“Locating our manufacturing center here allows us to assemble machines in the U.S. and reduce the need to import them from Europe,” Robert St. Aubin, Bystronic’s president for the Americas, said at the opening ceremony. “This will significantly cut delivery and shipping costs, which is an important advantage, given the current global supply chain constraints. This new headquarters and manufacturing facility is expected to accommodate the company’s projected year-over-year employee growth target of 20 percent for vital operations, manufacturing, administration and support, and project management.” Bystronic employs more than 200 employees in the U.S.

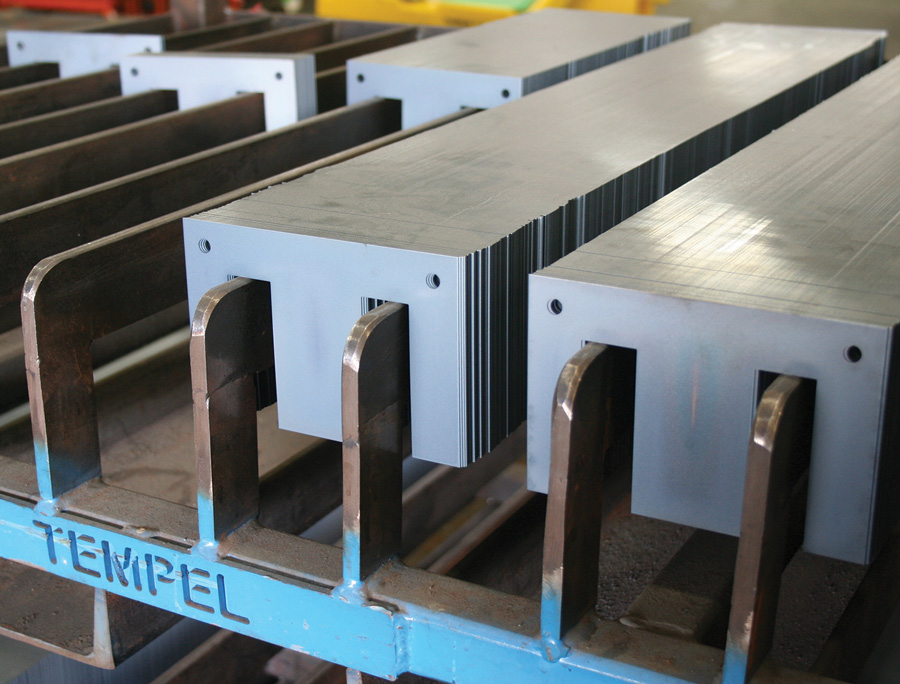

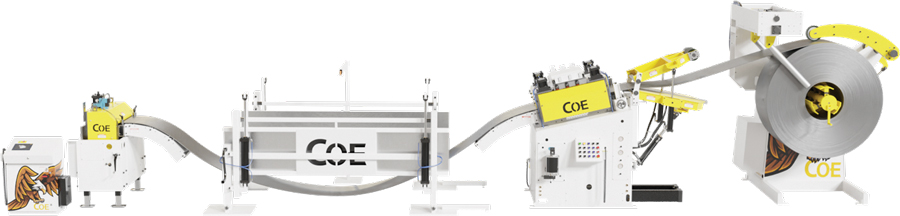

With the assembly of laser cutting machines in the U.S., Bystronic is continuing to develop its market presence and operations network. The next-generation BySmart Fiber 3015 and 4020 laser cutting machines, now with 8kW and 10kW fiber laser power, are the first machines to be locally produced in North America, Europe, and Asia, which strengthens Bystronic’s global product availability and supply chain diversification.

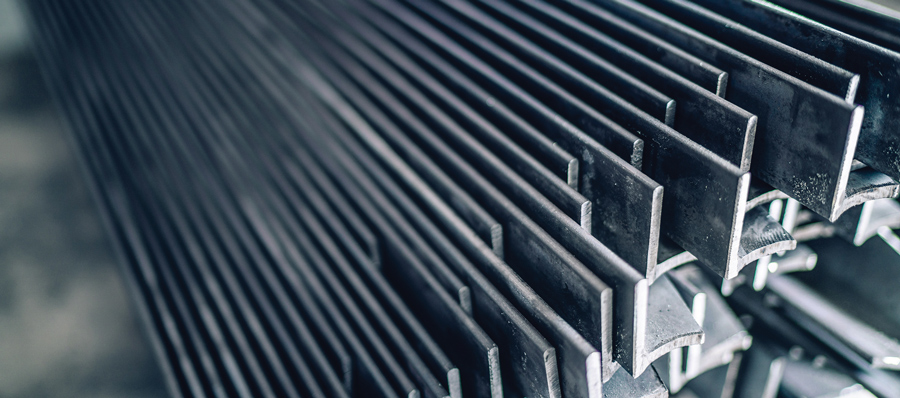

Bystronic’s customer Experience Center and smart factory will demonstrate the company’s entire range of sheet metal processing solutions. Customers will be able to see the latest technologies for laser cutting, integrated automation, storage solutions, flexible bending systems, tube and profile processing solutions. In addition, Bystronic’s software packages covers the entire sheet metal processing chain, smart services. Customized live demonstrations for the software applications are also available.

“The vast majority of Bystronic’s product and service innovations are co-created with customers, suppliers, startups and other partners,” Christoph Rüttimann, chief technology officer of Bystronic, said at the factory opening. “Our goal for the future is to produce more of our sustainable technologies here and continue to help our customers to be at the forefront of world-based competition.”