a nationwide network.

Our team is here, there and everywhere ready to help when you need it. Let us bring your business the ultimate flexibility and competitive edge so you can deliver the most consistent product to your customers!

serving metal service centers, fabricators and OEM/end users since 1945

serving metal service centers, fabricators and OEM/end users since 1945

Features

rganizations representing the metals sector expressed jubilance about the Infrastructure, Investment and Jobs Act (IIJA) that was signed into law Nov. 15.

“Passage of this bill means that now is the time to turn promises into projects,” said Philip K. Bell, president of the Steel Manufacturers Association. “We have an urgent need to modernize … roads, bridges, seaports, airports, waterways and energy distribution systems … to keep the wheels of commerce turning. Every $100 billion of investment can incrementally increase steel demand by 4 million to 6 million tons.”

SMA members are gladdened by the provision that prioritizes domestic production. “We are poised to help our country build back better with the cleanest steel available,” said Bell.

he metals industry has a long history of dealing with volatile materials costs, but the added strains of skyrocketing shipping costs and ever-changing lead times create unprecedented challenges. Disruptions in your supply chain cascade through every aspect of operations, undermining profits and threatening critical customer relationships.

How does your organization respond when a supplier changes the price or extends the lead time again? Does the new data point flow through the system, automatically making adjustments down the line? Or does that critical piece of information need to be entered many times—in multiple systems, spreadsheets and documents?

