New Products

HYDRAULIC PRESSES

Pre-engineered machines are configurable

Pre-engineered Ascent presses can reduce cost and lead time by up to 50 percent compared to custom presses without sacrificing quality or performance. With models ranging from 30 to 500 tons and 21 different frame sizes, the Ascent line can suit manufacturers and jobs shops of every size. Every Ascent press features a unitized gib-guided frame, which provides superior guidance and rigidity. Speed, stroke, daylight and shut height are fully configurable to each customer’s exact needs, while options for heated platens, HPU configurations, and safety equipment add to the line’s flexibility.

Beckwood Press Co., St. Louis, 800/737-0111, beckwoodpress.com.

WELDING

Welding power sources enabled in the cloud

ESAB’s Aristo 4004i Pulse, Aristo 5000i and Aristo U5000i welding power sources are sold exclusively as WeldCloud-enabled systems. WeldCloud is a suite of online data management applications that enables users to improve operational efficiency by monitoring, capturing, tracking and analyzing data to make intelligent decisions based on accurate information. WeldCloud-enabled machines feature an embedded communication module that digitally connects the machine to WeldCloud via WiFi.

ESAB Welding & Cutting Products, Annapolis Junction, Maryland, 800/372-2123, esabna.com.

PLASMA

Upgrade Powermax style consumables

HelioCut is a patent-pending consumable upgrade for Powermax 45XP, Powermax 65 and Powermax 85 plasma cutting machines. This drop-in replacement for costly factory consumables saves cash and provides higher material yields. HelioCut’s patent-pending design lowers consumable wear, increases lifespan and allows for an improved current path for the electrode. The motionless electrode creates a stronger, more secure connection to the torch. This translates into fewer consumable changes and more uptime.

American Torch Tip, Brandenton, Florida, 800/342-8477, americantorchtip.com.

LASER TECHNOLOGY

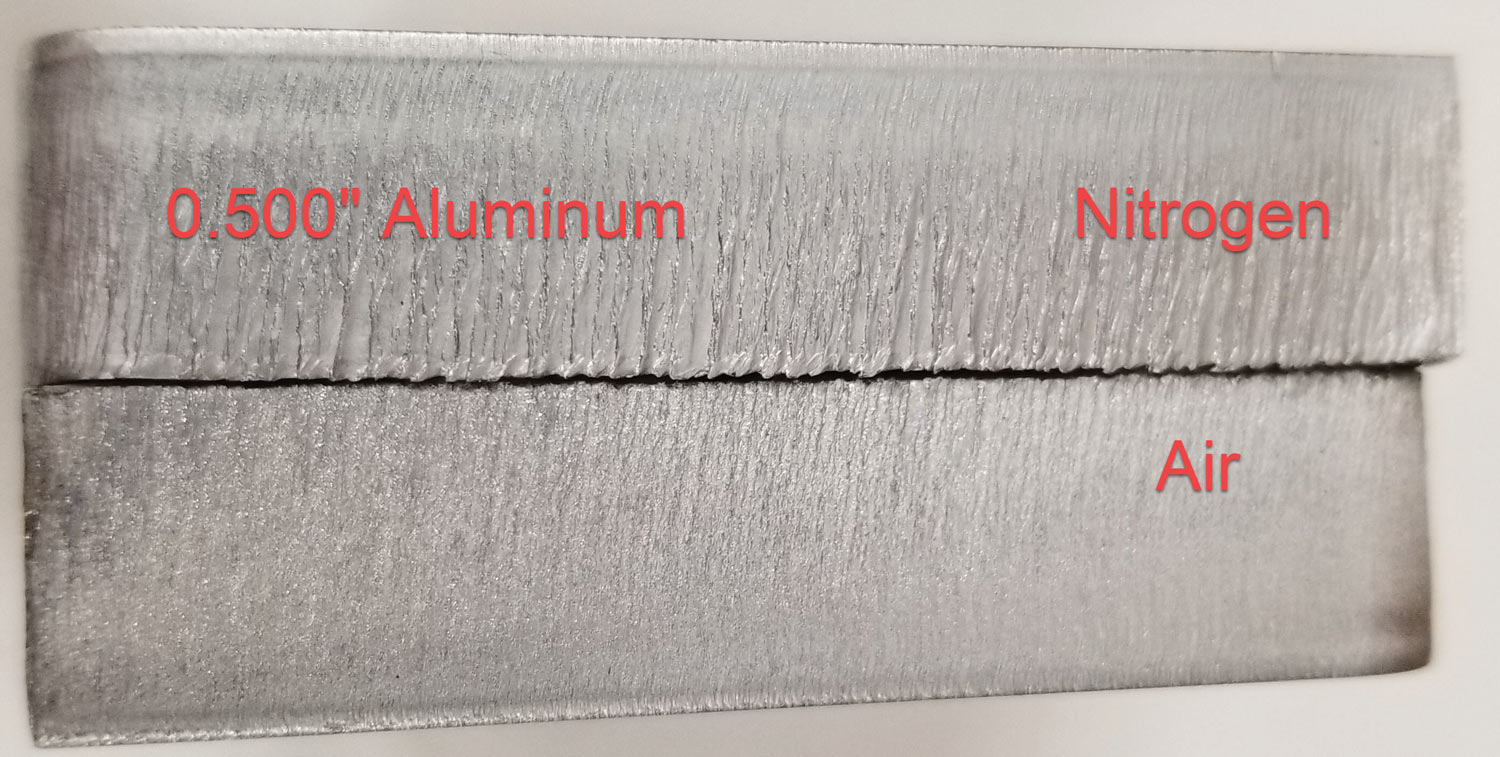

Compressed air capability added

High-pressure dry air can be used as an assist gas on all of BLM Group USA’s flat sheet and tube laser cutting systems. Systems using compressed air can achieve faster speeds, improved cutting and smoother edge quality, especially in aluminum applications. This new option enables users to choose the gas best suited for their particular material and application. When used in aluminum applications, high pressure dry air produces virtually dross-free cuts while gaining up to 150 percent increases in speed on 1/8 in. thick aluminum. Compressed air can also be an appropriate choice for carbon steel applications, where it delivers a lower cost yet provides speeds comparable to nitrogen.

BLM Group USA, Novi, Michigan, 248/560-0080, blmgroup.com.

more products: modernmetals.com