utomation is efficient, but it isn’t a silver bullet. It has to be applied with thought and purpose. Microsoft co-founder Bill Gates has suggested that automation applied to an efficient process will “magnify the efficiency,” while “automation applied to an inefficient process will magnify the inefficiency.”

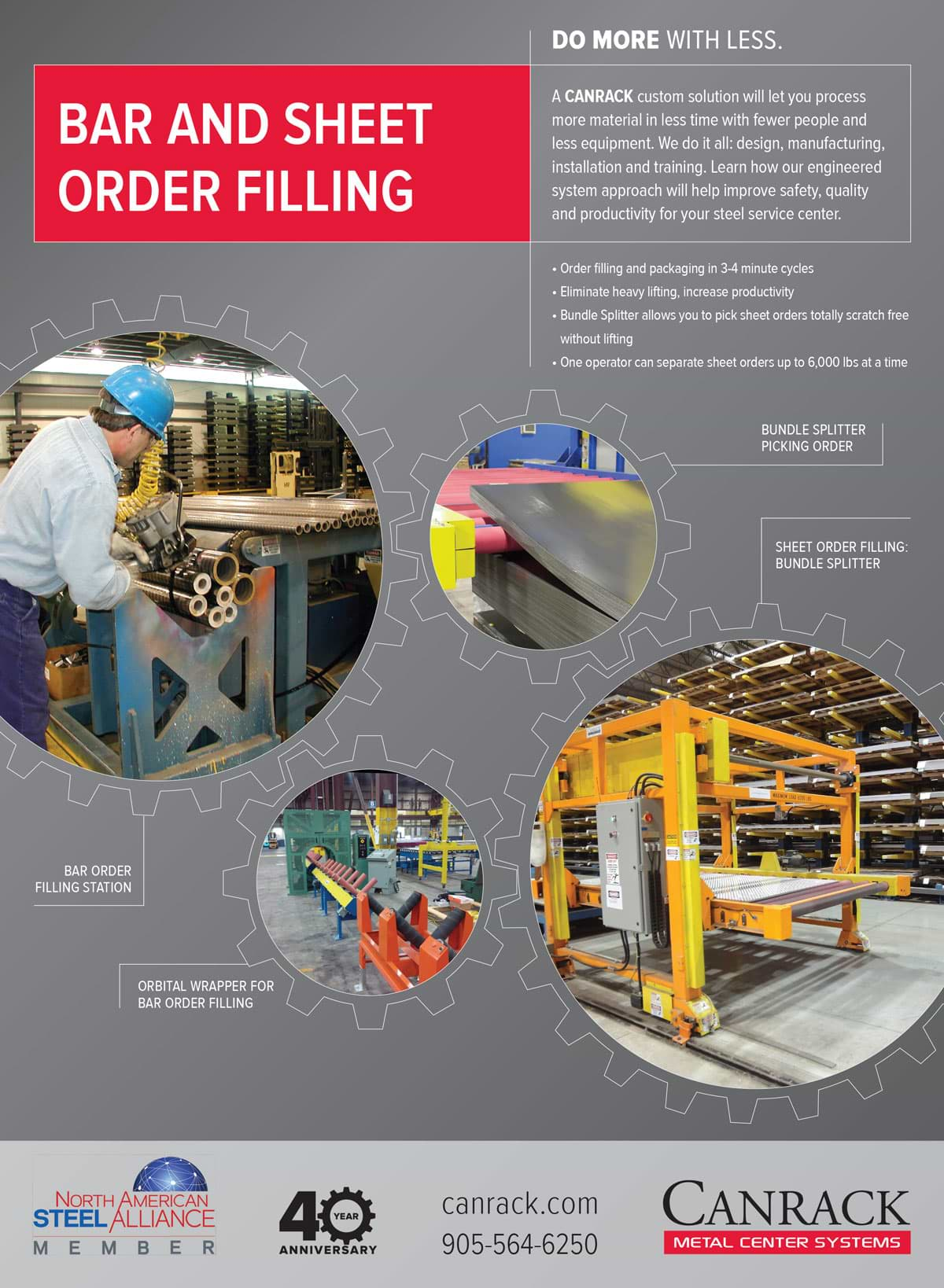

As companies strive to move material through operations quickly and efficiently, conveyors and packaging systems can help eliminate bottlenecks and manual labor when properly implemented. According to Commerce City, Colorado-based Steel Storage Systems, a designer and manufacturer of custom storage and handling equipment, a good conveyor system will increase productivity and improve safety.

“A properly devised system will not only increase output but also can have downstream benefits such as better personnel and crane utilization. We often arrange a system to serve multiple machines or where one operator can effectively run two machines simultaneously,” a company spokesperson says.

Steel Storage Systems builds individual conveyor components and complete integrated systems to complement saws, cut-to-length lines, order filling stations, beam splitters and other metalworking processes. These components include idler and powered roller conveyors, transfer conveyors, cross conveyors, measuring systems, accessories and custom conveyor systems.

A key factor to evaluate when prescribing a system is the volume coming through the line. Steel Storage Systems advocates that a machine operating just a few hours a day requires a minimum of conveyors, whereas machinery running multiple shifts can justify a more comprehensive system. Both systems increase output and value-added revenue by improving handling.

Not properly defining the application can lead to an inadequate solution, e.g., handling a 12-inch-diameter bar is significantly different than a 12-inch-wide beam. Experienced customers will consider features that add productivity, make it more convenient and safer for the operator, and withstand the rugged environment of handling metal.

A common misperception is comparing conveyors by their cost per foot. For example, a 10-foot-long powered roller conveyor will have a much higher price-per-foot cost than a 20-foot powered section that would spread the same drive cost over twice the length.

“Plant layout, logistics issues, types of handling and controls are critical as well. We collaborate with the customer to learn their objectives and concerns. The combination of their input and our expertise is what determines the best conveyor system,” the spokesperson says.

Steel Storage Systems tailors each system to match individual needs, from something as basic as the height of the conveyor to the requirements of the application and layout. Most installations don’t require a significant reconfiguration, but layouts are fitted to the particulars of the plant, such as building columns, walkways and the existing machinery and inventory area.