We’re relentlessly committed to passionate customer service, offering versatile operations and the industries’ most expansive national footprint.

Come ride the VORTEQ wave of momentum for your coil coating needs! Let’s get started at vorteqcoil.com

Features

newly seated Congress, a changing of the guard within the Congressional Steel Caucus and the long-delayed political effort to finance nationwide infrastructure modernization are among the top-of-mind topics for the new president and CEO of the American Iron and Steel Institute.

“We are excited about the opportunities that a new Congress and administration present,” says Kevin Dempsey, who succeeded Thomas Gibson in the role. Dempsey had served as AISI’s senior vice president for public policy and general counsel since 2009.

“There are big challenges for the country, like beating COVID, before getting the economy running. The steel industry has supported in every way possible [any chance] to be part of the solution in beating COVID.”

Coil processor adds embossing line

LVD Strippit, Akron, Ohio, 716/542-4511, lvdgroup.com.

eing essential to the infrastructure of manufacturing and being able to count on a government program to shore up payroll, toll processors pulled back from the brink of crisis in the last months of 2020. Executives express a cautious confidence that a recovery—for their businesses and the economy writ large—will be realized.

The recovery in demand from customers of Andes Coil Processors, Gary, Indiana, occurred fairly rapidly during the second half of 2020, says Howard Pena, president and partner. “We started off 2020 with a record first quarter. January to March, we were well above projections. Q2 came in at about 70 percent of our plan. Then we experienced [revenues of] 80 to 85 percent of plan in Q3. In October,” he says, “Andes saw another phenomenal month; we bounced back. But November and December are typically softer.”

