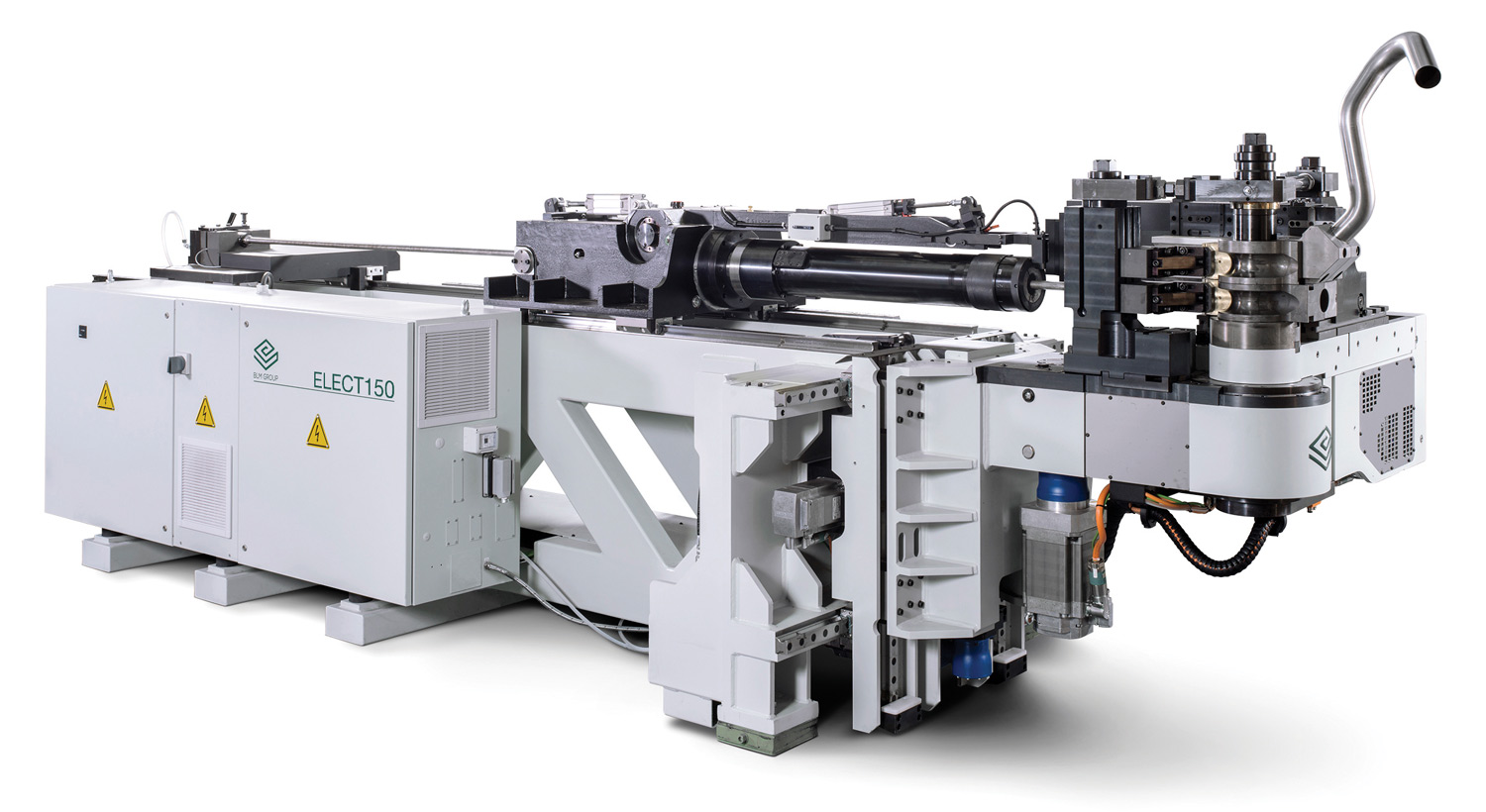

BLM Group has added of left-hand configuration capability to its Elect 102, 130 and 150 bender models. Fabricators processing tubes and pipes up to 6-inch diameters can choose the bending direction they use most. With multiple tool stack capability, Elect benders can produce fixed and variable radii in a single setup. The all-electric operation provides energy-efficient production and eliminates the need for hose and piping associated with hydraulic systems. This simplifies maintenance and improves reliability for more consistent bending. Elect benders are available with manual or automatic loading.

BLM Group, Novi, Michigan, 248/560-0080, blmgroup.com.

The Strippit V30 1550 is a heavy-duty, 30-metric-ton turret punch press featuring a 200 inch X axis. The Strippit V30 1550 is engineered to allow the processing of worksheets up to 200 inches long by 60 inches wide without multiple sheet repositions, excessive sheet handling or extra shearing operations. By reducing part-handling time, punching and forming operations are more productive and cost efficient. The ability to process a large sheet size also reduces welding and other secondary tasks, lowering costs.

LVD North America, Akron, New York, 716/542-4511, lvdgroup.com.

For increased productivity with automated plasma cutting, new versions of the 200-, 300- and 400-amp Ultra-Cut XT high-precision plasma power sources will double cutting output to 400, 600 or 800 amps. Users of these systems can run two systems of the same output independently or together. The Water Mist Secondary (WMS) process, which incorporates nitrogen as the plasma gas and tap water for shielding, produces superior cut quality and a lower cost per cut on stainless steel and aluminum. On stainless steel, the WMS process cuts up to 300 percent faster and lowers cost per cut by at least 20 percent compared to systems that use argon-hydrogen (H35) for the plasma gas.

Thermal Dynamics, West Lebanon, New Hampshire, 866/279-2628, thermal-dynamics.com.