arker Steel Co. distributes a wide variety of metals in metric sizes to customers across North America and is highly focused on meeting its commitment to source customers’ critical needs.

The company, based in Toledo and Maumee, Ohio, has designed all steps in the procurement process to make it easy for its customers to purchase and receive their orders with minimal time and hassle, says President Jerry Hidalgo.

“We put a major emphasis on shipping received orders on the same day each order is placed. In most cases, we succeed in doing so,” he says. Internal statistics show that over 99 percent of delivery promises are met. Parker can achieve this level of performance because every employee is willing to make “extraordinary efforts” to ensure customer commitments are met.

That duty is shared by Parker’s supplier base. Its network of international and domestic suppliers “are an important part of the team.” The purchasing department has developed a group of strong, reliable suppliers. Because the metric system is the standard in Europe, the majority of Parker’s product lines are sourced there. The company has built the largest inventory of metric metal products in the United States, with over 6,000 line items in stock.

“We sell across all industries,” says Hidalgo. “Any company that has a machine that was designed or built in Europe and that was built to metric dimensions, is a potential customer. The replacement parts have to be metric. Having a very diverse customer base helps keep our business very stable.”

Parker continually seeks out additional metric products to add to its offerings. “If more than one customer asks for a specific product that is not offered by Parker, that product will be researched and probably added to our inventory.”

Customer satisfaction is measured on a regular basis through surveys, and on a scale of 0 to 5, ratings typically average 4.8.

“We have two different surveys. One is for customers that place larger orders. We send that out monthly. The other we do biannually, and these are sent to a sampling of customers; we change the samples every time.” One biannual survey will target customers placing small orders, while the next will target those placing average order sizes “so we get a response from a mix of customers. The results from survey to survey are very consistent,” Hidalgo says. “I feel very good that we maintain that level of customer satisfaction.”

U.S. Customs and Border Protection set this program up following 9/11. “The objective is to make shipments coming in safe, to make sure no bombs or contraband are hidden in shipping containers from overseas. For us, it makes sense to be part of the program for our own safety, and it lets customers know we are a safer supplier, a trusted partner.

“In the event we did have a terrorist attack that would shut down the flow of goods,” Hidalgo says, “we would be high on the list once import traffic began again.”

“Our sideloaders go up very high, 23 feet, to place material in the racks. We have cameras on the sideloaders so we can visually see where we are placing the material, so it’s a safe maneuver.

“It was really crucial over the last year to have inventory,” Hidalgo notes. “We had suppliers, especially in northern Italy, who were shut down by the pandemic, and we couldn’t get any new material for a short time.

Later this year, the company will build a new office block within its main warehouse and will use the space for small-package shipping, offices, lunchroom, meeting and training facilities. “This expanded area also makes it easier to maintain social distancing in the future,” Hidalgo notes.

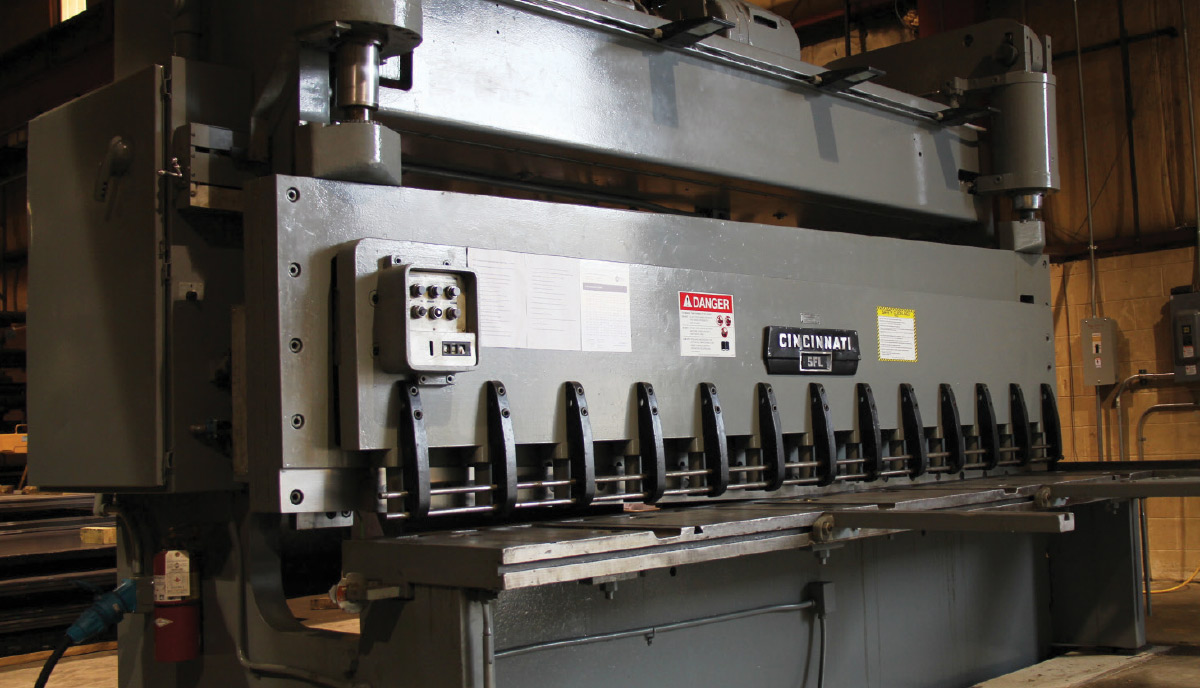

Also, Parker Steel will purchase and install a CNC laser cutting machine for sheet and plate during 2021.

“We have a shear that we use to cut all our plate but the shear can distort the flatness of thin material and it is not as precise as some customers want,” Hidalgo explains. “The laser cutting increases the precision and eliminates the difficulty with flat material. We will make the purchase during the second half and will train three to four operators to run it.”

all our suppliers are operating again but demand is so high that they have extended lead times.

all our suppliers are operating again but demand is so high that they have extended lead times.

Overall, the better the manufacturing sector does, “the better it is for our business. Strong manufacturing is important for America. Anything the government can do to help U.S. manufacturing is welcomed.”

Hidalgo says the standards and procedures that Parker Steel employs is “what makes us tick. It raises our level of quality and performance. It’s important to who we are. It allows no shortcuts.”

He looks forward to the future. “We will search for additional metric products to carry; we will stick with the base metals but we will expand types and shapes. We may someday expand to other areas, especially as customers want different products.”