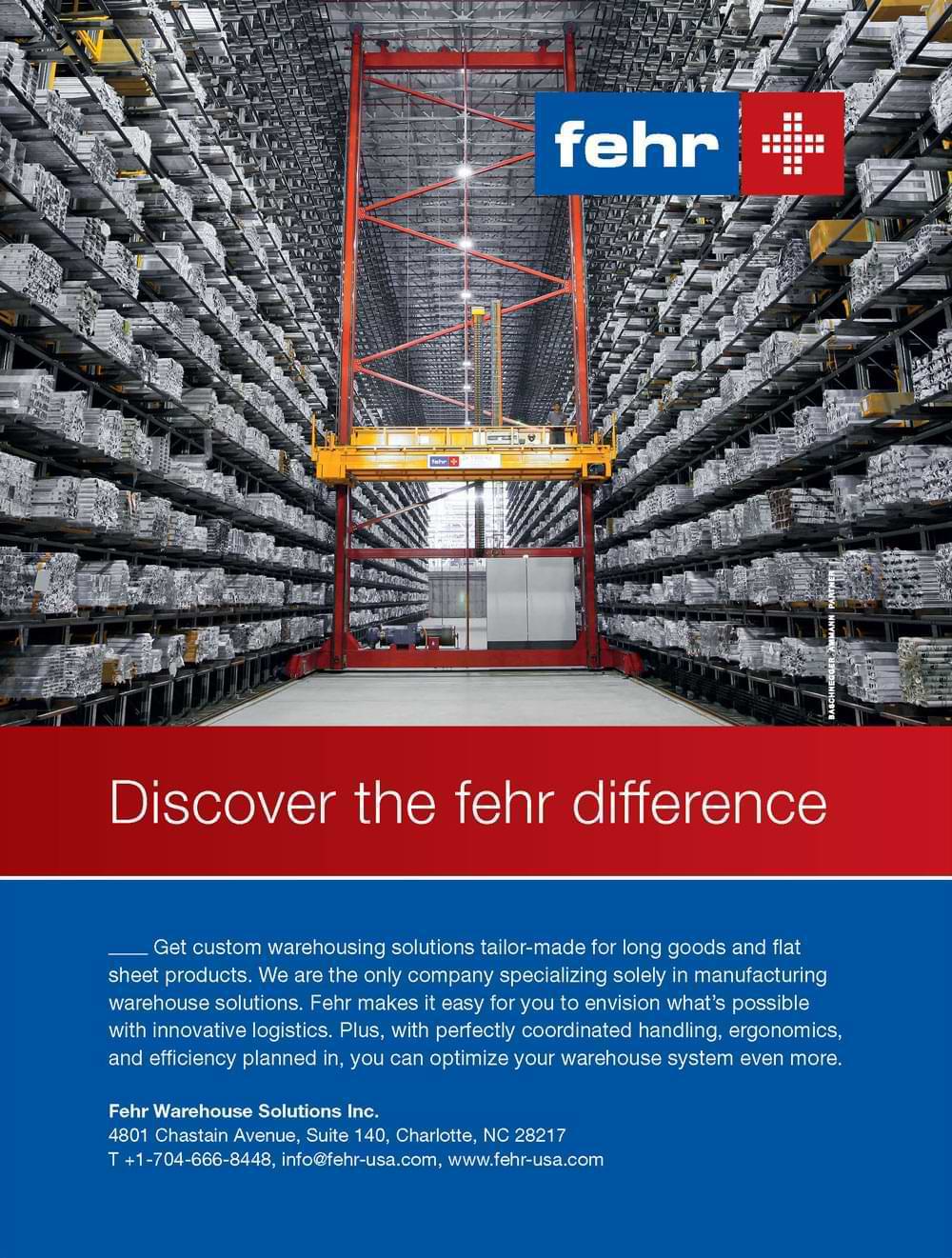

new warehouse system is an investment, and it’s important to envision—and understand—how the system will contribute both to a company’s operations today and its future growth. David Veldung from Fehr Warehouse Solutions discusses how to begin sourcing and optimizing the right warehousing solution through comprehensive concepting and graphic simulations.

What is the first step in the process of taking an idea and shepherding it into the start of a solution?

yperloop is the epitome of a disruptor. It consists of a reduced-pressure tube pathway, a passive magnetic levitation system (Maglev) and a linear electric motor used to propel self-contained capsules (or pods) carrying passengers and/or cargo.

With a hyperloop system, most of the air has been removed from the tubes, dramatically reducing aerodynamic drag. The passive Maglev system levitates capsules off the guideway, reducing or eliminating friction. This low air resistance and lack of friction makes it possible for capsules to reach or surpass 700 miles per hour, exceeding those of commercial jetliners.

upply chain challenges and the resulting chaos are dominating the news—containers, shipping, ports, trucks, railroads, warehouses and worker shortages. According to a tally from Bank of America, supply chain glitches have been the talk of the latest company earnings season, with mentions of the issues by chief executives jumping 412 percent from last year.

minor league ballpark, a mid-rise condominium development and a high school are among the building projects that demonstrate the wide variety of metal cladding options available to architects.

Metal panels are now offered in a panoply of colors, sizes, profiles and textures, provide long-lasting endurance in all types of weather and are environmentally sustainable.