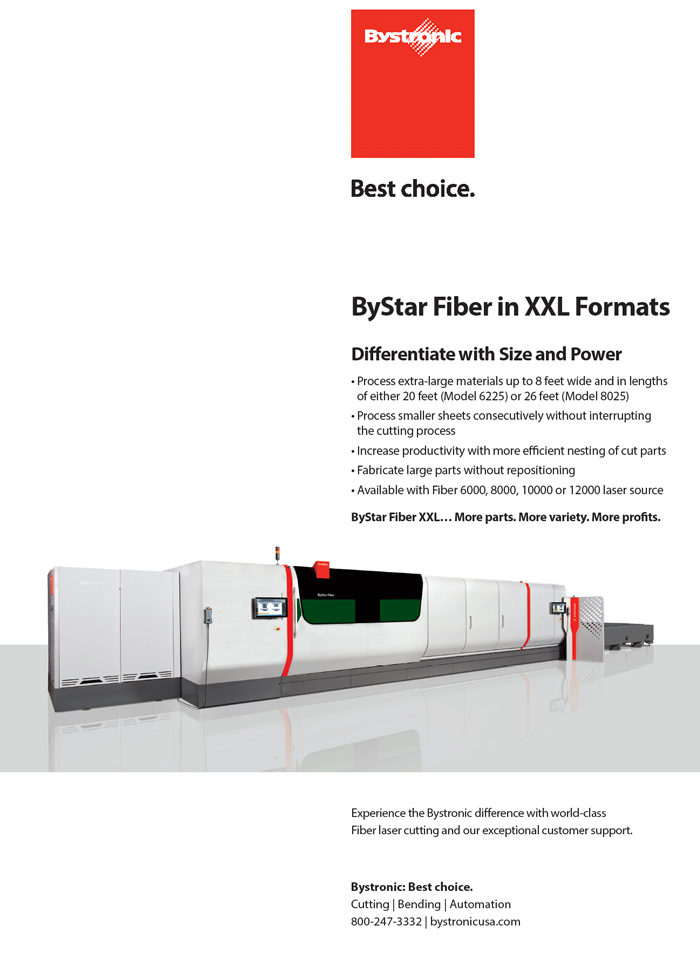

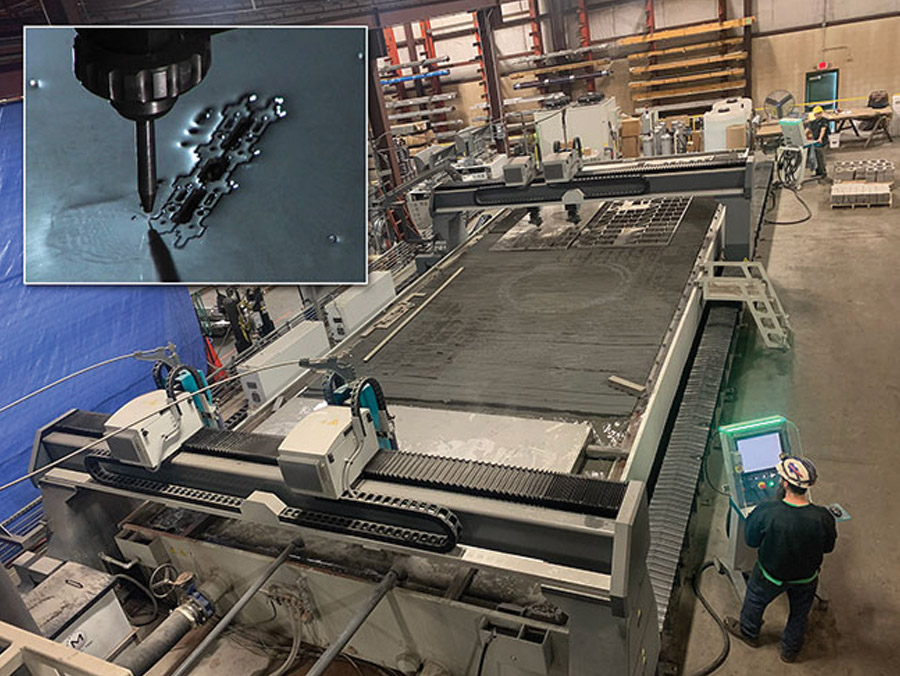

utting parts out of extra-large sheets and plates has many benefits, including more efficient nesting and fewer touches throughout the process. However, moving these big, heavy pieces of metal is a challenge, requiring systems that have superior cutting capabilities plus top-notch material handling. For McNeilus Steel’s Morristown, Tennessee, facility, a partnership with Hoffman Estates, Illinois-based Bystronic has allowed the distributor to maximize large-format cutting.

A longtime Bystronic customer, McNeilus employs 700 employees across four warehouses, with its headquarters in Dodge Center, Minnesota. The 100,000-square-foot Tennessee operation is the newest addition to the network.

“We hadn’t expanded geographically in about 10 years,” since opening a warehouse in Fond du Lac, Wisconsin, in 2009, says David Graham, general manager of the Morristown location. “Because the steel industry, including many new mills and a lot of our current vendors, is starting to congregate in the Southeast, it made sense to have a location in East Tennessee.”

For a roofing system that echoed the original material, new metal had to be historic in finish, profile and installation technique.

For a roofing system that echoed the original material, new metal had to be historic in finish, profile and installation technique.

ransferred from the U.S. Air Force to a volunteer group in 1994, Wings Over the Rockies Air & Space Museum is located in Hangar No. 1 of the former Lowry Air Force Base in Denver. The 182,000-square-foot museum houses iconic aircraft, space vehicles, artifacts, military uniforms and more.

Visitors can experience flight simulators and participate in educational programs and other museum-sponsored events. Each year, the museum welcomes about 160,000 people.

Installed in 1938, the 20-gauge corrugated metal roof on the airplane hangar performed well but had reached its useful life and required replacement. The structure was retrofitted with 92,400 square feet of curved standing-seam roofing. The roof also features ColorGard by S-5!, a snow guard solution made for standing seam metal roofs. This feature is especially critical to have in the Rocky Mountain region.

The challenge was to remove and replace the structure during winter while keeping the museum open. Adding to the difficulty was the shape and height of the roof—curved and more than 100 feet off the ground with a circumference measurement from eave-to-eave over the top of the barrel at 308 linear feet.

For a roofing system that echoed the original material, new metal had to be historic in finish, profile and installation technique.

For a roofing system that echoed the original material, new metal had to be historic in finish, profile and installation technique.

