potential

here is a scene in 2002’s Spiderman where young Peter Parker discovers his powers: Barbed cilia emerge from his fingertips so he can climb walls, he can leap from rooftop to rooftop and, finally, he’s able to throw web silk into the air.

Similarly, Bergsen Inc. wanted new tools to empower its data collection, analysis and actions and to empower its customers to use information wisely and efficiently, as well.

Bergsen distributes carbon and stainless steel and alloy long products to the machining, aerospace and automotive industries. Founded in 1974, the Santa Fe Springs, California-based service center performs heat treating, sawing, turning, centerless grinding, planing and trepanning.

“We switched over because that system was written in DOS, and Microsoft said they wouldn’t support DOS anymore. We bought MetalTrax,” which was used for nearly 20 years.

In April 2018, Bergsen installed Enmark Systems’ Eniteo software, made specifically for metal service centers.

“It takes a lot of front loading—completely our fault because we were busy selling steel—but we went live April 1, 2019,” Sharpe says.

there are many more options for looking up information … Our people are using those tools.

there are many more options for looking up information … Our people are using those tools.

Buy-in was swift, both from the departments at Bergsen that are using the system, and the company’s customers, yet the landscape has changed.

“Just in the first two months of 2020, I have never been more confused about whether my company is having a busy day or a slow day, because our phones don’t ring like they used to. You have to go into [the Eniteo system] and look at incoming orders.

“At one time,” Sharpe says, “forty percent of our quotes were over the phone. Today it’s more like 15 percent, but that varies day to day.”

The kinds of inquiries and orders that come in are different, too, based on changing market dynamics.

“Among many of the customers we have worked with in the past, we don’t sell as many bundle quantities. Quote quality (now versus the past) is about the same for those seeking stocking and immediate needs. In today’s world, it seems there is a lot of speculation going on, just like the stock market. People keep their inventories low so when they order metal, they want it now, for tomorrow’s delivery.”

As the company prepared to switch over from the old software to the new, Enmark provided one week of training with Bergsen’s outside IT staff and the entire workforce. Later, Bergsen brought in one of Enmark’s employees for a couple days “to conduct additional Phase B training,” says Sharpe. “I have someone coming in next week for Phase C, where we are getting more deeply into the system.”

