ue to limited finances, hundreds of small to midsize service centers, processors, fabricators and job shops must do more with the equipment they’ve got, even at the peak of a cycle, in order to remain competitive and grow.

Butech Bliss, Salem, Ohio, has been in business 37 years. Its founder and President John Buta formed Butech after designing and engineering metal processing machinery for others, including E.W. Bliss and Paxson Machine Co. Butech later purchased the assets of Bliss and, this past autumn, acquired the assets of LM Equipment & Design Inc. and Lehmann Mills.

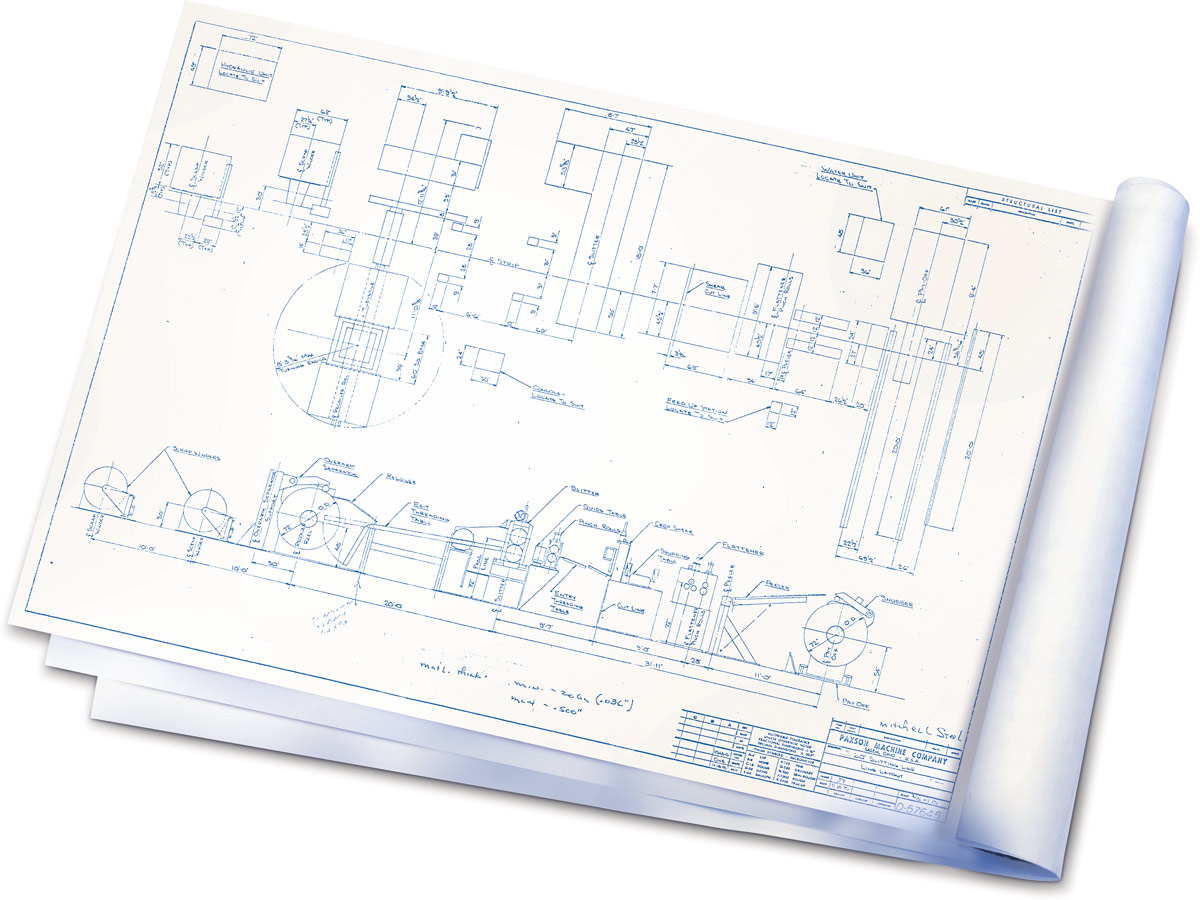

Besides a manufacturing plant, existing equipment and the spare parts inventory, this latest acquisition contains a treasure trove of highly useful intellectual property, according to Buta and his son, Executive Vice President Jock Buta. That includes original detailed drawings of Paxson machines dating back to the 1940s plus customer records, production cost records and sales records.