Turbulence

Turbulence

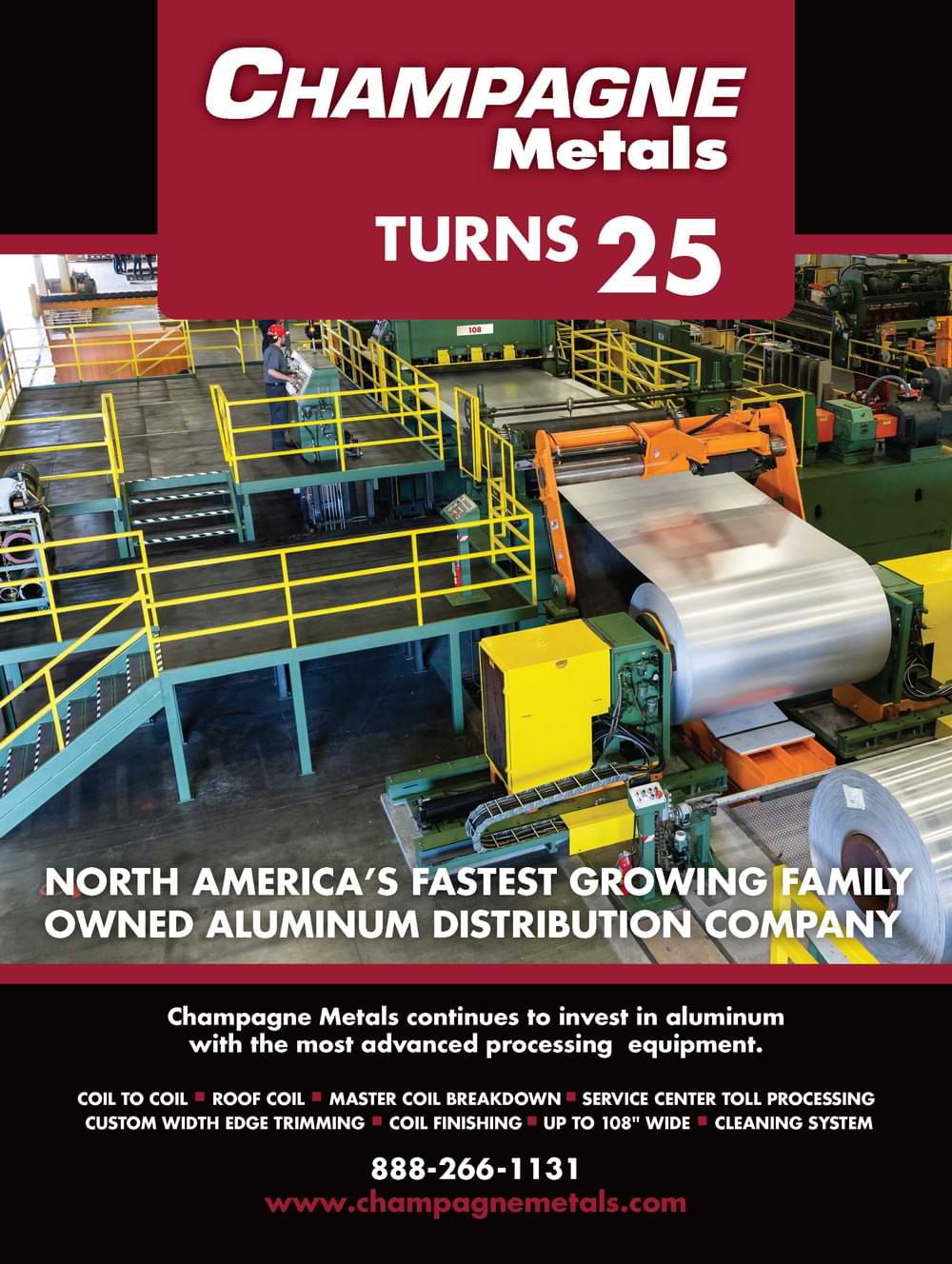

hampagne Metals just celebrated its 25th anniversary in business. According to co-founder, President and CEO Mike Champagne, “We are a family owned, privately held company that invests its money back into the business.”

As the second generation of family moves into leadership roles, he doesn’t expect he’ll be compelled to sell the company. “We have great people coming up. We have the kind of people able to take over for the next generation. My goal now is to hand this off to my family.”

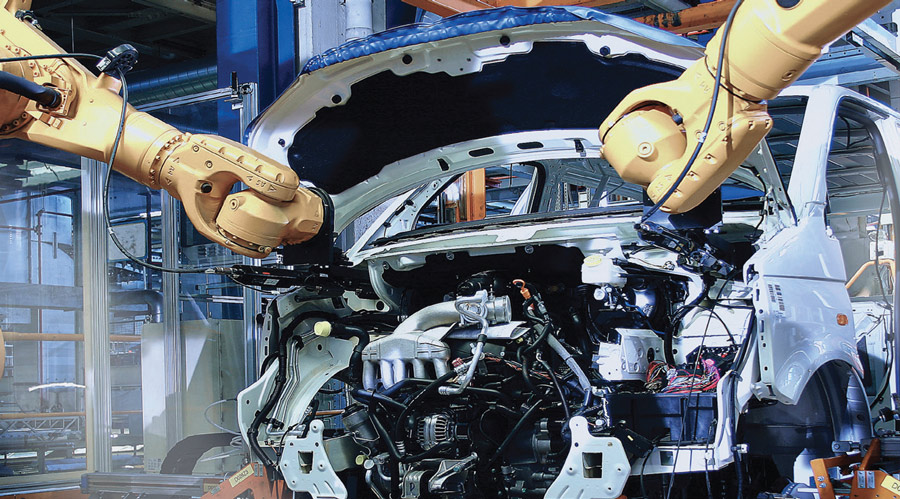

FOR SOME CUSTOMERS, WE DEVELOPED FROM A TIER III SUPPLIER TO A FULL-FLEDGED PARTNER.

