We’re relentlessly committed to passionate customer service, offering versatile operations and the industries’ most expansive national footprint.

Come ride the VORTEQ wave of momentum for your coil coating needs! Let’s get started at vorteqcoil.com

Features

ow.ly/9qoq30rkhfE

@HYPEBEAST

020 came in like a wrecking ball. We have the scourge of COVID-19 (the worst four syllables heard in our lifetimes), mass protests seeking justice, murder hornets, a plague of locusts, a tumultuous election, wildfires burning Australia, California, Colorado and Siberia. An explosion in Beirut’s port leveled nearly the entire city. We are experiencing lockdowns, quarantines and hybrid schooling.

Do you remember the near miss Earth had with an asteroid in September? Yeah, it was below the ring of geostationary satellites orbiting our planet. Luckily, it was only the size of a school bus and would probably have burned up in the atmosphere. We lost Sean Connery, Chadwick Boseman, Kobe Bryant and Eddie Van Halen. The Pentagon released UFO videos—no one even paid attention to that.

The good news is we know what we look like with long hair and gnarly beards (like Tolkien’s hobbits and dwarves), we learned to bake bread, we spent waaaaay more time with our children, took long walks in the park and rode bikes. We learned how to disinfect everything. We learned to WFH productively. We also learned how to reach out to others to combat isolation.

Automaker names Worthington a supplier of the year

AEC adds automotive resource tool

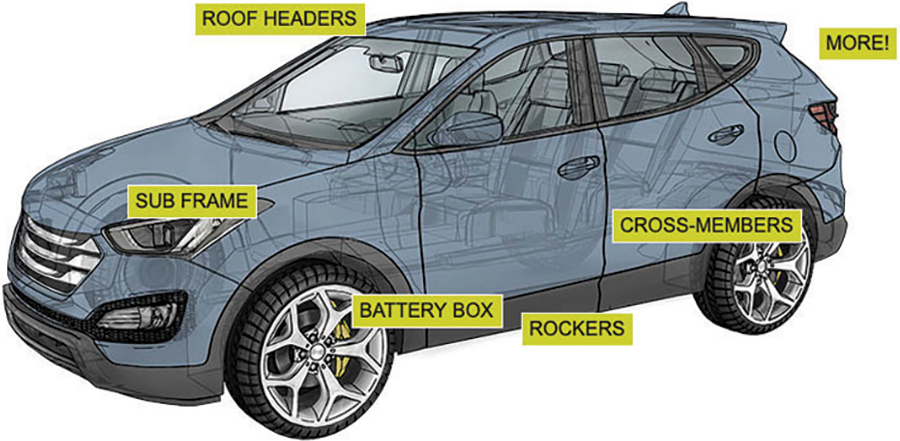

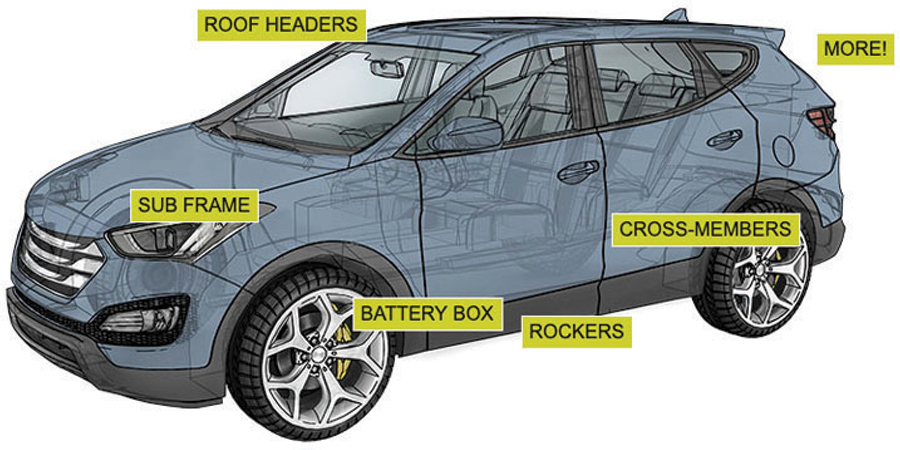

Aluminum Extruders Council, Wauconda, Illinois, has released a new interactive resource tool on its website for automotive design engineers. The page, AEC.org/AutoSolutions, delivers a wealth of information on the effective use of aluminum extrusions in multiple vehicle components, systems and subsystems, and highlights technical details such as alloys, fabrication methods, performance characteristics and more.

Epcon builds recuperative thermal oxidizer

Epcon, Conroe, Texas, designed and built a large-capacity recuperative thermal oxidizer for a 55-gallon steel drum manufacturer. This system consists of recuperative oxidizer with primary and secondary heat recovery and stainless steel-insulated ductwork to and from various ovens and sources of emissions. The entire system was built, shipped in components, installed, and commissioned by Epcon staff.