A mechanical engineer, John Buta worked for Bliss in the 1960s and for Paxson from 1970 to 1985, so he was not only familiar with the machinery but he also helped to design slitting, cut-to-length and leveling lines for Paxson. He introduced technical innovations that are now industry standards, such as the hydraulic leveler. “During the period I was there, Paxson built 150 to 200 lines, many with designs that set performance records for customers. We shipped the equipment worldwide,” he recalls.

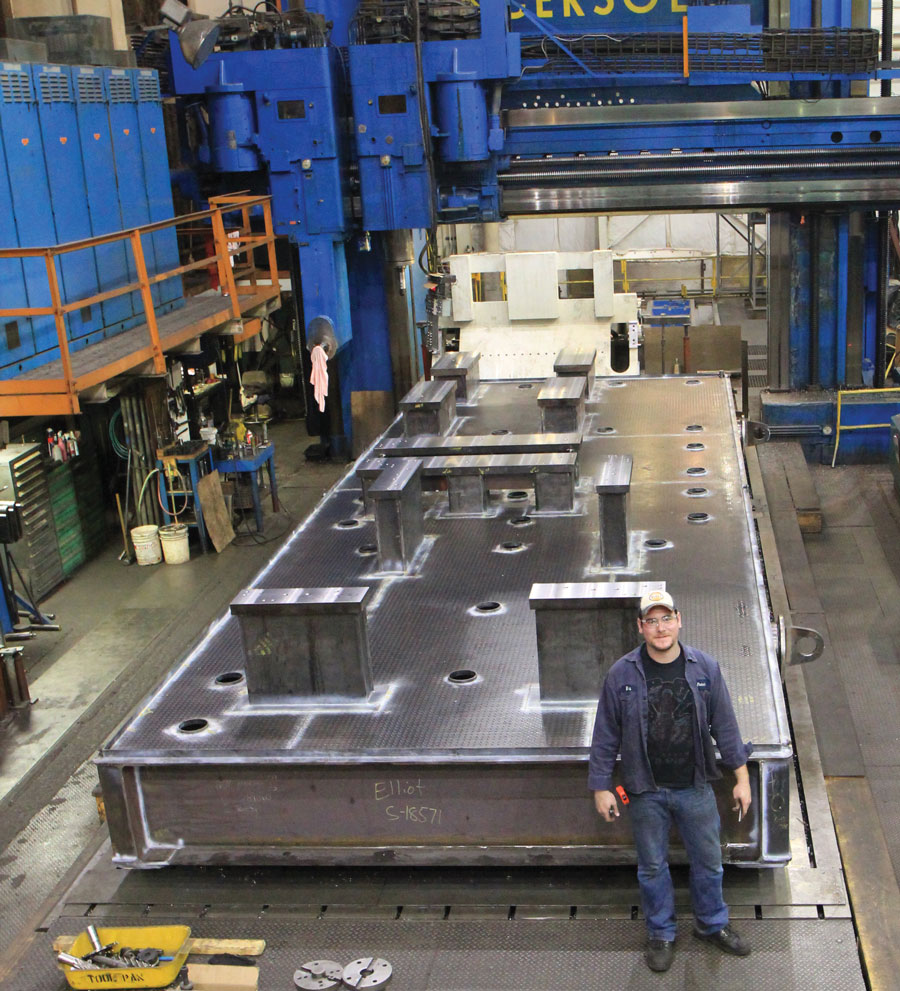

They work in the 45,000-square-foot Lehmann Mills plant in Salem. “It’s an old building but still usable and has decent machines” on which it manufactures equipment, John Buta says. The facility will continue to build and service dispersion mills (used for mixing, dispersing and dissolving liquids such as paints, cosmetics, ink and chemicals) as well as parts and service for the vast number of Paxson equipment installations.