FOR SOME CUSTOMERS, WE DEVELOPED FROM A TIER III SUPPLIER TO A FULL-FLEDGED PARTNER.

Bart kroesbergen, joop van zanten

FOR SOME CUSTOMERS, WE DEVELOPED FROM A TIER III SUPPLIER TO A FULL-FLEDGED PARTNER.

FOR SOME CUSTOMERS, WE DEVELOPED FROM A TIER III SUPPLIER TO A FULL-FLEDGED PARTNER.

Bart kroesbergen, joop van zanten

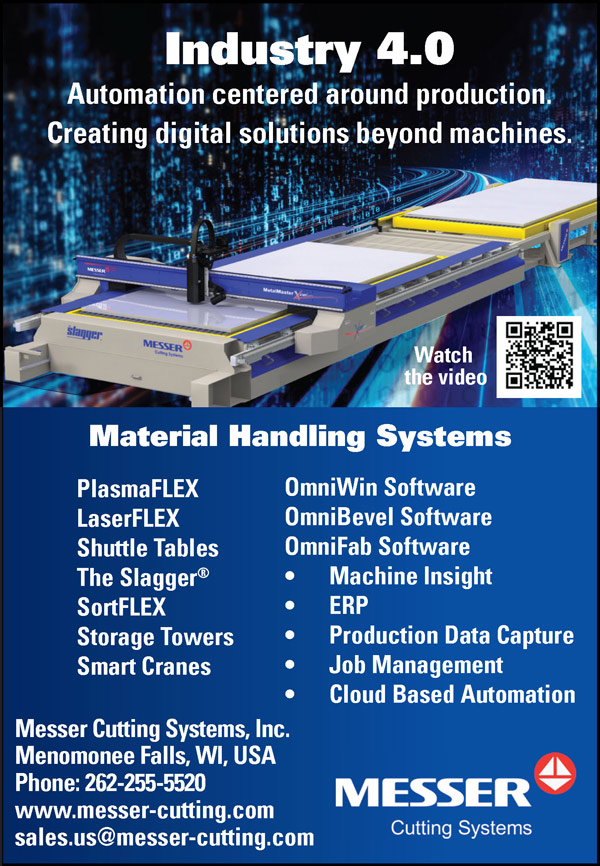

A digital journey

Service center adopts Industry 4.0, sets new standards for a new age

oop van Zanten, a 108,000-square-foot service center in Veenendaal, the Netherlands, services such end user markets as marine, energy, heavy equipment, construction and transportation. Services include plasma burning, welding, bending and machining.

“When I joined the company in 2018, Joop van Zanten was a traditional company that cut heavy-gauge metal; it would certainly have survived by doing that for a while,” says Bart Kroesbergen, managing director. “But in order to stand up to the high cost pressure of Asian markets, to compensate for the lack of skilled workers in the future, and to meet customers’ demands for a fast, high-quality, one-stop shop, a break with the existing situation was needed.”