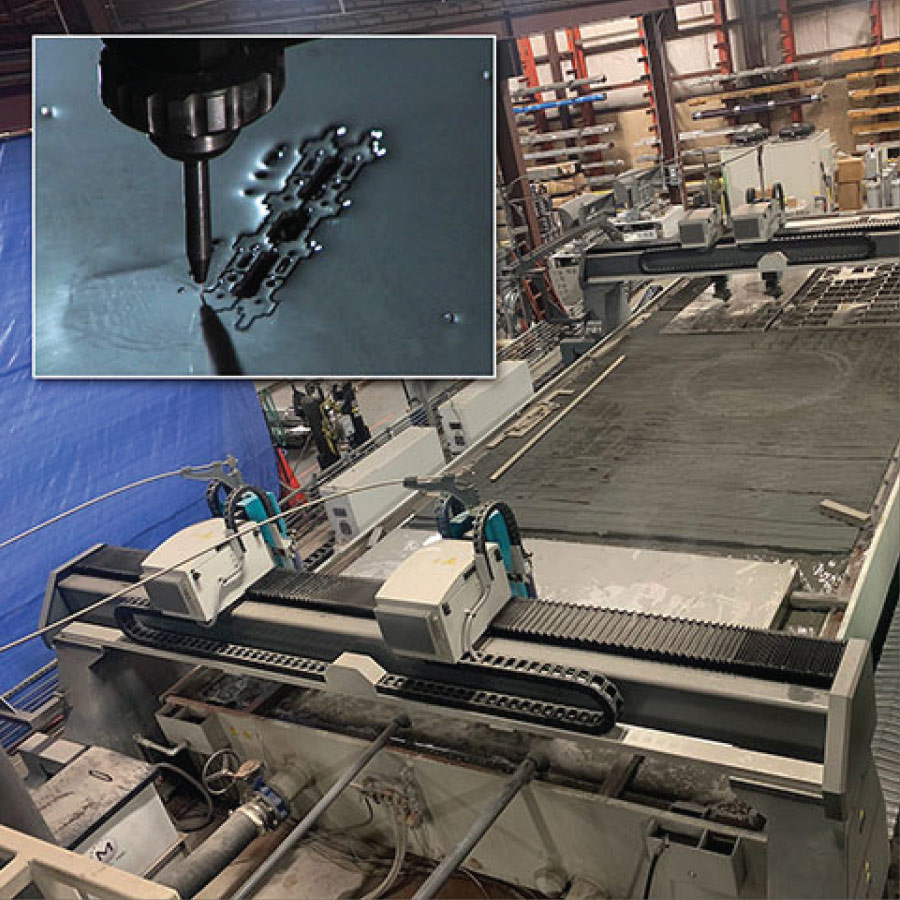

aunched in 2003 and based in Akron, Ohio, American Utility Processing (AUP) works with ferrous and nonferrous coil, sheet and plate. It performs leveling, shape correction, buffing and other services for a range of industries that include trailer, tanker, marine, rail and aerospace. The company operates a 100,000-square-foot plant and recently expanded its capabilities with a wide, heavy gauge leveler.

The secret to success can depend on various factors. For some it is a game-changing product, while others rely on a particularly broad clientele. For AUP, it is sheer presence as well as being noticed.

“We have been here for quite a while, and we offer a broad range of services. The industry found us and we responded,” says Rich Kmiecik, chief operating officer for American Utility Processing.

ool steels are carbon and alloy steels that are well-suited to shaping other materials. Their suitability comes from their hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures.

Working with hard, tough alloys requires other tools that are even harder and more resistant to breakage and erosion. When Precision Marshall Steel sought to reduce downtime due to frequent band saw blade changes and to lower the amount of man hours needed to operate its saws, the company learned about The M. K. Morse Co.’s newest blade, Jawbreaker.

“Jawbreaker is designed to cut superalloys and other very hard-to-cut materials,” says Bruce Woodruff, marketing director for Morse. “It takes advantage of two innovations. The first is patented KerfLock technology,” Sekhar Rakurty, head of Morse research, explains. “Most band saw blades create the kerf by bending the teeth side to side. Premature tooth wear can result as the bend relaxes through the life of the blade.”

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.modernmetals.com

312/654-2309, Fax: 312/654-2323

mdalexander@modernmetals.com

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@modernmetals.com

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Oklahoma, Pennsylvania, South Carolina, South Dakota, Tennessee, Texas

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@modernmetals.com

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@modernmetals.com

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@modernmetals.com

Modern Metals® (ISSN 0026-8127, USPS 357-640) January 2021, Vol. 77, No. 1 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2021 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Modern Metals® (ISSN 0026-8127, USPS 357-640) January 2021, Vol. 77, No. 1 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2021 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.