Epcon builds recuperative thermal oxidizer

Epcon, Conroe, Texas, designed and built a large-capacity recuperative thermal oxidizer for a 55-gallon steel drum manufacturer. This system consists of recuperative oxidizer with primary and secondary heat recovery and stainless steel-insulated ductwork to and from various ovens and sources of emissions. The entire system was built, shipped in components, installed, and commissioned by Epcon staff.

Coe Press Equipment, Sterling Heights, Michigan, 586/979-4400, cpec.com.

Kingspan Insulated Panels Inc., DeLand, Florida, 877/638-3266, kingspan.com.

According to Arjun Aggarwal, Desktop Metal’s vice president of product and business development, Fulop recognized the shortcomings of existing AM methods and brought together inventors and experts in metallurgy, chemistry and robotics from MIT, among other specialists.

“The goal is to make 3D printing accessible to designers, engineers and manufacturers,” Aggarwal says, adding, “We are excited about the future of next-generation Additive 2.0, where you are able to produce parts in volume and at costs competitive with conventional manufacturing.”

n the website quora.com, people replied to an invitation to fill in the blank, “When life gives you lemons, ___________.” One enthusiastic young guy from India responded, “Ask for more. Become a lemon trader. Sell lemons at a price lower than the prevailing market price. Build a company which sells lemons. Become an international lemon selling brand. Have profits in billions. Keep asking for more lemons.”

That, of course, is a winning attitude. Jeff Haas, president of Cleveland Metal Exchange, and Hugh McNenly, president of CME’s Aluminum Division, are two leaders of a team that went through some dark days before they could figure out what to do with the “lemons” given to everyone by the coronavirus outbreak.

In the beginning of lockdowns, during early spring, barely controlled chaos ruled the day. “We worked from home almost three months. I would get a call from one sales rep, then another, then I would call the first one back, then the other. I was spinning in circles, and my head would pop off at the end of the day,” Haas recalls. After being pushed out of his home office into the basement by his young son, “I turned into Jack Nicholson from ‘The Shining,’” he jokes. “But what came with that was creativity.”

[The texas branch] has grown, helping support existing customers and we have won new business.

[The texas branch] has grown, helping support existing customers and we have won new business.

he team at Christy Metals is no stranger to economic cycles. In business since 1964, the master distributor of nonferrous metals in strip, sheet, coil and bar has seen many ups and downs, although the cause of the current situation—a global pandemic—is novel.

Nonetheless, Vice President Lance Shelton, who also serves as president of the Copper and Brass Servicenter Association, keeps his eye trained on gradual growth.

For example, the company built out an additional 20,000-square-foot manufacturing space in its El Paso, Texas, service center and installed a slitting line. “It is light gauge. We go from 0.005 to 0.020 and it’s 12 inches wide for small specialty items,” including grade 260 brass and grade 110 copper, Shelton says. Producing strip in Texas means Christy doesn’t have to ship from its Northbrook, Illinois, headquarters and can deliver just in time throughout Texas and into the maquilladora manufacturing sector across northern Mexico.

