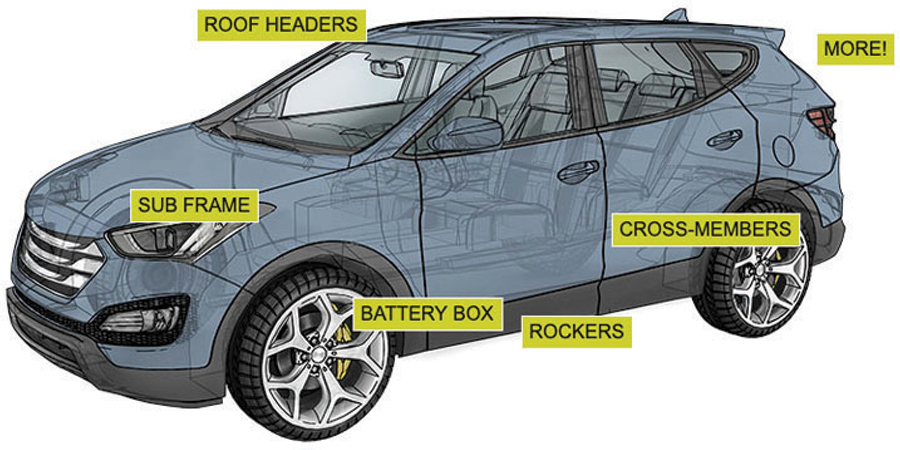

AEC adds automotive resource tool

Aluminum Extruders Council, Wauconda, Illinois, has released a new interactive resource tool on its website for automotive design engineers. The page, AEC.org/AutoSolutions, delivers a wealth of information on the effective use of aluminum extrusions in multiple vehicle components, systems and subsystems, and highlights technical details such as alloys, fabrication methods, performance characteristics and more.

Epcon builds recuperative thermal oxidizer

Epcon, Conroe, Texas, designed and built a large-capacity recuperative thermal oxidizer for a 55-gallon steel drum manufacturer. This system consists of recuperative oxidizer with primary and secondary heat recovery and stainless steel-insulated ductwork to and from various ovens and sources of emissions. The entire system was built, shipped in components, installed, and commissioned by Epcon staff.

Epcon builds recuperative thermal oxidizer

Epcon, Conroe, Texas, designed and built a large-capacity recuperative thermal oxidizer for a 55-gallon steel drum manufacturer. This system consists of recuperative oxidizer with primary and secondary heat recovery and stainless steel-insulated ductwork to and from various ovens and sources of emissions. The entire system was built, shipped in components, installed, and commissioned by Epcon staff.

Nucor to purchase paint line facility in Arkansas

Nucor Corp., Charlotte, North Carolina, has entered into an agreement to acquire the Precoat Metals Corp.’s paint line facility in Armorel, Arkansas. The paint line facility, located near Nucor Steel Arkansas’ sheet mill campus, has a coating capacity of 250,000 tons per year. Nucor considered building a greenfield paint line before deciding to acquire the Precoat Metals plant.

Aluminum processor upgrades software

Champagne Metals, Glenpool, Oklahoma, implemented a full complement of Stratix features such as on-line production planning, coil and sheet cut-to-length processing functions, shop floor receipt of goods, shop-floor production recording and packaging with bar code scanning, and on-line shipment planning. The Stratix software has allowed the company to substantially reduce the amount of paper it consumes. All production planning and scheduling is done on-line, which adds to visibility of sales orders, and at each phase of production until the final shipment.

ASTM presents Award of Merit

ASTM International, West Conshohocken, Pennsylvania, presented its top annual award, the Award of Merit, to Eugene Golebiowski for his contributions to the copper and copper alloys committee (B05). The award, which includes the accompanying title of fellow, is standards organization’s highest recognition for distinguished service and outstanding participation in committee activities. Golebiowski led groups focused on refined copper technology and implementation in product standards.

See more NEWS at www.modernmetals.com

See more NEWS at www.modernmetals.com