- Advanced quote/order entry

- Prospect/customer management

- Quote/order profit analysis

- Advanced branch control

- Consistent pricing control

- Customer financial history

- Customer part specification

- View physical/MTR properties

- Material status control

- Integrated linear nesting

- Credit warning and quality hold system

- Customer order release system

- Track quote-to-order ratio

- Customer material usage profile

- Order duplication

- Forecast future sales

- Document attachment

- E-mail, fax and print directly

- Advanced quote/order entry

- Prospect/customer management

- Quote/order profit analysis

- Advanced branch control

- Consistent pricing control

- Customer financial history

- Customer part specification

- View physical/MTR properties

- Material status control

- Integrated linear nesting

- Credit warning and quality hold system

- Customer order release system

- Track quote-to-order ratio

- Customer material usage profile

- Order duplication

- Forecast future sales

- Document attachment

- E-mail, fax and print directly

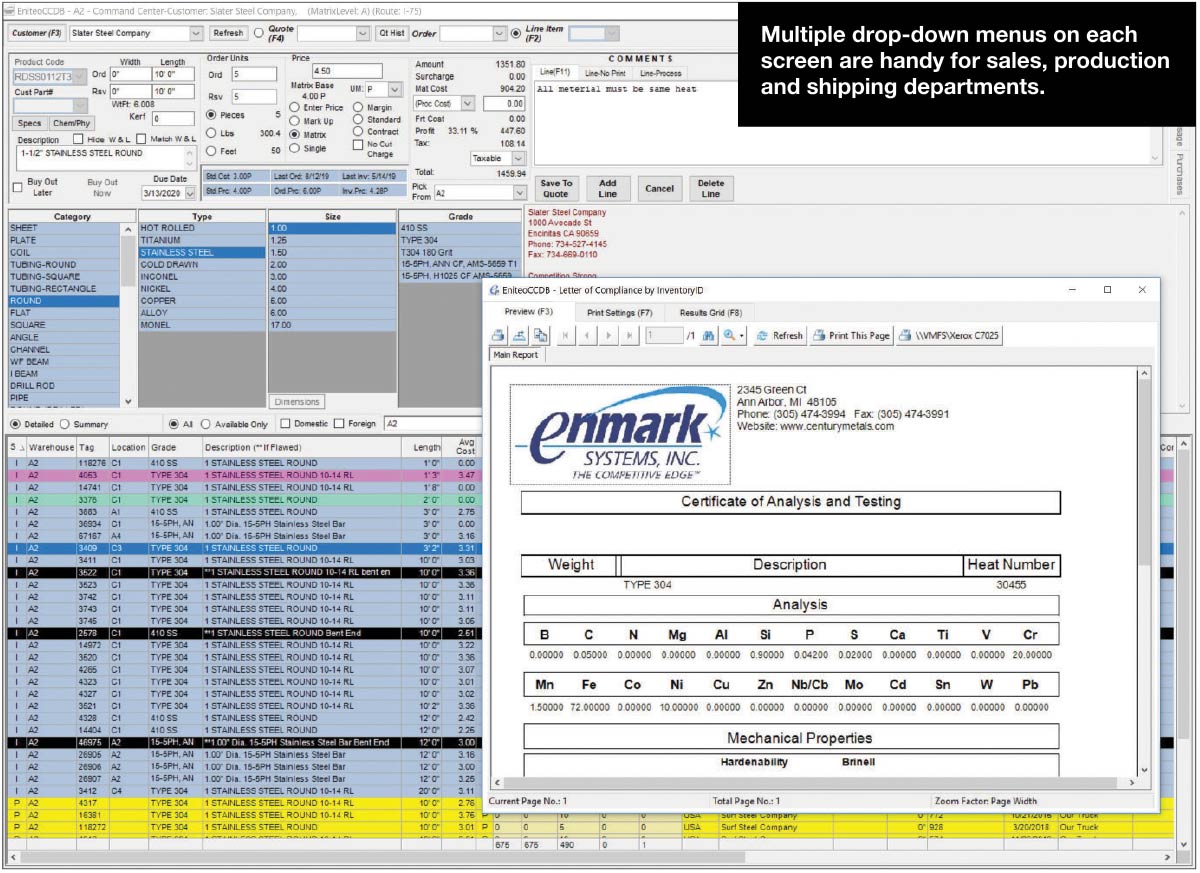

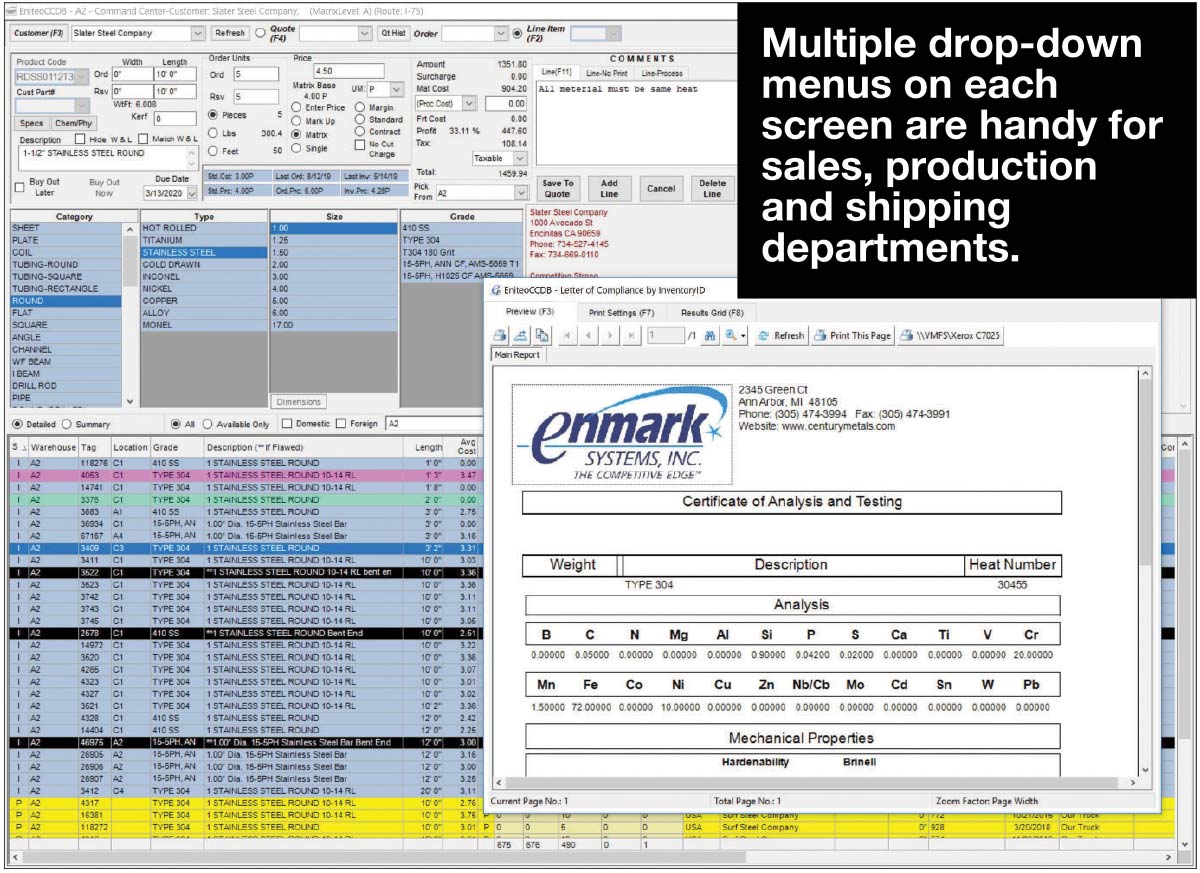

There is also a color coding system that allows employees to instantly identify stock items.

“In our system, we post surplus items that haven’t moved in, say, 50 days. We can study the item and put it on an excess list. It will change the color of the stock. Yellow means the item might have a productivity flaw—it is scratched or bent. We can indicate ‘Do Not Replace.’ If we put an item on excess, the color is blue and sales knows they can adjust price a little bit to get rid of it.”

As for the Eniteo system as a whole, “We are only going to do more the longer we use it. We learn more every day.”