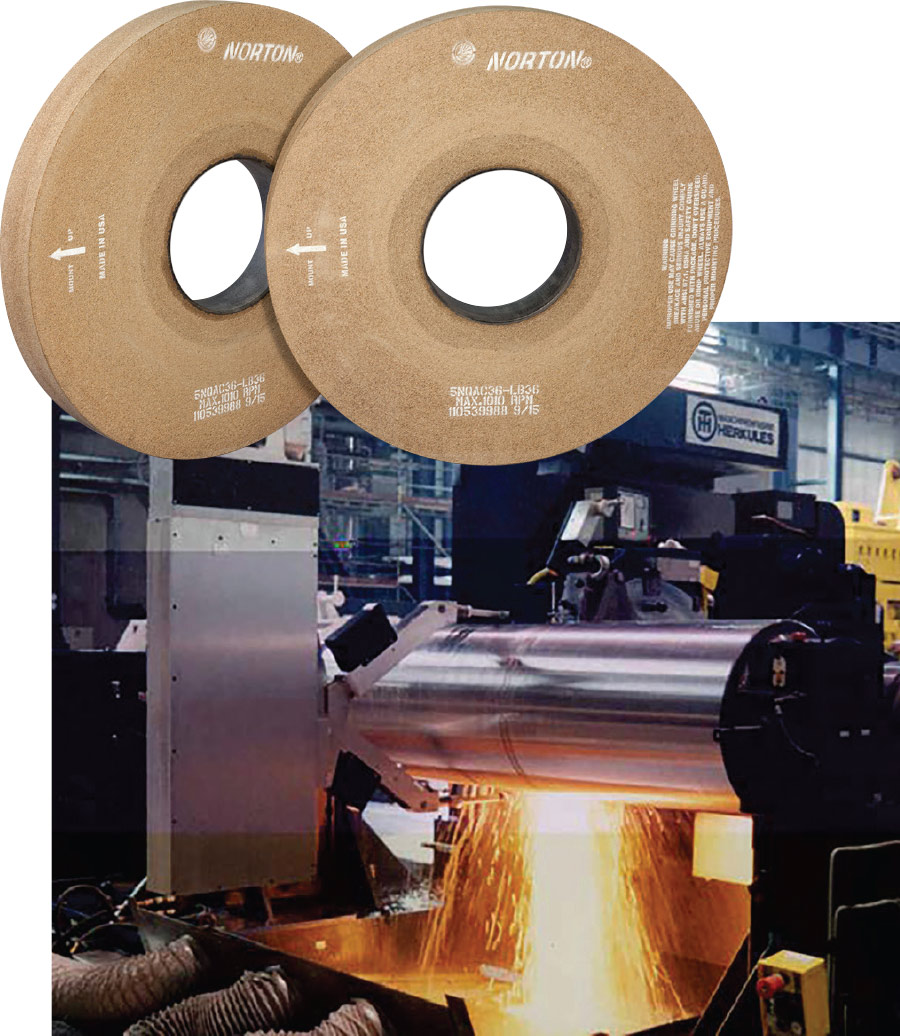

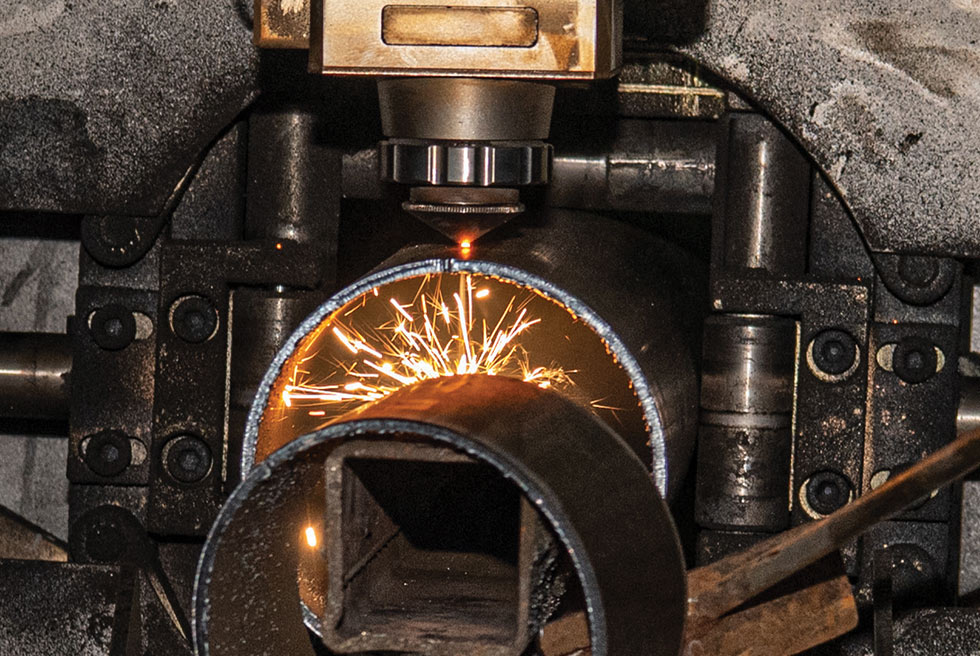

rollgrinding

Norton | Saint-Gobain Abrasives

aving a good roll grinding system is important for mill operators to efficiently and effectively make high-quality steel rolls. However, some mills may find themselves trying to catch up with the latest technology in order to stay competitive. Although an older roll grinder may run well most of the time and, for the most part, produce fair rolls, it might not keep up with demand.

To improve productivity, it may be wise to consider upgrading or replacing outdated roll grinding equipment. Before deciding whether to rebuild or replace an existing roll grinder, there are five important factors to consider:

Advertiser Index

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.modernmetals.com

312/654-2309, Fax: 312/654-2323

mdalexander@modernmetals.com

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@modernmetals.com

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Oklahoma, Pennsylvania, South Carolina, South Dakota, Tennessee, Texas

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@modernmetals.com

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@modernmetals.com

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@modernmetals.com

Modern Metals® (ISSN 0026-8127, USPS 357-640) December 2020, Vol. 76, No. XX is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Modern Metals® (ISSN 0026-8127, USPS 357-640) December 2020, Vol. 76, No. XX is a registered trademark of Trend Publishing Inc. Modern Metals® is published 11 times a year by Trend Publishing Inc., with its publishing office located at 123 W. Madison St., Suite 950, Chicago, Illinois 60602, 312/654-2300; fax 312/654-2323. Michael J. D’Alexander, President, Trend Publishing Inc. Copyright 2020 by Trend Publishing Inc. All rights reserved under the United States, International, and Pan-American Copyright Conventions. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means—mechanical, photocopying, electronic recording or otherwise—without the prior written permission of Trend Publishing Inc. This publication is sent free of charge to qualified subscribers. Single copies $14. Paid subscriptions in the U.S. $125/year. Canada, $145/year. Foreign subscriptions, $180/year surface mail and $260/year air mail. If interested in a free subscription go to www.modernmetals.com to see if you qualify. Periodicals postage paid at Chicago and additional mailing offices. POSTMASTER: Send address changes to Modern Metals® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.