is part of UFP Industries, which manufactures, distributes and sells a wide variety of value-added products used in residential and commercial construction, packaging and other industrial applications worldwide.

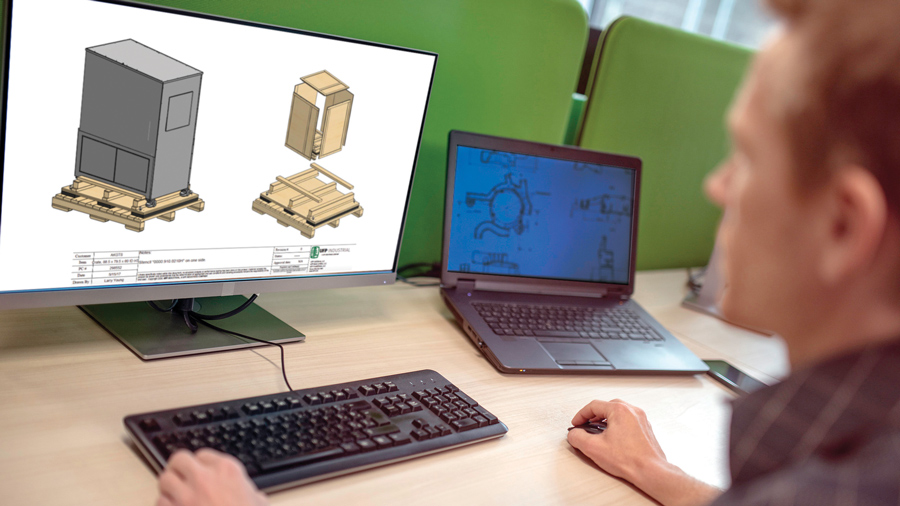

“We have design specialists that can help configure a solution that meets protection and weight requirements,” says Watson. “Our designers can also help customers lay out a truck” to maximize the weight requirements and efficiency.

UFP Industrial can also offer metals companies innovative solutions, like BarrierWood Corrosion Resistant Lumber (CRL), which was created to replace hardwood lumber that often is wrapped in VCI film and plastic sleeves to prevent corrosion on steel. BarrierWood CRL is machined to a V-groove that increases air flow at the point of contact with the steel. Additionally, the lumber is treated with a colored topical solution that contains a chemical compound, which helps to prevent corrosion in transit.

packaging needs to work [well] to ensure an uninterrupted supply chain.

packaging needs to work [well] to ensure an uninterrupted supply chain.

UFP Industrial

In addition to the money saved on quality complaints and excess material, BarrierWood can contribute to a safer warehouse environment because it’s 38 percent lighter than commonly used hardwood lumber components. “Ergonomically, you’re using a substantially lighter product that doesn’t sacrifice the safety of your product,” Bilbrough says, which reduces strain on employees.

“UFP sales teams, which include people from engineering, design and purchasing, can travel to your facility to sit down and hear your pain points,” Watson says. “They can then come up with a solution that meets those needs.” UFP Industrial makes it a point to deliver nuanced strategies that are not over-designed and expensive or under-designed and unreliable.

“We also strive to use species indigenous to the customer’s area of the country,” Watson comments. “If they’re in the South, we often choose Southern yellow pine. In the Northeast, it might be spruce. The steel industry tends to deal with hardwood. We have hardwood capabilities, but hardwood is very heavy. Shipping it to customers is costly. And, many times, hardwood is not dried at the mill, which adds a process. When you use Southern yellow pine, it’s being dried at the mill, saving a step.”

With current lumber prices spiking at levels 374 percent higher than last year, according to Wells Fargo, now is a good time to re-evaluate packaging options. Watson and Bilbrough say that companies often are reluctant to switch materials, believing for instance that hardwood is stronger than softwood—even though some mixed hardwoods are not as strong as softwood, despite their greater weight.

“Right now, because of the constrained availability of lumber, some companies are having to make changes to the wood species they are using,” Watson says. “And I think we’ll see more companies trying out different solutions to ensure that there are no shipping disruptions.”