Jock Buta says this plant has “specialized roll grinding machinery that gives us the capability to regrind rolls for all brands of dispersion mills, including Lehmann Mills machines and, in addition to rolls for Butech, Paxson and all makes of coil processing equipment.”

The company acquired a seventh manufacturing building last year to relocate its machinery rebuild activities, in order to make space in the main plant for assembling new equipment. “We dedicated a separate building where we have a team that disassembles and inspects the used machinery, who know what needs to be replaced, and can do it very quickly. Some of our customers have an emergency situation,” Jock Buta explains. “The longer they are without the equipment, the longer they are not making product and earning money.”

Plenty of Butech Bliss customers have an assortment of other brands of metal processing machinery on their production floors, and the company has long repaired and serviced those machines. Now, says Jock Buta, “customers can come to us with their Paxson equipment as well. Because we have the full library of drawings, it allows us to more quickly repair and bring them back to original operating specifications.”

We wanted to pursue an opportunity, keep people employed and keep the products going.

We wanted to pursue an opportunity, keep people employed and keep the products going.

“As we are reaching out to Lehmann customers to tell them ‘we can attend to your needs and have even more services,’ they immediately ask, ‘what else can you do?’” says Jock Buta.

With any piece of machinery that must be rebuilt, the team must take it apart and figure out how to make the replacement parts. “Now we have the whole drawing set, which helps us determine the original specifications that we have to get back to,” he says. “If you just take it apart, clean it and measure it, there is a limit to what you should do to refurbish it. But if you have original drawings, you know the intent.”

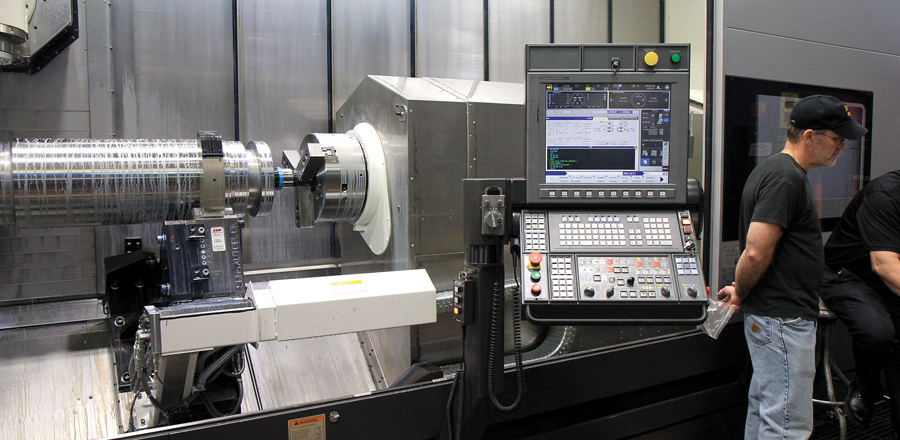

“Naturally, automation and electronics are the fastest-growing technologies,” Jock Buta says. Another area of growth is safety requirements, such as dedicated controls, gates and sensors. Customers want “additional functionality to increase safety and performance, to lower power consumption and provide faster response times. There is a wide range of automation-related upgrades that can be done,” he says. “We have our own automation engineers that live and breathe safety requirements and how to install those power systems, sensors and drive technologies.”

For example, says John Buta, Butech builds levelers for shape correction. “Older machines don’t make the material as flat. We build some of the most sophisticated levelers. Lehmann Mills didn’t have the ability to do that. Also, stretchers are being retrofitted in lines to achieve flatter, more stable sheets and plates,” he says. Another possible upgrade is coil feed systems. “Paxson equipment can handle some coils, but not the largest ones.”

This division also manages a special parts stocking program. “We call it Fast Track. It’s basically like Amazon fulfillment. We’ve streamlined the order fulfillment process so we can ship certain parts out the same day they’re ordered,” he says.

“We have determined what parts are most valuable—long lead manufacturing components, knives, hydraulic valves and seals, for example—and moments after a customer calls, we can click a button on the computer and the part is put in a box and shipped out same day. With the Lehmann and Paxson inventory, we will add some of those parts to our Fast Track program as well.”