newproducts

Force software solutions are now interchangeable

A flexible selection architecture enables the range of Starrett force and material testing software programs to be compatible with its different test frame series. This interchangeable system architecture increases application versatility, providing users a wider range of solution options from basic to advanced, for their specific force and material testing needs. Starrett L2, S2, L2 Plus, and L3 software are compatible and interchangeable with all Starrett Frame/Stands Series (FMM, FMS, FMD, MMS, MMD). In addition, Starrett L1 and S1 software is compatible with FMM Series Frames.

L.S. Starrett Co., Athol, Massachusetts, 978/249-3551, www.starrett.com.

L.S. Starrett Co., Athol, Massachusetts, 978/249-3551, www.starrett.com.

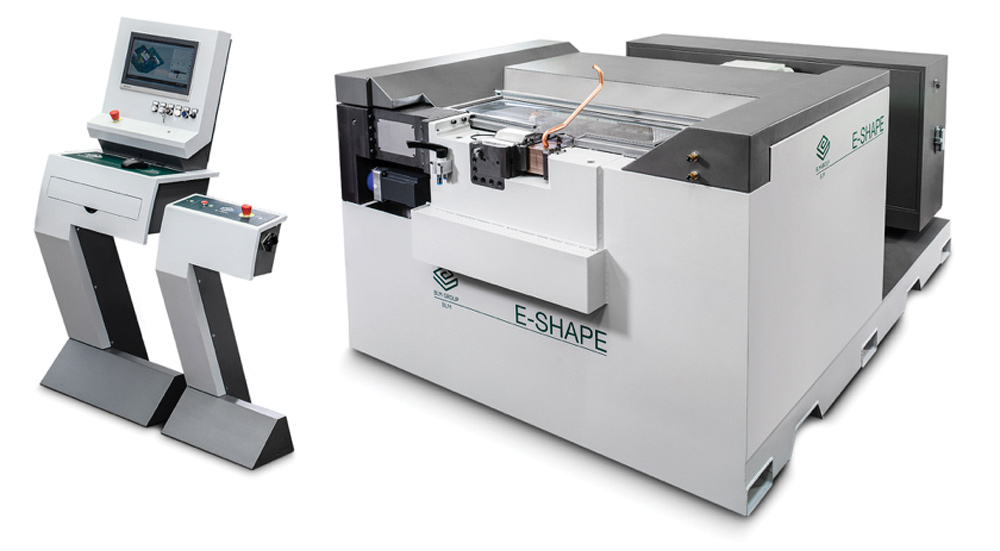

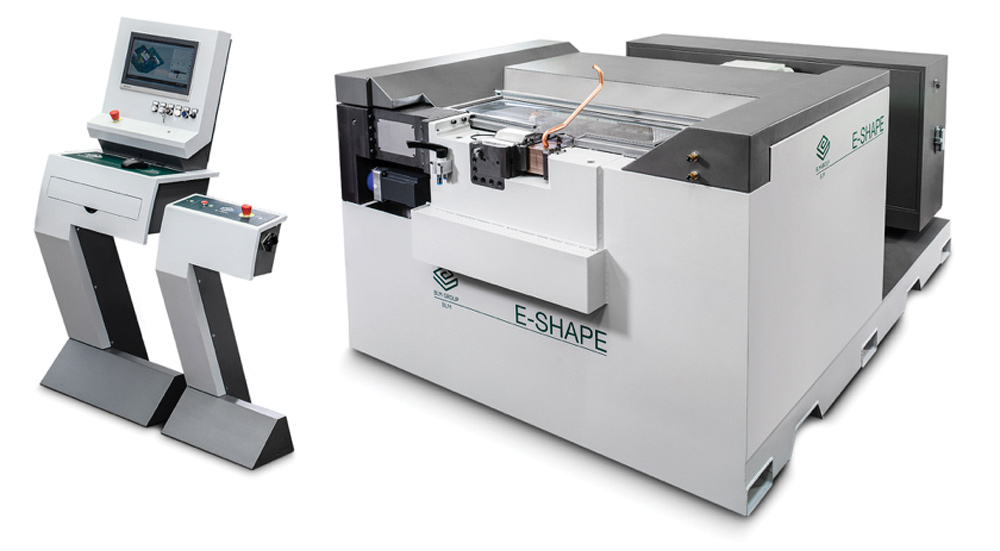

Tube forming machine, punch table combined

The E-Shape is a compact, all-electric CNC tube end forming machine with a punch table that works horizontally—eliminating interference from overhead structures. Set up for 10 processing stations, the E-Shape can be freely equipped with ram stations, rotary and/or cutting tools, enabling users to configure the machine in a way that best meets their job needs. Offering 10 tons of force, the E-Shape yields quality complex shapes and end forming in thick-walled materials or stainless steel. It can perform tapering, flaring, closing, facing, cutting and more to produce repeatable end forms, finish and quality.

BLM Group USA, Wixom, Michigan, 248/560-0080, www.blmgroup.com.

BLM Group USA, Wixom, Michigan, 248/560-0080, www.blmgroup.com.

Tube forming machine, punch table combined

The E-Shape is a compact, all-electric CNC tube end forming machine with a punch table that works horizontally—eliminating interference from overhead structures. Set up for 10 processing stations, the E-Shape can be freely equipped with ram stations, rotary and/or cutting tools, enabling users to configure the machine in a way that best meets their job needs. Offering 10 tons of force, the E-Shape yields quality complex shapes and end forming in thick-walled materials or stainless steel. It can perform tapering, flaring, closing, facing, cutting and more to produce repeatable end forms, finish and quality.

BLM Group USA, Wixom, Michigan, 248/560-0080, www.blmgroup.com.

BLM Group USA, Wixom, Michigan, 248/560-0080, www.blmgroup.com.

Blades engineered for faster cutting

The Max Efficiency circular saw blades are recommended for cutting steel from 1/16-inch to 3/16-inch thick and are designed to deliver over 55 percent more cuts per charge at a rate of over 65 percent faster speed than standard blades. A new tooth design allows for optimal, efficient cutting. The concave shaped carbide teeth and a thinner kerf allows the cut metal to be extracted more efficiently. The tips also help the blade cut smoother and straighter. When paired with cordless tools, Max Efficiency saw blades provide longer run times and faster cutting.

Makita U.S.A. Inc., La Mirada, California, 714/522-8088, www.makitatools.com.

Makita U.S.A. Inc., La Mirada, California, 714/522-8088, www.makitatools.com.

Blades are wear and heat resistant

For heavy-duty cutting applications, Steelmax Cermet-tipped saw blades offer superior wear and heat resistance for long cutting life. These blades feature a super-thin kerf for fast, efficient cutting and laser-cut stabilizer slots that reduce noise and vibration. Steelmax’s proprietary blade geometry, incorporating wide and shallow tooth pockets, combined with its Triple Chip Grind, provide speed and durability for clean, burr-free cuts in even the hardest alloys.

Steelmax Tools LLC, Centennial, Colorado, 303/690-9146, www.steelmax.com.

Steelmax Tools LLC, Centennial, Colorado, 303/690-9146, www.steelmax.com.

See more

See more