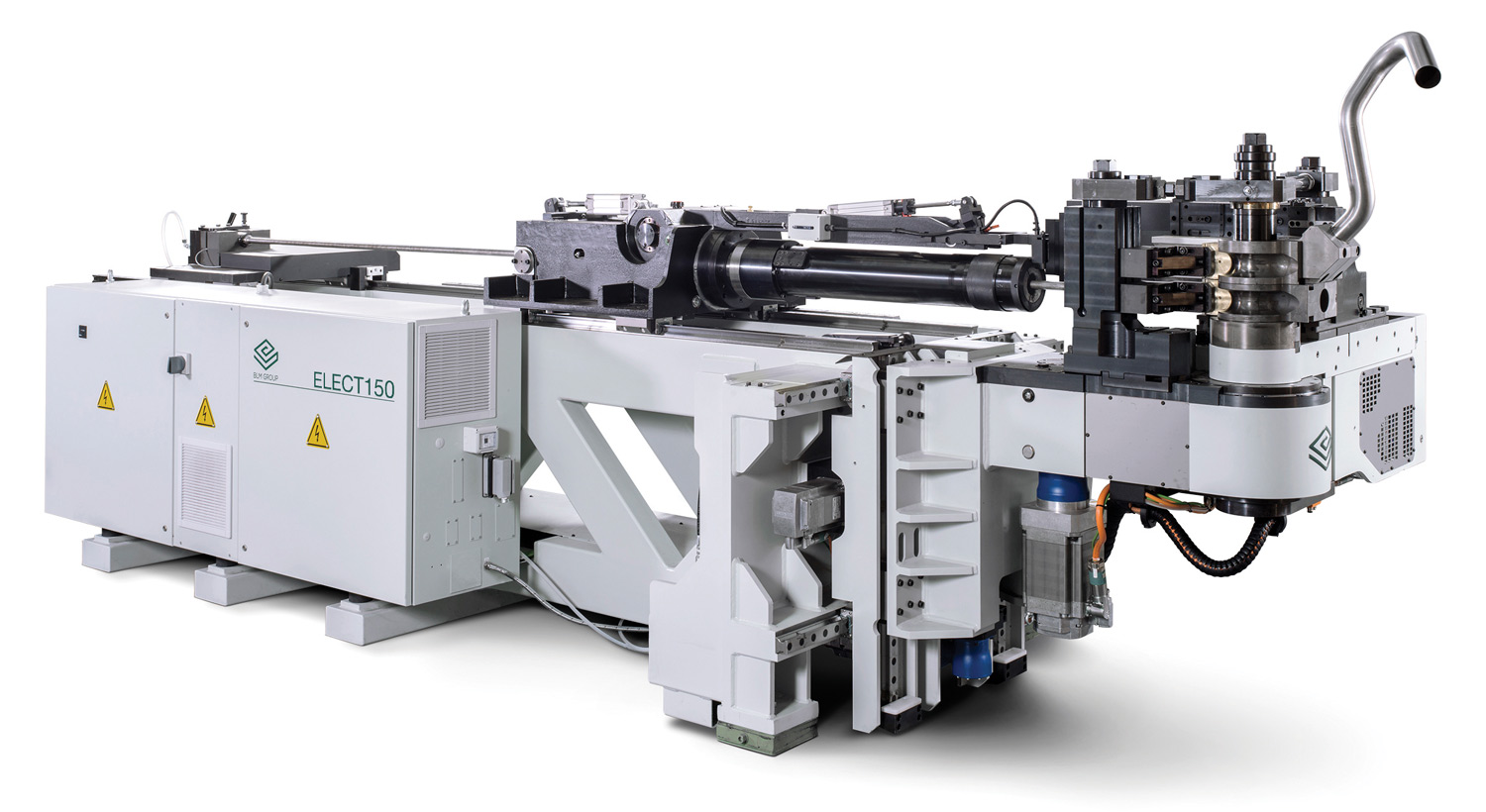

BLM Group has added of left-hand configuration capability to its Elect 102, 130 and 150 bender models. Fabricators processing tubes and pipes up to 6-inch diameters can choose the bending direction they use most. With multiple tool stack capability, Elect benders can produce fixed and variable radii in a single setup. The all-electric operation provides energy-efficient production and eliminates the need for hose and piping associated with hydraulic systems. This simplifies maintenance and improves reliability for more consistent bending. Elect benders are available with manual or automatic loading.

BLM Group, Novi, Michigan, 248/560-0080, blmgroup.com.

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.modernmetals.com

312/654-2309, Fax: 312/654-2323

mdalexander@modernmetals.com

Alaska, Arizona, Arkansas, California, Colorado, Hawaii, Idaho, Montana, New Mexico, North Dakota, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@modernmetals.com

Alabama, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Oklahoma, Pennsylvania, South Carolina, South Dakota, Tennessee, Texas

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@modernmetals.com

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@modernmetals.com

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@modernmetals.com

Modern Metals® (ISSN 0026-8127, USPS 357-640) DECEMBER 2021, Vol. 77, No. 11 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Modern Metals® (ISSN 0026-8127, USPS 357-640) DECEMBER 2021, Vol. 77, No. 11 is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.