The Eniteo software manages sales, accounting, reports, production, inventory control and bar coding, purchasing and receiving, shipping and billing, and numerous subsets of daily activities.

“There are so many features. The most impressive part of our software is the command center (see sidebar, page 31). It’s a tool for salespeople that gives them access to all information in one location—inventory information, customer information, sales history, quote history, test reports. You don’t have to jump around from module to module.”

“We have a customer portal, WebAccess,” which facilitates metal centers’ ability to provide greater visibility to their clients. “It gives customers 24-hour access to material test reports, open orders/order status and open accounts receivable,” Upell says.

“We do see a move toward e-commerce in the metals industry. Several years ago, we developed an API (Application Program Interface) that allows web orders to flow seamlessly into the Elite system. We have a few customers currently taking advantage of this but we see the demand for e-commerce greatly increasing in our customer base.”

“One of the keys to Enmark’s success is “constantly adding features based on metals customers’ requests and to take advantage of new technologies.” Upell cites the bar coding module as one example. “Our customers who use it cite a drastic reduction in user error, and that makes their business more efficient.”

As for Bergsen’s experience, “One piece of advice I would give anyone doing the switchover is to do a lot of front loading and get a key person in there,” says Sharpe. “Put in all the data, part numbers, etc. Take the time to get it loaded, be prepared to go live and to take it forward,” he adds. “Any new system causes stress, but today we are all pretty comfortable with it.”

Enmark Systems, Ann Arbor, Michigan, 800/594-9025, enmark.com.