New Products

STACKING

Model made for surface- and edge-critical blanks

The Edge Stacker is designed to transport blanks via an overhead conveyor system and precisely drop them into ice cube-shaped stacks, regardless of the end use. This stacking system was specifically designed for blanking or cut-to-length lines producing surface-sensitive steel, surface-sensitive aluminum, or blanks for laser welding. The ability to maintain premium edge quality is also a significant feature of this design. The Edge Stacker is available as a single or double station stacker that can be equipped with either switchable permanent magnets, vacuum capability or a hybrid version that includes both.

Automatic Feed Co., Napoleon, Ohio, 419/592-0050, automaticfeed.com.

SOFTWARE

Software designed to improve productivity

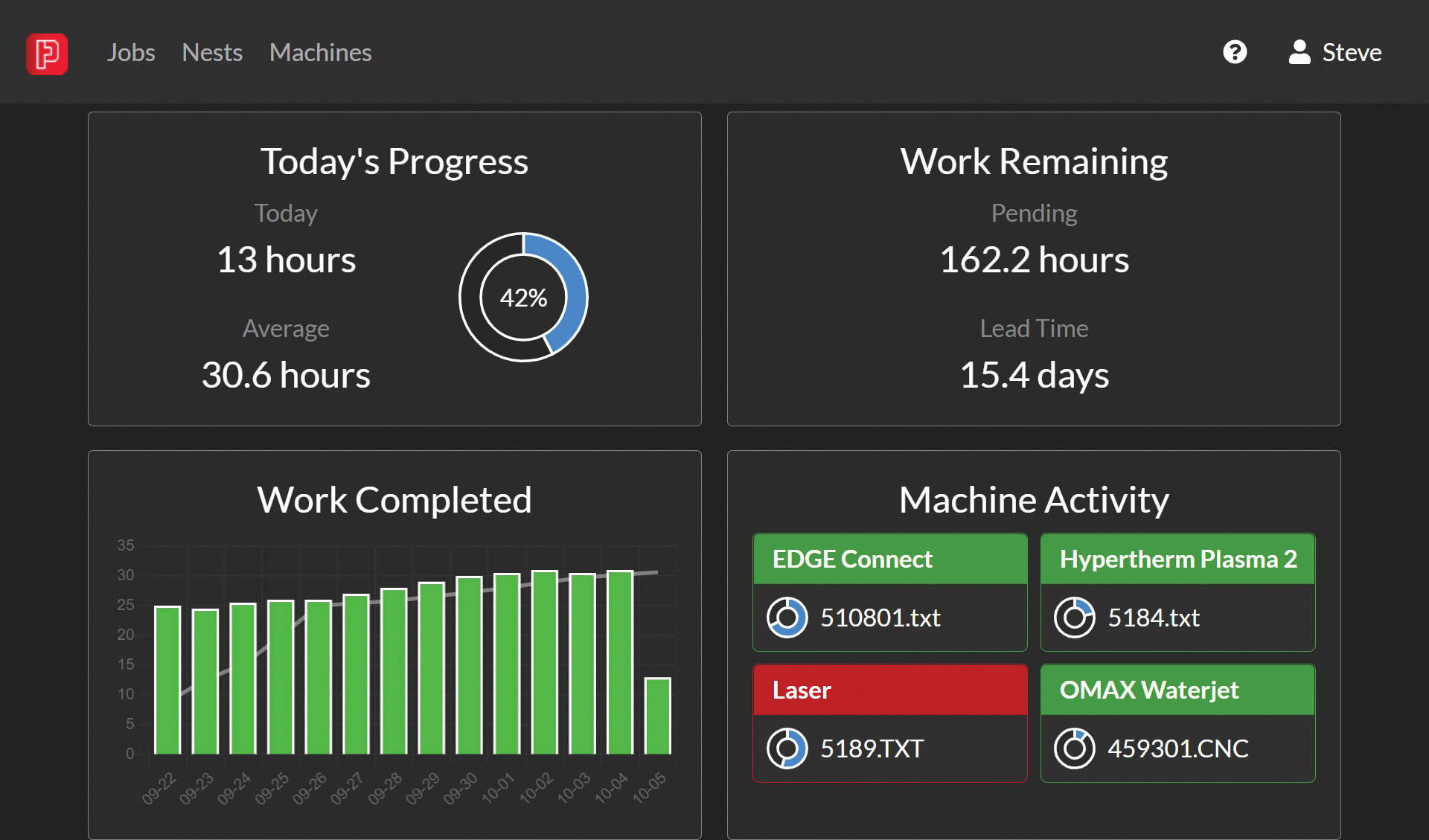

Hypertherm has released Production Manager, an optional module for its ProNest CAD/CAM nesting software. This web-based module is designed to improve productivity, maximize machine up-time, boost on-time delivery and increase material utilization. Production Manager seamlessly integrates with Hypertherm’s Edge Connect CNC to automatically capture machine data without operator intervention.

Hypertherm, Hanover, New Hampshire, 603/643-3441, hypertherm.com.

WELDING

Controlling gas pressure better

The 355-2 Flowmeter Regulator is pre-set to a low compensated pressure of 20 PSIG, which allows a higher flow rate. This low pressure reduces surge and reduces the amount of gas wasted, while having enough compensation to eliminate any issues in the gun and machine. The flowmeter regulator features an internal filter and PTFE Teflon seat. This type of flow meter regulator is highly recommended for MIG welding of large or thick materials. The model features a durable, easy-to-read flow tube and cover. The flow tube and float are easily changed for different gases.

Harris Products Group, Mason, Ohio, 513/754-2000, harrisproductsgroup.com.

more products: modernmetals.com

SOFTWARE

App for portable, fast weld inspection

The WeldSight Remote Connect app for the OmniScan X3 phased-array flaw detector streamlines weld inspections because users can perform every step via WeldSight software on a PC or laptop. Combined with Olympus scanners and probes, this phased-array ultrasonic testing solution minimizes manufacturing delays common with non-destructive testing methods. With the app downloaded on an OmniScan X3 flaw detector, the user can control the unit using WeldSight software on a connected computer. The app paves the way for high-productivity, off-the-shelf weld inspection solutions by exploiting both the powerful PAUT and TOFD data acquisition of the flaw detector, and the advanced functionalities and customizable user interface of WeldSight.

Olympus, Waltham, Massachusetts, olympus-ims.com.